In my former life as a software engineer, I’d sometimes experience the following: You’d have a bug in a program. It’d be subtle enough that you couldn’t find what was causing it, so you’d employ the brute-force method of reducing the number of lines of code in the program. There’s a process called “commenting out” where you can make lines or entire blocks of code inactive without actually deleting them. So you’d comment out half the code and see if the problem still existed; if it didn’t, then the problem was in the half you’d commented out. If it did, you’d comment out half of what remained, repeating until the problem went away. The idea was that, once you got down to a small enough amount of code that exhibited the problem, you could either see the problem (and have either your “Eureka!” moment, or your “I am such an idiot!” moment, whichever was warranted) or, you could claim that you’d found a genuine compiler bug, something that had nothing to do with you but instead had to do with the way your presumably flawless code was translated into bits.

But sometimes, in enacting the “remove half, then half again” process, you never found anything wrong; you put all the code back in, and it inexplicably worked. My team and I called this the “Ant in the sugar bowl” scenario: You know, you see an ant crawl into a sugar bowl, you keep removing sugar, you get to the bottom, and… no ant.

Where in sweet hell is your hack mechanic going with this?

I’m beginning to feel this way about the a/c problem in the E9.

To recap:

- I’d retrofitted a/c into the car twenty years ago. It worked okay, but never great.

- Six years ago, on the way to the Vintage, a clevis pin fell of the back of a truck and embedded itself in the condenser but did not puncture it. It made me realize, however, that the condenser was the old serpentine-flow kind, not the modern parallel flow kind. I bought a new parallel-flow condenser, but only got around to installing it two years ago. I was surprised that, when installed, it did not make a big difference in the a/c system’s cooling ability.

- In Part I, I pulled the E9 out of storage in June, turned on the a/c, and found it non-functional. The gauges indicated that it had very little refrigerant in it. Clearly it had leaked out over the winter. I tried but couldn’t find the leak. I topped it up with refrigerant, but noticed that the low-pressure side went really low, like nearly into vacuum, and that both the high and low gauges moved very sluggishly when you shut it off. I felt that this indicated a possible restriction, most likely in the expansion valve. I tore the system apart, removing the console and evaporator assembly under the dash, which is my least favorite repair on any car, ever. There was a small amount of particulate matter in the expansion valve, but not the black gooey mess I expected to see.

- In Part II, I replaced the expansion valve, but when I leak-tested the core and valve with nitrogen, could not get it to hold pressure overnight, and could not find the leak.

- In Part III, I found that the leak was coming from the a/c manifold-gauge set itself. I replaced the leaky gauge and began reassembling the evaporator assembly.

- In Part IV, I replaced the a/c blower motor, which worked when I took it out but then mysteriously died.

- In Part V, I reinstalled the evaporator assembly under the dash, and in doing so, cracked the rare and fragile “intermediate piece” that sits between the assembly and the under-dash. Determined to press on and see if the system got cold, I evacuated and partially charged it, found that it was not getting cold, and saw that the gauges still moved sluggishly when I shut the a/c off. I concluded that something must still be wrong, and that this something must be the compressor or the condenser, and wondered which I should replace first.

I already had a brand-new unused Sanden 508 clone compressor sitting in the garage, so I began to swap it in. When I disconnected the hoses, a big puddle of refrigerant oil poured out, which is unusual.

Unless you have a bone-stock a/c system with an actual spec of how much refrigerant oil it takes, and that system is completely empty, it’s always a good question what the correct amount of oil is to add. Replacement compressors typically come with either four or six ounces of oil in them. Because they always come with Pag oil and I prefer using Ester oil (better for retrofit applications, as it’s more tolerant of small amounts of old refrigerant and oil), I always drain and refill them. But installed compressors don’t have a dipstick, and even if they did, oil gets distributed through the a/c system. If you assume that a system takes four ounces, and that it gets evenly distributed to the four major components (compressor, condenser, receiver-drier, evaporator), a rule of thumb is to add an ounce or two to each new component replaced, but without flushing an entire system and refill it precisely, it’s easy to over-fill or under-fill.

I’d done the work on the E9 in phases. Two years ago I replaced the condenser. I believe that when I did that, I dropped the compressor and completely drained and changed the oil, adding four ounces. Then, last month, I pulled the evaporator and flushed it, and added an ounce to the new one. Seeing this puddle of oil, I wondered if I’d overfilled the system.

