Sigh. Today’s piece was supposed to be about doing, in the language of my people, a mitzvah (a good deed) by looking at 2002s for three people: two widows wrestling with selling their late husbands’ 2002s and a guy who wanted my advice on a tii, with all three errands centralized on the Massachusetts north shore. These visits went well, and I will devote a column to them at some point.

This column involves the problem that occurred on my drive home.

It was on a late Thursday. I was in my E39, the 2003 530i stick sport, the car I routinely describe as the best daily-driver BMW I’ve ever owned. I’d just ramped onto I-495. It was about 5:00 p.m., so I knew that as I headed south, I was certain to hit rush-hour traffic. I heard a short squeal, more like a chirp. Then the alternator light went on.

Crap.

Since the E39’s alternator and water pump are driven by the same serpentine belt, I watched the temperature like a hawk for any signs that the belt had been thrown and the water pump wasn’t turning. To my relief, the temperature needle stayed dead center.

However, you can’t just continue to drive a car when the alternator light is on. Well, you can, but there is a 100% probability that it will die, and soon. It’s just a question of when it happens and where you are. I had 50 miles of rush-hour driving ahead of me, so this wasn’t good. Fortunately, I saw a sign for a rest area. I pulled in to assess the car and my options.

Quick tutorial: The engine-off voltage from a fully-charged battery should be about 12.6 volts. With the engine running and the charging system (alternator and voltage regulator) working correctly, that voltage reading should rise to between 13.5 and 14.2 volts. So when the alternator craps out, the car’s electrical system is not seeing 13.5 to 14.2 volts but 12.6, and since there’s no longer anything keeping the battery charged, that voltages diminishes like water on dirt after rain.

Now, on a primitive car like a 2002, the only electrical load during daylight is from the coil firing the spark plugs, and I suspect that you can easily drive a hundred miles before the battery voltage drops so low that the ignition fails. But on a modern car with an ECU, multiple control modules, and electric fans and motors, the drain on the battery is much greater, and before long, the control modules flip out over the low voltage and begin to do very strange things. All the dashboard warning lights may come on. The car may start bucking. (Note that this may also happen if the alternator is working but the battery is deeply discharged from sitting and the car is jump-started.)

At some point, the car will die.

In addition to a car dying always being somewhere on the spectrum of inconvenient to dangerous, it’s more dangerous in a modern heavy car, because you lose the power steering and the power braking. This exact thing happened ten years ago to my wife when she was in New Hampshire with my previous E39, the 528i sport wagon. She was coming home from a camping trip with friends when the car wigged out, then died, causing her to have to wrestle the big, heavy car safely to the shoulder. She called AAA, and they jumped-started the car, but with the alternator not charging the battery, it simply died again a mile down the road.

She had it towed to a local repair shop. I drove up in the minivan, rescued her and her friends, and made a quick stop at the repair shop. I verified that with the engine running, the voltage at the battery was way below 12.6 volts, and authorized them to repair it. They replaced the alternator and charged me $600. Maire Anne and I had to drive up a week later to pick it up.

Back to the 530i: In the safety of the rest area, I popped the hood. The serpentine belt was still happily spinning all the accessories, so the alternator hadn’t seized. Since I’d just been looking at other cars, I had a multimeter with me (I try to always carry either a multimeter or one of those $8 cigarette-lighter plug-in voltmeters). I checked the voltage at the battery with the engine running: It read only 12.2 volts—not good. Not only was there no question that the alternator wasn’t charging the battery, the battery was already substantially discharged.

So, what to do? I had these options:

One: I could make a run for it, but with rush hour, it was probably at least an hour-and-a-half’s drive home. Even if there was zero traffic, getting the car 50 miles down the road with the voltage already down to 12.2 was not a good bet.

Two: I could find the nearest AutoZone or similar store, buy another battery, and jumper-cable them together to increase capacity. But an 850 CCA battery like the E39’s is at least $180, and even with the batteries doubled up, the odds of getting home were less than certain.

Three: I could see if the nearest AutoZone had an alternator for the car. But I didn’t have all of my tools with me. What’s more, I’d never replaced the alternator in a modern BMW with a serpentine belt. While I don’t know the details, I was certain that it’s more than the ten-minute job it is in a 2002. I assumed that I needed to take the serpentine belt off, which likely requires pulling the fan clutch, which likely requires lifting the fan shroud. Pros may be able to to his quickly, but I’m not.

Four: I could see if I could buy a voltage regulator and install it and hope that this solved the problem. The internal voltage regulator on the alternators on 1980s BMWs like E24s, E28s, and E30s is held in by two Phillips screws and can easily be swapped without removing the alternator. But, like alternator replacement, I’d never done this in an E39.

Five: I could do what most people would do: call AAA and have the car towed to a repair shop. Feh; that would cost me six hundred bucks, the way it did ten years ago with the wagon. And they’d probably use some awful remanufactured alternator.

Six: I could have the car towed home and fix it myself.

