Last week the reinstallation of the transmission in Zelda, my 1999 Z3 2.5i, was train-wrecked by shipping delays for the pilot bearing, the clutch fork, and the rear main seal. The fork and seal arrived, but the pilot bearing went into that shipping netherworld where USPS tracking showed it just sitting in a distribution center in Boston, fifteen miles away from my house, for a week. To break the log jam, for fifteen bucks I ordered another pilot bearing from Amazon, and it arrived in two days.

It was the right call, as the part I’d ordered from RockAuto still hasn’t arrived.

An oil-pressure-sensor socket was the perfect size to use as a drift and seat the bearing in the end of the crankshaft.

Tapping the pilot bearing in.

Next was the rear main seal. Balancing the carrier on two blocks of wood and tapping the seal out with a flat punch did the trick. I tapped the new one in nice and straight using one of the blocks of wood as a drift.

Primitive but effective.

I hadn’t replaced a rear main seal in a while, and was surprised when I read the instructions and saw that this one talked about using a special tool—a plastic retainer that keeps the lip of the seal from flipping over when you slide it over the end of the crankshaft. I didn’t have the tool, and I didn’t recall ever experiencing this problem when installing a rear main seal. I then laughed when I saw the plastic retainer sitting in the box the seal had come in.

The retainer was pretty handy.

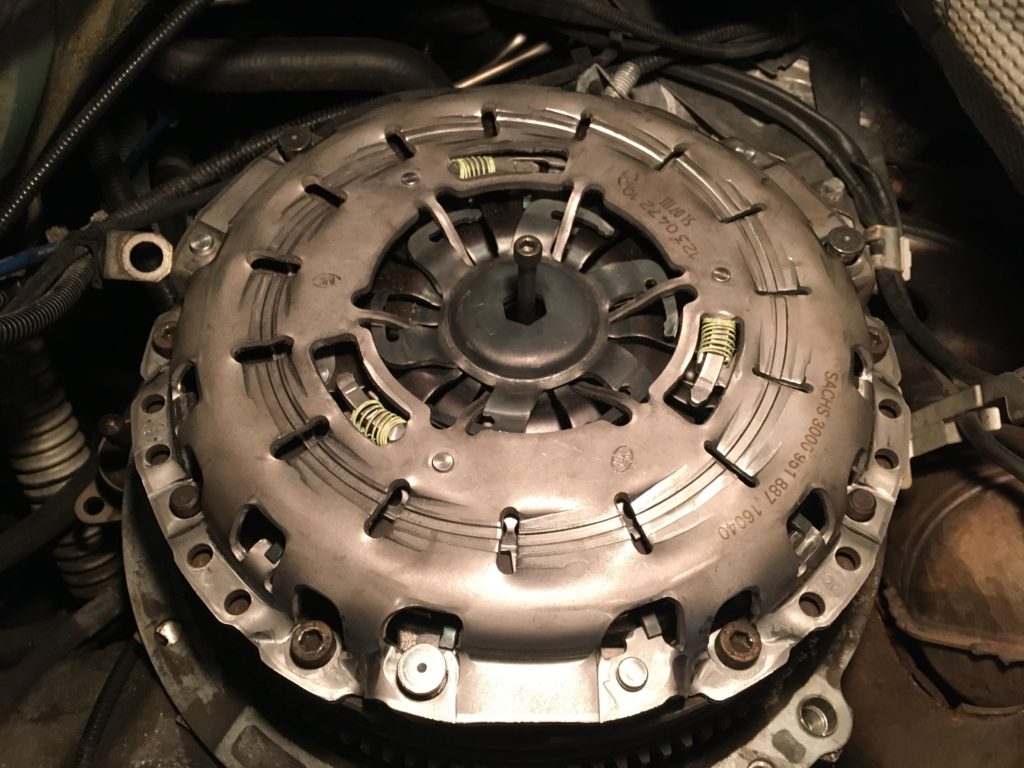

Next were the flywheel and clutch. As I said last week, I had inspected the dual-mass flywheel, found that it only had three teeth of rotational play (well within the five-tooth spec) and no axial play, so I put on a mask, blew the dust out of it, and reused it.

