Greetings, all. I hope everyone had a good Thanksgiving.

Two weeks ago, I chastised people who automatically answer “It’s the bushings” to any question regarding clunks or rattles on a 2002. When folks say this, they usually mean the suspension bushings. So, in the piece, I listed all of a 2002’s suspension and steering bushings, their effects of being worn out, and what’s involved in replacing them. But I also noted that there are many other things that can cause noise over bumps, said that what you really want is a tight car, and that there are many things other than suspension bushings that contribute to (or subtract) from tightness.

So, the following week, I listed the bushings and other rubber items in the drivetrain and the exhaust, methodically walking from the front to the back of the car, and including things like engine mounts, the giubo, the center support bearing (none of which are bushings, but instead are “important rubber stuff that wears out”), the transmission support bushing, the bushings in the differential carrier that suspend the diff from the underbody of the car, and the exhaust hangers. As part of that vintage BMW bushing-related world tour, I began writing about the bushings in the shift platform, but quickly realized that that edged into the larger topic of the shift linkage, and decided that was better left for a piece all its own. Which is a professional way of saying that I strategically carved it out and left it in my writing refrigerator as something I knew I could tackle and digest in my post-Thanksgiving tryptophan-induced pie-bloated haze.

So let’s talk about shift linkage.

The shift linkage in a 2002 or other early 1970s BMW has four distinct components. There’s the shift lever (the thing you actually move with your hand). The lever is supported by the shift platform that’s bolted to the back of the transmission. There’s a linkage rod that connects the bottom of the shift lever to the selector rod that comes out of the back of the transmission. And there are a variety of, um, what should we call them? Oh, I know—bushings!—that connect the pieces to each other and to the transmission. (I’m being cute. Some of them actually are traditional bushings with a metal sleeve through the middle, but others are more like shims, sleeves, or adapters.) If a shifter has play, it’s usually possible to tell which of these pieces are bad from the direction of free motion in the shifter.

The older-style shift platform, lever, and linkage from a 2002.

Let’s start with the shift platform. It’s a stamped metal piece that’s folded over on the sides to create a stiff boxed section. At the front is a cup that holds the bottom of the shift lever (more specifically, it holds two nylon cups—I guess you could call them bushings—that, together with a retaining ring and a circlip, secure the ball at the bottom of the shift lever). At the back of the platform are two rectangular bushings that really are bushings—they’re rubber in a metal housing with a metal sleeve through the center, and they’re intended to isolate the shifter from drivetrain vibration. The metal sleeves are through-bolted into the platform from the top using 13mm bolts and nuts. The metal bodies of the bushings are bolted into the back of the transmission using 8-mm Allen-head bolts. The back of the platform is supported by a bracket that comes down at an angle and is bolted to the back of the transmission. It’s secured at the bottom by a 13-mm bolt and nut that goes through a rubber bushing that’s pressed into the bottom of the bracket, and secured and adjusted at the top by another 13-mm bolt and nut.