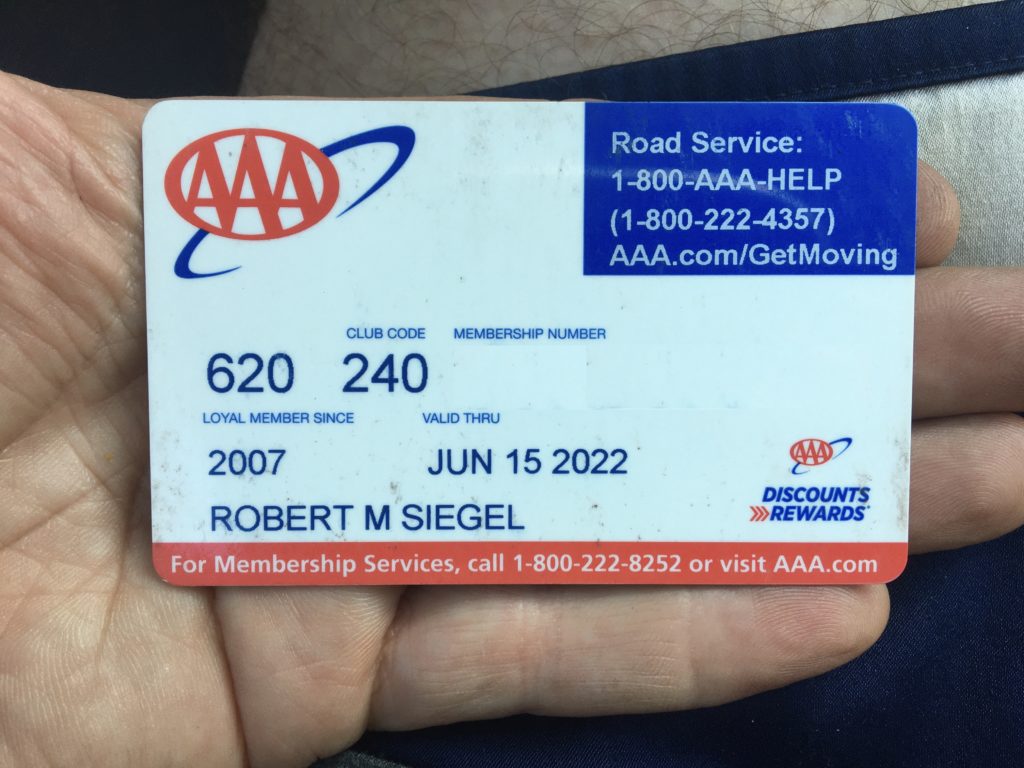

Of course I chose Door Number Six, but I really hated to pull the trigger on the tow home—not out of any shame, but just because I knew it would be a long wait. Preparing to call AAA, I pulled out my AAA card, and didn’t know whether to laugh or cry when I saw that it had expired the day before.

You have got to be kidding me.

I called Maire Anne and asked if I’d received a newer AAA card. Sure enough, she found an unopened envelope with a card whose expiration date was 2023. Unfortunately, I’d had this same thing happen last year when the E39’s fuel pump acted up and I needed a tow; when that happened, I called AAA and said I was looking right at my card with a valid date on it, and they said that they send out the new cards in advance of the renewal date, but if you haven’t renewed, the card isn’t active. They also said that yes, you can renew over the phone, but your towing benefit doesn’t kick in for 24 hours. I wound up waiting for the hot fuel pump to cool down, then nursed the car the five miles home on local roads.

Back to the present: Unsure of what my membership status was, I called AAA. Their automated system said that there were long wait times, but offered to send a text with a link to set up the tow. I stepped through it. To my surprise, they never asked for my card number; perhaps my cell number was already in their database and listed me as active. I don’t know. But at some point I received a call from a AAA agent saying that the wait time for a tow was likely three hours or more.

Damn.

With time to kill, I posted all of this to Facebook. FB friend Glenn Stephens chimed in, “Use Hagerty Drivers Club. Cheaper, better service, more responsive, and covers all your cars, including the modern ones.”

Hmm: I have Hagerty Drivers Club, but didn’t think about using it for one of the daily drivers. So I called Hagerty.

As many of you know, I write for Hagerty, doing for them much of what I do for BMW CCA but in a less BMW-centric fashion. The representative I spoke with confirmed that, yes, the Hagerty Drivers Club towing benefit does extend to my non-Hagerty-insured cars. Great, I thought. I gave her my current location and my home address.

Then came the surprise. The representative said that my Hagerty Drivers Club towing benefit was only twenty miles.

I was 50 miles from home. The tow charge would be $183. Further, the way that it worked was that she’d text me a link that I’d need to use to pay for the tow, and until that was done, it couldn’t be scheduled.

I briefly considered making a run for it and seeing how much closer (and thus cheaper) I could get before the Fiver died. However, although the traffic was likely subsiding, dusk was falling, and the idea of leaving my safe situation simply to save money seemed silly.

As they say, sometimes you just need to pay the man (or woman). I clicked the link and paid for the tow. The truck arrived in about an hour.

Whatever.

