Last week I wrote about taking Hampton, my survivor ’73 2002, on a road trip to Vermont, but only after I pulled the cover off my ’73 3.0CSi (Rene) and saw that her inspection sticker had expired. I remembered that while preparing to drive Rene to the Vintage last spring, I found that there were visible rust holes on the muffler, and during the drive, those holes had yawned open considerably, making the car, shall we say, throaty.

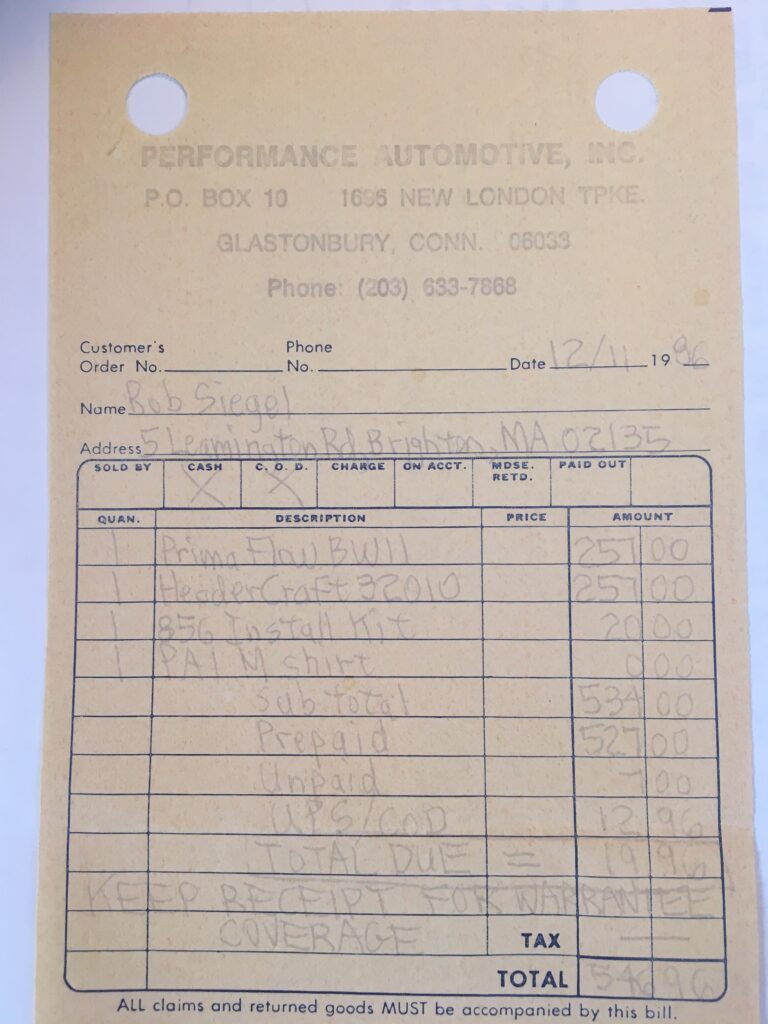

Since I’d installed the Prima Flow exhaust shortly after I’d bought the car in 1986, exhaust-longevity-wise, I didn’t have anything to complain about. But inspection-wise, it was roughly even odds that the car would fail. If this was Rene winking at her little sister Hampton and letting her go to the Vermont Fall Foliage Dance in her stead, so be it.

But I did want to get Rene legal.

What’s the world come to when you can only get 36 years out of an exhaust system?

The first task was to see exactly how bad the holes were, so I put Rene up on the mid-rise lift and had a look. I’d forgotten that the E9’s exhaust configuration is a bit unusual: The muffler isn’t like that of a 2002, or even a Bavaria. It’s long and sits crosswise in front of the gas tank and spare-tire well, with the resonator connection at a 90-degree angle

Weird, right? And no, I can’t recall what the origin was of that odd bracket on the right holding the muffler to the resonator.

Upon inspection, I saw that on the left side of the muffler was a big blob of exhaust putty that I must’ve shoveled into the rusting seam the last time it got loud, even though I had little recollection of having done so. To the right of it, you can see a rusty area with pinhole perforations.

The muffler wart on the left.

