Near the end of the summer, I wrote about giving my daily-driver 2003 E39 530i stick sport some long-delayed preventive maintenance. The work was triggered by the car’s dying repeatedly on a hot day when the fuel tank was low; I used it as an opportunity to replace not only the fuel pump, but also most of the cooling system.

Okay, I lied. My first instinct was to replace only the pillowy-soft lower radiator hose. I ordered a CarQuest-labeled Gates hose on closeout from RockAuto for eleven bucks shipped, but then realized how foolish this was, reversed course, and ordered a cooling-system refresh package from FCP Euro.

When I tore the cooling system apart, I found that every component except the water pump was original to the car. Considering the failure rate of the E39’s legendary plastic-laden cooling system and the car’s 200,000 miles, that’s pretty astonishing. I installed everything, and with $500 of fresh decent-quality fuel-delivery and cooling-system parts, felt like the car’s dependability field had been regenerated.

About a month later I was surprised when a “low coolant” warning message came up on the E39’s instrument cluster. I checked and found that it was surprisingly low—it took nearly a quart. I didn’t really think that much of it, though, since I didn’t smell coolant and saw no evidence of it leaking under the car. I chalked it up to perhaps my not having bled the air out completely. I filled the system, bled it again, and continued to use the car as one does with a rejuvenated daily driver.

Then, a few weeks ago, I wrote about positioning the cars for the winter, putting the ones I thought I’d be working on within the next few months in the garage and banishing the others to outlying storage. The ones that got to stay were Louie the tii, Rene the E9, and the Lotus. This fills the garage, which means that any maintenance on a daily driver requires kicking a vintage car out into the cold.

Within days, the roads got salted and the first snow fell. So of course this was the moment that the E39 chose to get needy.

Like the Christmas ghosts from the Dickens novel, the problems came in three forms. The most minor was the windshield-washer pump’s giving up the ghost (heh) just as the windshield was getting coated with salt. The second was a pair of longstanding problems that were exacerbated by cold weather: a check-engine light due to an intermittent misfire from a stick coil and a groaning power-steering pump (along with a steering wheel that requires a lot of upper body strength for the first few turns in the morning).

It was the third problem that was pretty serious.

I was driving to give a talk at the Larz Anderson Auto Museum in Brookline—my first public-speaking engagement in nearly two years—when the “low coolant” warning message again elbowed its way onto the E39’s instrument cluster. Fortunately, the coolant temperature was still in the middle of the gauge, and I only had two more miles to drive. I stopped and didn’t see or smell any coolant, so I continued, fully recognizing the irony that one of the topics of my talk was “The Big Seven” things likely to strand a car: One of them is, of course, cooling-system issues.

The museum is less than five miles from my house, so I counted on the double-warning (the relatively early warning of the low coolant level plus the temperature gauge) and made it home without incident.

I put an inexpensive aftermarket washer pump on order with Amazon for next-day delivery. I knew that I had a stick coil that I’d bought when the misfire code on #3 began popping up last winter; I just had to find it in my garage.

The next morning I kicked the Lotus out into the cold and brought the now-problem-child E39 into the garage. I dealt with the easy issues first: I rummaged about in the garage and found the spare Bosch stick coil that I’d bought last winter, and laughed when, right beside it, I found a never-installed washer pump that I bought years ago for my E39 wagon.

Okay, so now I had two. No big deal.