The Sachs replacement clutch came with a retaining plate that kept the springs from engaging and the plate from pressing against the disc. You’re supposed to mount the disc and pressure plate, then use a big Allen key to twist the retaining plate out. The problem is that, as with any clutch, you need to slide the alignment tool into the clutch splines and pilot bearing to center it to receive the transmission’s input shaft. The alignment tool that came with the kit had a thin bolt protruding from the middle of it, so when the tool was inserted, the bolt made it impossible to use the Allen key to remove the retaining plate. Aha, I thought; I need to seat the alignment tool, then back the bolt out of it to allow the Allen key to go into the hole. But with the retaining plate preventing the clutch from engaging, loosening the bolt just made the clutch disc spin. I never did figure out how it was supposed to be used. I finally just tapped the alignment plate with a flat punch to rotate it out, and then withdrew the alignment tool. If someone wants to chime in in the comments, tell me I’m an idiot, and reveal how you’re supposed to deal with this, I’ll be embarrassed but educated for the next time I need to do it.

This was a puzzle.

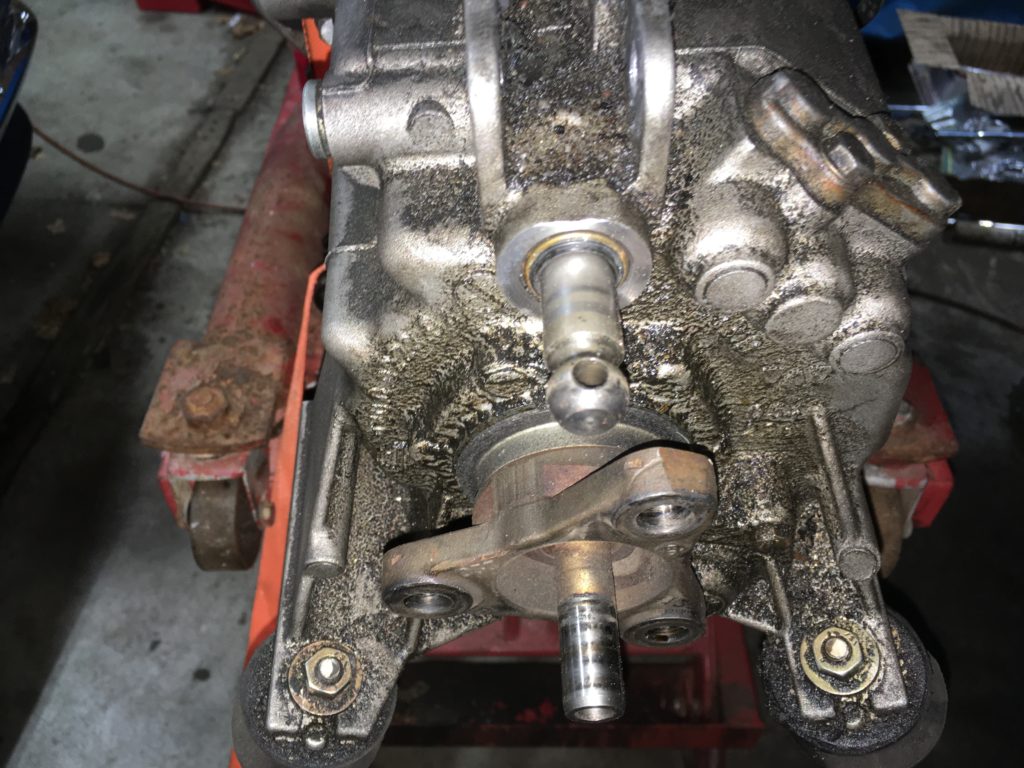

Next, I reassembled the clutch-release mechanism. The destroyed clutch-release bearing (throwout bearing) was what had caused me to pull the transmission in the first place, and the bearing had caused unusual wear on everything it touched, so in went the new sleeve, bearing, fork, and pivot pin. A light coating of the grease that came with the clutch kit was applied to the splines on the input shaft as well as the sleeve and pivot surfaces of the fork.

Installing these new parts, particularly the bearing—which was the cause of this surgery in the first place—felt good.