Since this time I was only changing the compressor but leaving the other three major components intact, I compromised and filled it with just two ounces of oil. I closed the system up, evacuated it for 90 minutes, and shot a can of R134a into it. Much to my chagrin, it still didn’t get cool, the high-side pressure was creeping up to 25o psi, and the gauges still appeared to move sluggishly back to static pressure when I shut the system off.

Damn. What was next? Replace the condenser? That was the only major component left.

It was very hot in the garage. I came inside to cool off and think.

I need to say that there are reasons for my scattershot approach to this repair, my likely botching the diagnosis, and the fact that it’s dragged on for nearly two months. My 89-year-old mother’s health began to decline dramatically after I got back from the Vintage in May; she passed away in mid-July. I use car repair as a form of therapy, but the 45-minutes-at-a-time-moment-of-Zen-laying-on-of-hands-clear-beginning-clear-end-clear-success-like-when-you-replace-a-windshield-washer-pump kind of stuff is a different animal from correct diagnosis of a subtle and vexing problem. I think I’ve been a victim of my own lack of mental bandwidth, trying to apply bunt-and-run, try-this-no-try-that repairs to something that instead required careful analysis and concerted effort.

I resolved to try to shift gears.

First, were the gauges actually any more “sluggish” than they were when all this began? I couldn’t remember. It’s not like I had videotaped them. I probably should have. I removed the manifold-gauge set from the E9, connected it to my E39, and turned its a/c on, then off. To my surprise, the gauges exhibited a similar slow return to static pressure when the a/c was turned off. Perhaps I was imagining the sluggishness—maybe there was nothing wrong.

Except, of course, the fact that the a/c hadn’t been and still wasn’t blowing cold.

I went back to the garage. It was probably mid-90 degrees and damned humid. I thought that maybe 250 degree head pressures weren’t out of the question… if the system was actually blowing cold. I verified that the condenser fan was working. It was.

I’d bought a replacement condenser (they’re only $45), and it had arrived, but installing it is a non-trivial amount of work. Maybe, I thought, I should just bite the bullet and replace it.