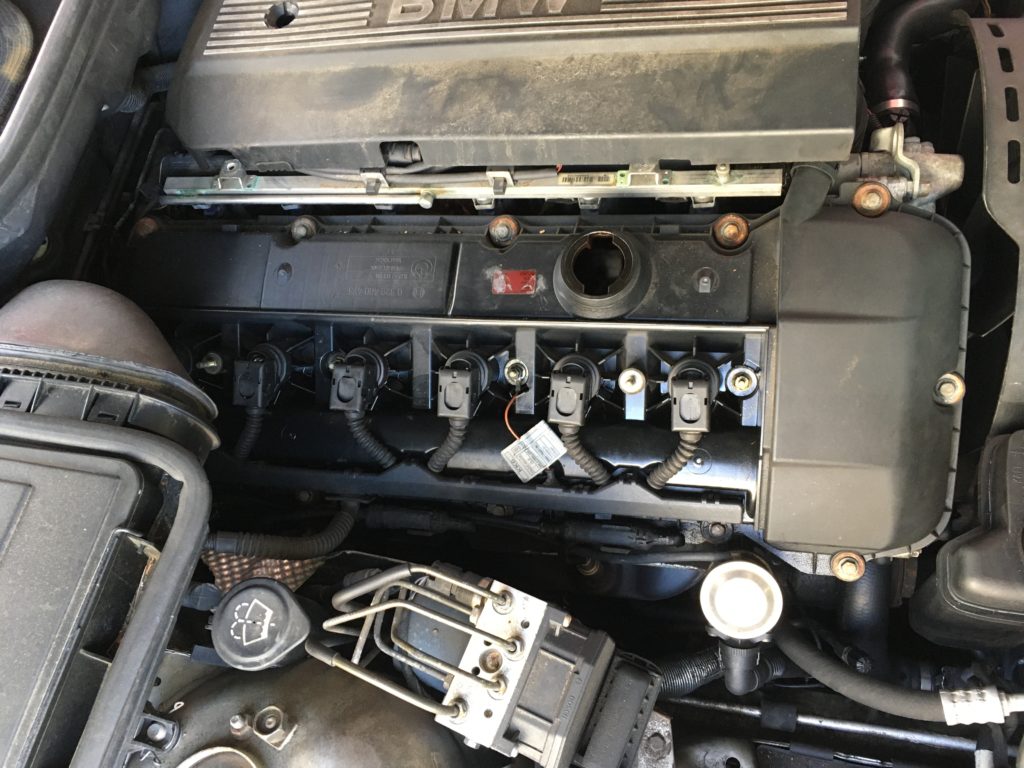

I’ve long thought that a bad stick coil is the best application of the onboard diagnostics (OBD-II)/check-engine-light (CEL) system every car has had since 1996. Plug any $20 code reader into the car’s OBD-II port, and instead of the message being something dense and impenetrable like “P0442 Evaporative Emission Control System Leak Detected (Small Leak),” it unambiguously tells you, “Misfire Cylinder 2,” or whichever one is misbehaving. You check that plug, see that it’s fine, replace that stick coil, clear the code, boom, done. I verified that it was indeed #3 that was throwing the code, as it had last winter, popped the false valve cover off, pulled the stick coil, and installed the new one. (I can continue to hate OBD-II for the other minor codes it throws, but for this, it’s actually very handy.)

Swapping stick coils is a quick and easy repair.

Next, the washer pump. As with any modern car, the washer tank and pump on an E39 aren’t easily accessible at the top of the engine compartment, as they are on a vintage car such as a 2002. Instead, they’re hidden in a crevice that otherwise would be wasted space. On an E39, they’re behind the passenger-side fender liner.

I jacked up the front of the car and set it on stands so that I could pull the wheel off to get clearance. After removing a bunch of screws with 8-mm heads and a few clips, I pulled enough of the fender liner away to be able to access the tank and the pump. I used a multimeter to verify that the pump actually was getting voltage when I pulled the washer stalk in, then swapped the new pump in before all the just-filled washer fluid ran out on the garage floor.

The washer tank and pump are definitely well hidden.

It was time to address the coolant-loss issue. While the E39 was up on stands, I crawled under it, looked carefully at the under-cover, and saw a wet spot around the hole at the low point.

Okay…

I pulled the cover off and saw unmistakable evidence of coolant leaking. So much for my, “It just wasn’t completely bled” theory.

Denial ain’t just a river in Egypt.

Figuring that I was in for a longer haul finding the source of the coolant leak, I took the E39 down off the stands and swapped positions with the E9 on the mid-rise lift. This let me get under the nose of the E39 more comfortably, as well as lower it easily to work under the hood.

I WISH the garage was bigger on the inside. That would solve so many of my problems.