Looking further to the right, it got a lot worse. The center of the muffler was the source of most of the noise, with other weak areas spread out along the bottom. Fortunately, the rest of the exhaust—the resonator and the just-as-ancient and as long-out-of-production HeaderCraft headers—looked okay.

Yeah, that’s not good.

I’ve written quite a bit over the years about exhaust replacement. If you’re thrifty to the point of short-sightedness, like me, you might think that you can replace just the section that has the hole blown in it, and if you’re lucky, maybe you can. But there are two problems: The first is that if one section is rusty, the odds are that the others aren’t far behind it. The second is that even if you can separate the sections, the old and new pieces may not seal against each other. This doesn’t sound like it’s a big deal, but it can be maddening trying to mix and match new and old flares, flanges, and crush rings in a way that the thing doesn’t leak.

Yes, the other option to take the car to a custom exhaust shop and have them cut out the rusty section and bend-and-weld something in its place, but you face the same issue of them telling you that the rest of the exhaust is in a similar condition and having to make the choice to do it all.

A well-meaning friend sent me a link to an E9 stainless-steel exhaust system, but I wasn’t prepared to spend thousands of dollars. In my case, compounding the problem is the fact that the HeaderCraft headers have a bung welded in place for the oxygen sensor for the L-Jetronic injection that I retrofitted from an E12 528i, so even if I wanted to replace everything, I’m not certain that there’s a click-and-buy system.

Now, I make no apologies to anyone for how I choose to spend or save money. When I bought my Bavaria eight years ago and wanted to drive it to the Vintage just three weeks later, I faced a similar exhaust issue; the car had a three-finger-size hole in the muffler. I went to a big-box hardware store, bought a two-foot section of single-wall stove pipe, cut it to length to fit around the entire muffler, and held it in place with big hose clamps. It’s still there, and the exhaust is still quiet. Years later, I found a genuine BMW E3 muffler on eBay for a great price and bought it, but I’ve had no reason to install it.

The hole in the Bavaria’s muffler.

The stove pipe and hose clamps are still sealing it up eight years later.

Okay, then: As the World War II song said, “We did it before, we can do it again.”

I carefully measured Rene’s muffler and found that it’s five inches in diameter and 29 inches long. However, due to the 90-degree angle on the resonator port, the entire length can’t be neatly wrapped, like the Bavaria’s muffler, whose ports are on both ends. Fortunately, I didn’t see any rust holes near the resonator port. The wrapable length seemed to be almost exactly two feet, which is the length of a $10 section of stovepipe, but just to be on the safe side, I spent $18 for a five-foot section of six-inch diameter stove pipe and cut it to length. As it happened, I didn’t need it; two feet would’ve been fine.

Chim chiminey, chim chiminey, chim chim cher-ee… a Hack is as thrifty as thrifty can be….

I had to use a chisel to knock the wart of exhaust putty off the left side of the muffler to get the aluminum to lie flat. This made me see how close the rust was to the seam on the end of the muffler. I extended the aluminum over the seam and made a note to put multiple hose clamps around that area, and—

Hose clamps!

I suddenly realized that I was an idiot for not buying hose clamps while I was out. I was about to make another hardware-store run when I rummaged through the shelves in the garage and miraculously found the bag of leftover big hose clamps from when I’d performed this operation on the Bavaria eight years ago.

I had six clamps. On they went. But when I tightened down one of the two on the far left (the one directly over the leaky seam), I over-tightened it, and the worm gear slots stripped. I still need to buy a few more to clamp it redundantly.

Ta-DA!

But it’s done, and it’s quiet. I took the ever-lovely Rene down off the lift, patted myself on my back for my handiwork and my New England thriftiness, and did a cursory check of other inspection-related necessities before driving off to get a sticker…

Yup, eighteen bucks in chimney pipe and five hose clamps later, and we’re inspection-ready. We bad—oh, yeah.

…and found that the horn didn’t work. I had to laugh, as my reaction a few weeks ago when seeing Rene’s expired sticker—to simply take Hampton to Vermont rather than trying to get the car inspected—was more justified than I could’ve realized.

We’ll get to the horn next week, since it’s a perfect opportunity to walk through a classic electrical troubleshooting example.—Rob Siegel

____________________________________

Rob’s new book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.