I’ve written many times about the age-old problem of being a do-it-yourselfer and getting parts in a timely fashion. That is, if you wait until you’ve taken things apart and fully diagnosed the problem, you’ve delayed the shipping of parts, whereas if you jump to what you think is the answer and order the parts you think you need, you could be wrong, or at least incomplete. There was no question that the alternator wasn’t charging the battery; the only real question was whether I could get by with just the voltage regulator, or whether I needed the alternator and regulator. The à la carte Bosch regulator is about $45. The new (not rebuilt) Bosch alternator and regulator together are about $290. I ordered the regulator, then went to the garage to begin removing the one from the E39. I figured that if I was wrong, I had other cars that could use the spare regulator.

If I had doubted my decision to have the car towed home instead of trying to find a voltage regulator and replacing it in the parking lot, the doubts vanished quickly as I got into the repair. The airbox has to come out, which is no big deal. And the power steering reservoir needs to be unbolted to increase the access; again, not a problem. But unlike the 1980s-era cars with a regulator that’s held on by two easily-accessible Phillips screws, the one on the E39’s alternator is hidden behind a plastic cover, and it’s a surprising pain to get it off.

The alternator has an evil, wicked rear cover.

I watched a video said that the cover is removed by undoing a big plug that holds the fat cable to the battery, then two 12-mm nuts on posts and a Phillips screw, but on my alternator, the nuts were 15-mm, and one of them was invisible because it was covered by a black plastic plug that looked like it was an integral part of the cover. I didn’t see this documented anywhere, and it took me nearly an hour to figure it out.

The plug wasn’t formed in a hex shape to have a socket fit over it and spin it off. I tried putting needle-nose Vise Grips on it, but rotating it didn’t remove it. I eventually pried it off with a screwdriver.

The video was correct in saying that reaching the Phillips screw down near the cover’s air duct requires a Phillips bit with a wrench on it rather than a screwdriver, because the coolant hose that runs just behind the cover blocks a traditional screwdriver. You can undo the coolant hose to improve clearance, but this is one of those wonderful snap-on hoses with plastic ends, metal clips, and O-rings, and my experience is that once you slide the connector off, it never seals again because you’ve disturbed the long-flattened O-ring.

The old wrench-on-the-Phillips-bit trick.

When I pulled the cover off, I found that it was packed with leaves.

And this was after most of the leaves had fallen out.

With the cover off, I could finally see the detachable voltage regulator, although it was difficult to discern the removable part from the other black plastic assembly that stays on the back of the alternator.

Exposed! The regulator is roughly the top part of the bunch of black plastic.

The video said that there were three Phillips screws holding on the regulator. I removed five, since it wasn’t clear to me which ones held on the regulator. Owing to the restricted clearance, I wasn’t able to use one of my standard screwdrivers, and had to use the Phillips bit and wrench that I’d employed with the screw-on cover.

With nineteen years of age and all that heat, these little buggers were tight, and one of them began to strip.

I had about fifteen stressful minutes and was nearly resigned to replacing the entire alternator when one final careful turn with all the pressure on the head of the screw I could muster managed to crack it loose. Whew!

The voltage regulator…

With the little two-screw regulators I’m used to, if you have a malfunctioning alternator, you hope that you pull out the regulator and see the brushes worn down, and often to uneven lengths. That was certainly the case here.

… and its errant brushes.

Unfortunately, when I looked at the copper slip rings in the alternator that the brushes run on, I could see that one of them clearly had a groove worn in it.

Hmm.

I nearly called FCP Euro, cancelled the order for the regulator, and ordered an alternator instead, but decided to give these copper slip rings a quick touch-up with Scotch-Brite, pop in the new regulator when it arrives, and see if that did the trick.

Taking the larger view for a moment, before the E39’s fuel pump acted up last summer, I was keenly aware that the car was under-maintained, and drove it knowing that a common fuel delivery, cooling, belt, or charging issue could sideline it at any moment. Thus I was hesitant to drive the car too far out of town. That was okay, however, because Maire Anne’s Honda Fit is a decade newer with a third the mileage. When the fuel pump malfunctioned, I used that as the trigger event to replace not only the fuel pump and filter, but also to perform a long-delayed cooling-system replacement. I replaced the radiator, expansion tank, thermostat, water pump, major hoses, and idler and tensioner pulleys, most of which were—egad!—original to the 200,000-mile car, and felt like I’d restored the invisible “reliability field” we like to think surrounds our cars.

Unfortunately, as I wrote about here, the new Graf water pump began leaking. It was a visceral example of how using new parts, even those regarded as good brands, is not a guarantee of reliability. I replaced the water pump, and again felt that I’d done what was necessary to drive the car without feeling like the other shoe was about to drop. Last year, I drove the car two New Jersey. Twice.

Now, with this charging-system failure and an inconvenient and not inexpensive tow, the reliability field has again been punctured. A friend of mine read about the E39 dying on Facebook and posted, “That’s why I drive newer cars.” She’s not wrong. Fortunately, I still work from home and have no real commute, and thus still feel like I’m able to get away with interesting inexpensive high-mileage vehicles. But maybe not forever. We shall see.—Rob Siegel

Rob’s new book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.