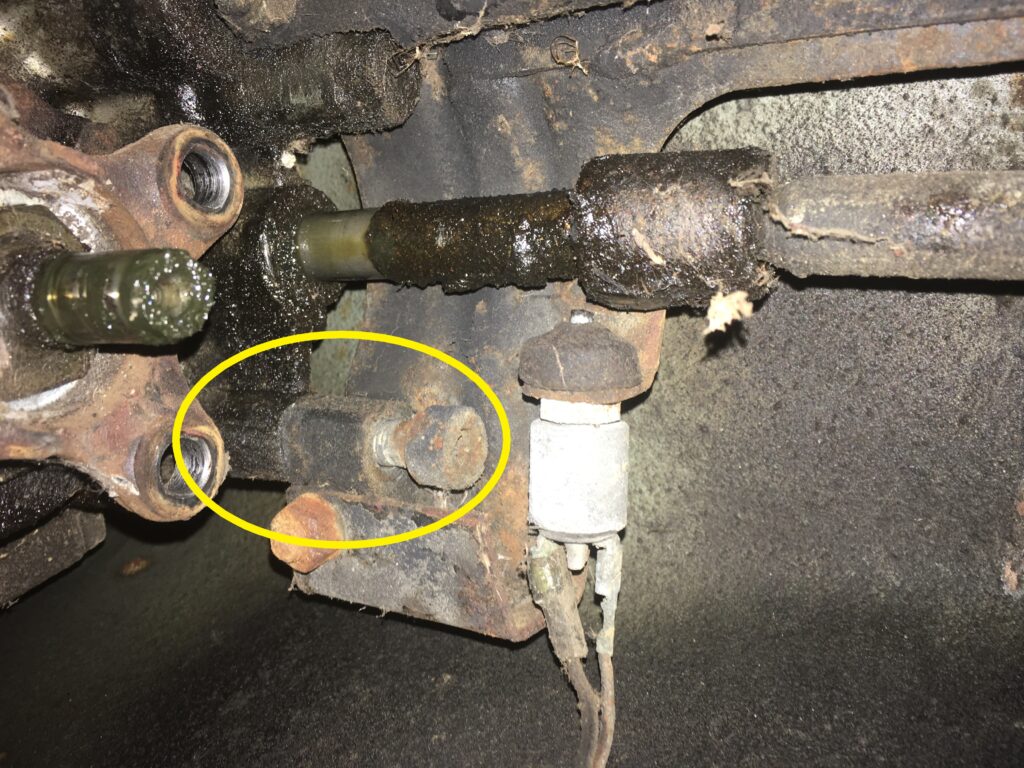

The front end of an old gnarly shift platform showing the two rectangular bushings and the 13-mm bolts and nuts holding them in place.

All of these fasteners can loosen, and all of these bushings can wear and cause play, though it’s typically the rectangular bushings on the back of the transmission that go bad, not the one on the bottom of the bracket. Looseness and/or wear of any of these parts translates into motion of the platform, which is a different problem than motion of the shift linkage. You can see the platform move if you lift up the shift boot, look where the shift lever goes into the platform’s cup, and move the shift lever from side to side, front and back, and up and down. If the platform motion is up and down, the back of the platform isn’t being held up against the underside of the transmission tunnel, which likely means that the bolt on the top of the angled bracket has loosened up or is absent. If, while driving, there’s a noise like a lathe cutting metal, either all the time or when shifting into 2nd or 4th, odds are very strong that that’s the problem. It’s utterly trivial to fix—just crawl under the car, push the back of the platform up, and tighten the nut and bolt at the top of the support bracket. (I have to say, there are few things more satisfying than having someone contact me and describe this classic “lathe in 2nd or 4th gear” symptom, and be able to tell them that they can solve it in 30 seconds with two 13-mm wrenches.)

An old-style shifter and forked linkage rod, and a transmission support bracket. It’s difficult to see, but the top (right side) of the support bracket is slotted for adjustment.

The attachment point of the bottom of the shifter support bracket. This is the end that has the bushing in it, but they rarely wear out.

If, however, the motion of the platform is side-to-side, either the rectangular platform bushings have gone bad, or one of the 8-mm Allen-head bolts has backed out. If all it is is a loose or missing bolt, you can sometimes tighten it or install a new one without a lot of effort (the one on the left is much easier to get at than the one on the right). However, if the platform bushings themselves are bad, because those 13-mm bolts come down from the top, you need to remove the platform to replace them, and that usually means undoing the center resonator from the headpipe, undoing the giubo and center support bearing, and dropping the front of the driveshaft. (Though I will admit to drilling a hole through the top of the transmission tunnel on a particularly ratty 2002 to get at the bolt and replace that one bushing without pulling the platform. Ah, youth.)

The driveshaft removed to access the 8-mm Allen-head bolt holding the right-size rectangular shift platform bushing. You can see that it had backed out. You can also see how the 13-mm nut holding the bushing to the platform is accessible, but there’s no way to withdraw the bolt from the top unless you remove the platform.

Let’s move on to the shift linkage. There’s a selector rod that protrudes from the back of the transmission. The end of it is round and has a vertical hole through it. The bottom of the shift lever has a much larger pinky-sized hole through it. It is the job of the shift linkage to connect these two together so motion of the shift lever results in motion of the selector rod with a minimum of side-to-side and fore-to-aft play.