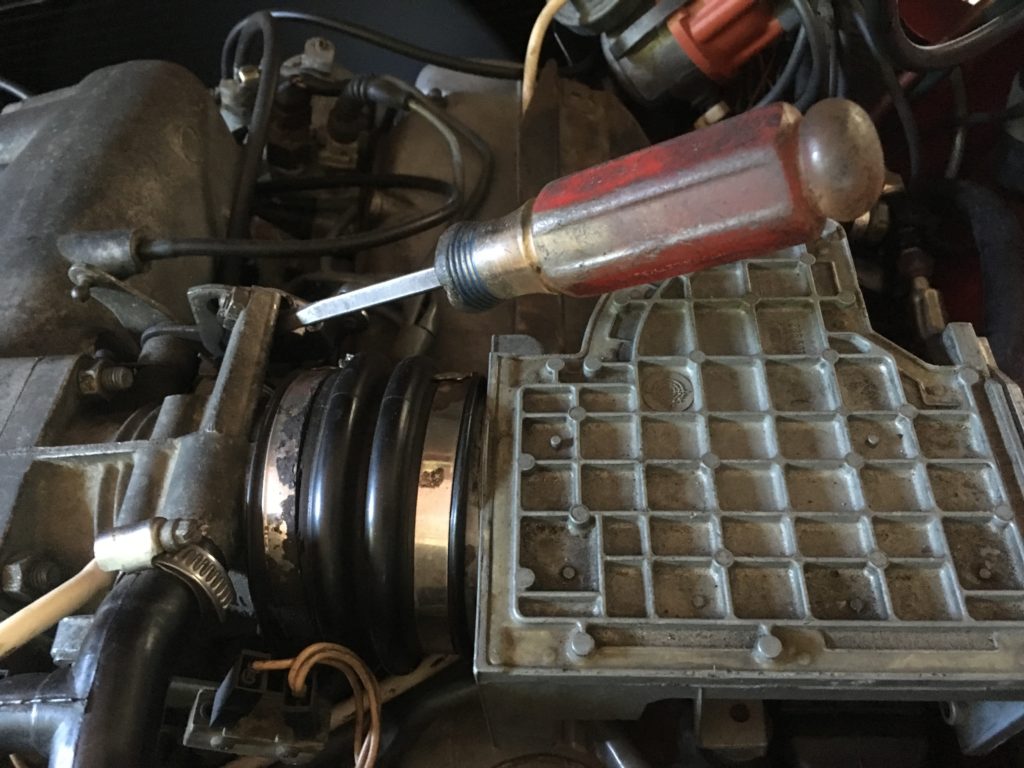

No. Not yet. I re-checked the a/c, but this time, I propped the throttle open with screwdriver to keep the engine at about 2000 rpm. This is generally advised when recharging, but on my vintage cars, I usually just do it at idle, and it’s usually fine.

Increasing idle speed the old school way.

With the rpm up, I could feel the system begin to cool. There was only one can of R134a in it, but it was clearly functioning.

Wow.

Then, something occurred to me: What started all this was the fact that the system was low on refrigerant, which meant it was leaking. Somehow, in my diagnosis and repair, I never knuckled down and found the leak. At one point I determined that one of the manifold gauges was leaking and fixed that, but I never doubled back and tested and repaired the entire system. Provided the leak is very small, this is a separate issue from cooling, but it was still a major oversight.

With the system having one can of refrigerant in it, I pulled out the trusty Yokagawa H-10G leak detector and methodically went over everything. When I brought the detector into the nose of the car, near the condenser, it began squealing. Most leaks are at connections, but those didn’t appear to be the source. It certainly is possible for metal components and hoses to develop pinholes in the middle, but it’s uncommon. Nonetheless, the source appeared to be from somewhere on a six-inch section of the rubber hose coming down from the top of the condenser.

Sometimes, in leak detection, a one-two-three punch is effective. First, use the sniffer to find a general area where a high concentration of refrigerant in the air is setting it off, and localize it as best as you can. Then, switch to using an engineered soap solution like Big Blu (way better than simple soapy water). If that reveals bubbles, then put the detector back on that spot to verify. That’s what I did, and the soap solution found a tiny trail of bubbles, looking like a very small centipede, in the middle of the hose. It was so small that had I simply slathered every component and hose with soap solution, I never would’ve seen it. As I looked carefully on the hose, I found another pinhole up nearer the top. I put the sniffer on both of them, and it went nuts. Gotcha.

Why, you little…

This was one of the hoses from when the system was originally installed 20 years ago, the one running from the compressor’s discharge port to the condenser inlet. I keep hose and standard fittings in stock at the house, but because the parallel-flow condenser was the biggest one I could fit in the nose, I needed to use a short-drop fitting at the top for clearance, and that wasn’t an item I had. So I had to put one on order and wait a few days. If I’d thought about it longer, I would’ve ordered every fitting I need to replace every hose, but I wasn’t thinking that globally.

The short-drop fitting was used to maximize clearance.

When the new fitting arrived, I broke out my Mastercool Hydra-Krimp and built the new hose.

Take these items, squeeze them all together, and…

Voila! You get this!

I installed the new hose, pressure-tested with nitrogen overnight, found it within 2 psi of the starting pressure in the morning (and in a garage that’s 20 degrees cooler in the morning, that’s likely due to temperature-induced pressure drop) evacuated the system, shot in the first can of R134a with the idle raised to about 2000 rpm, and felt the system cooling. I then charged it the rest of the way by watching the gauges and stopping charging when the inlet line to the evaporator sweats and when the vent temperature stops dropping. I haven’t driven it yet, but so far so good.

So, was all of this nothing more than the ant in the pile of sugar? Was there ever anything wrong with the E9’s a/c other than being low on refrigerant due to a few small leaks in a hose and my not having pushed the rpm up during charging? Did I waste dozens of hours and a few hundred bucks and crack a fragile rare piece of the system and replace a compressor for no reason? Does it matter? Do I even care anymore?

Sigh. Sometimes we simply need to survive our own questionable choices. At least the car has working a/c for August. If it breaks again, I don’t think I’ll ever tell anyone. I’ll just drive around with the windows up so no one can see me sweat or hear me curse like a sailor. If you open the door and I mumble something about the problem being caused by an ant that crawled in, you’ll understand.—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com. His next book, Resurrecting Bertha: Buying Back the Car My Wife and I Drove Off From Our Wedding, will be released in the fall.