A Facebook friend had commented that while I had the transmission out, it would never be easier to replace the shift-lever seal on the back. I looked at it, and sure enough, there was indication of leakage. This is the kind of part that, when I order one, I’ll typically buy a few spares, so maybe I had one on hand. I rooted around in the garage, found one, and installed it.

No, I didn’t clean the back of the transmission. MWUHahahahahaha!

With the parts installed, it was time to do what I was dreading: deal again with my Rube Goldberg-like combination of the lift table, transmission jack, and plywood platform that I find necessary to remove and install a transmission on a mid-rise lift. Two weeks ago I wrote about how, during transmission removal, raising the lift to allow the transmission and jack to be rolled out from under the car brought the legs of the lift more vertical, which caused the hydraulic cylinders and the lift’s stop mechanism to contact the back of the wooden platform and tip it alarmingly. To ameliorate this problem, I cut notches in the platform so that when the lift was raised, its components would have clearance and not tip the platform.

As it turned out, the platform still tipped slightly, so I should’ve cut the notches deeper. I didn’t because, as you can see, they’re right where the front wheels of the transmission jack needs to roll in order to get the transmission all the way back.

The notches were effective, as far as they went.

No matter whether you have a full-height lift or work on the floor with the car on jack stands, or use a mid-rise lift and my odd jury-rigged configuration, reinstalling a transmission is a pain. With most other repairs, installation is easier than removal, since you’re no longer dealing with stuck fasteners, but with transmission installation, you have the triple whammy of fighting gravity; dealing with the fact that, once the transmission is removed, the engine tends to tip forward, making it difficult to get the back of the transmission high enough; and having to align the transmission very precisely so that the input shaft makes it past the Rubicon of the fingers on the clutch plate and into the splines on the clutch disc, and that the tip of the shaft goes into the center of the pilot bearing.

This is achieved by making small adjustments in the twist and height of the back of the transmission. You try to line up holes in the transmission bell housing with holes in the engine block using screwdrivers or 1/4″ ratchet extensions passed through both sets of holes, and sight around the bell housing to see if the transmission-to-engine gap is even. You swear and complain that something must be blocking it, and then you’ll push it slightly in some way, or reach in back and turn the output flange to rotate the splines on the input shaft, and suddenly it’ll THOCK itself into position—

At which point you weep with joy.

But this didn’t happen. In fact, I found my mind paraphrasing the 50-year-old Firesign Theater line, “It came out, it must go back in: Testicle’s Deviant to Fudd’s First Law of Motion.” To get the back of the engine as low as possible, I levered the front upward with a two-by-four between the oil pan and the sway bar, but while trying to align the transmission, it still hit the top of the tunnel.

I employed the usual entourage of screwdrivers and ratchet extensions to try to line up a hole on each side of the bell housing with its counterpart in the block, and I did feel the reassuring change when the transmission output flange would no longer turn freely, indicating that the splines on the clutch disc and the input shaft were engaging—but I couldn’t close the gap. In the past, I’ve employed sections of threaded rod with a nut on each end to pull the transmission in, but I couldn’t find them in the garage.

I resorted to using a ratchet strap between the transmission jack and the sway bar. This seemed like a great idea, and it did pull the transmission closer to the engine—until it had the unintended consequence of beginning to slide the transmission jack out from under the transmission. I didn’t think this was going to happen, because a little step on the bottom of the transmission was in front of the jack plate, but the tension of the ratchet strap dislodged it. I don’t think it was in danger of toppling off the jack, but it was now 5:30 p.m. on Christmas Eve, and it was clearly time to stop.

More than enough for tonight.

I hoped I’d end this piece with, “Zelda’s transmission is back in! It’s a Christmas miracle!” But instead I found myself in more of a Festivus mood. I had failed the Feats Of Strength, and I came back into the house and told Maire Anne of my disappointment, which qualified as the Airing Of Grievances.

All that was missing was the Festivus Pole. Maybe if I had one, I could use it to lever the front of the engine up higher.—Rob Siegel

Rob’s latest book, The Lotus Chronicles: One man’s sordid tale of passion and madness resurrecting a 40-year-dead Lotus Europa Twin Cam Special, is now available here on Amazon. Signed copies of this and his other books can be ordered directly from Rob here.