The selector rod. Note the round end and the hole through it.

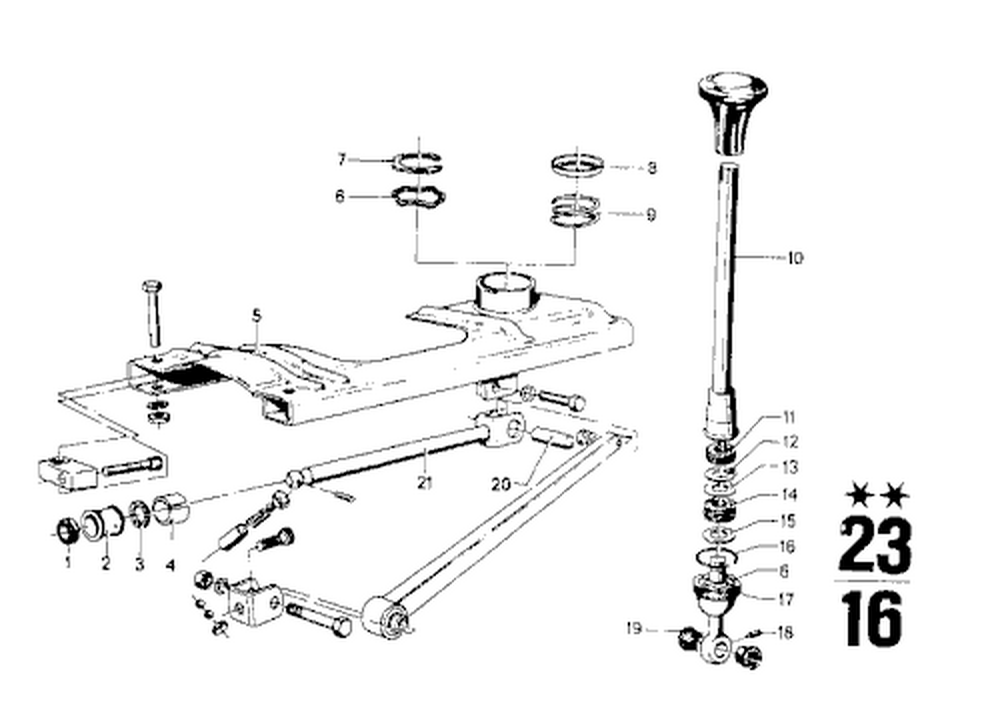

There are early and late-style shift linkages on a 2002. The early style uses a linkage rod where one end is forked, the two prongs of which straddle the bottom of the shift lever. A pinky-sized metal pin goes through the hole. It’s secured with a tiny Allen-head bolt (18 in the diagram below). Lateral play is taken up with a pair of quarter-sized nylon parts commonly called shifter “bushings” (19 in the diagram) but they’re really closer to shims with a ridge that snaps into the holes in the prongs of the linkage rod. The other end of the linkage rod is rounded exactly like the selector rod. They’re connected to each other via a “rod joint” that’s a cylinder that accepts the rounded ends of the selector rod and the linkage rod and secures them each with a small metal dowel that’s tapped in with a hammer.

Early-style shift linkage. Note the fork at the front of the linkage rod (21) and the thick pin that goes through it (20). Note also the little dowel shown going through the left end of the selector rod. It secures it to the rod joint (2). [Image by BMW.]

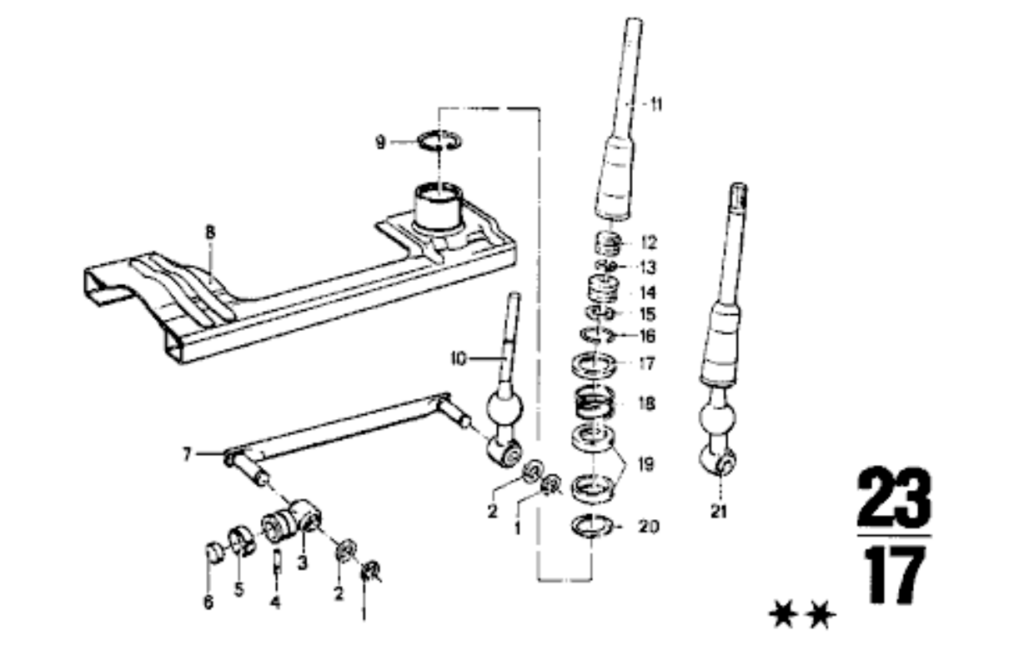

The later-style linkage. Note how the linkage rod (7) has two sections protruding from it at right angles, and how they go directly through the rod joint (2) and the bottom of the shift lever (10). [Image by BMW.]

This is actually off my 635CSi, not a 2002, but it shows an example of a later-style of linkage rod whose 90-degree protrusions pass directly through both the bottom of the shift lever and the end of the rod joint, with little nylon bushings taking up the slack, and square clips holding them in place.

With either the early or the late style linkage, if the shift platform isn’t moving but the shift lever has excessive side-to-side play, the problem could be coming from the shift-lever-to-linkage-rod connection, the linkage-rod-to-selector-rod connection, or both. If a car with the early-style linkage has a lot of side-to-side play, the quarter-sized nylon bushings on either side of the forked end of the linkage rod are the prime suspect (the later-style linkage rod usually provides tighter shifting on the back end than the early-style one). But in either case, the linkage-rod-to-selector-rod connection can also be a source of play. Sometimes replacing the rod joint and its little metal dowel or dowels solves it, but if the hole in the back of the selector rod itself has worn to the point that the dowel isn’t tight, you’ve got a problem. I’ve sometimes shimmed it by wrapping the dowel in a very thin piece of metal, but that only helps for a while.

Two new quarter-sized shift lever bushings at the end of an old-style linkage rod. The bottom of the shift lever will be slid between them, and the thick pin slid into place. Welding beads are visible on the rod and the shift platform because both have been shortened for a five-speed installation.

A few other things:

- The illustrations from the BMW parts manual show the shift lever as having a ton of components, but it’s unusual to need to disassemble it and replace any of them. The lower half with the ball and the upper half to which the shift knob attaches generally behave as a unit for the life of the car. Play is usually coming from somewhere else.

- Sometimes wear in the lower nylon cup under the shift ball can make it so that there’s a little bit of up-and-down play in the shift lever. This can manifest itself as buzzing. Adding a second wavy washer (shown as #6 in the diagram for the old-style linkage) usually solves the problem.

- There are a whole variety of aftermarket shift kits (shift levers, platforms, and linkages) that aim to tighten up the whole system as well as provide a shorter throw.

I think that’s it, linkage-wise and bushing-wise.

Gee, what do I have to write about next week? Oh. I know—every 10-mm nut and bolt on a 2002. No. Better still, something really useful—where the lost 10-mm sockets hide.—Rob Siegel

____________________________________

Rob’s newest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.