I undid the interlocking puzzle that comprises the fan shroud, and the myriad of hoses and the expansion tank clipped to it, and lifted it and the fan and clutch out, leaving everything else intact. I pulled off the serpentine belt and water-pump pulley, pressurized the system with my Stant pressure tester and its BMW expansion-tank adapter, and watched.

The pressure tester is a very handy tool to have.

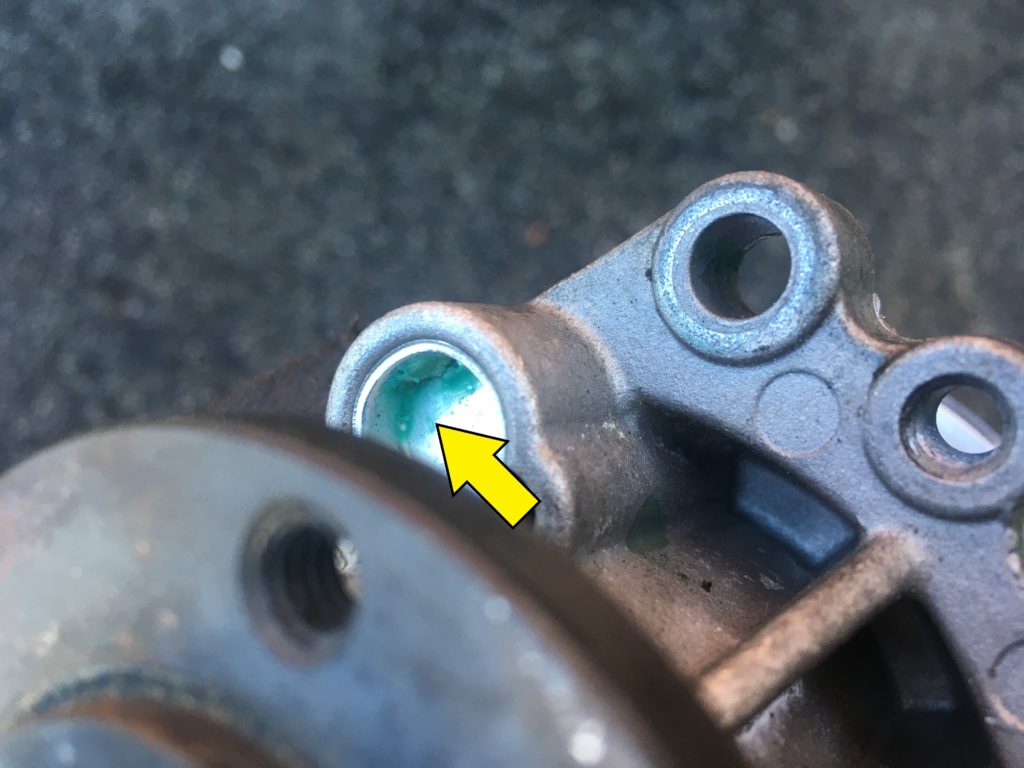

Eventually I saw small rivulets of coolant running down the front of the block—but the source was difficult to determine. By using a mirror as well as feeling with my fingers, I determined that the leak was coming from the Hepu water pump that I installed in August. I pulled it out, and sure enough, there was congealed coolant in the pressed-in cap below the weep hole. Remembering the first “low coolant” warning not long after I’d installed it, I realized that it was likely that it had been leaking since Day One.

You bad boy.

I posted the episode to my Facebook page, and opinions flooded in (appropriate, since—never mind). The genuine BMW water pump and its OEM counterpart from Saleri have a composite resin (i.e. plastic) impeller. For decades, the mantra has been to replace it with a pump like the Hepu, which uses a metal impeller. However, to my surprise, some folks whose opinions I respect—most notably professional mechanic Tom Jones—still recommended the Saleri with its resin impeller.

I contacted FCP Euro. They quoted the failure rate of the Hepu as about 30 returns for about 5,000 sold. The Saleri’s quoted failure rate was very slightly lower, but probably statistically identical. Still, I swapped the Hepu for the Saleri. FCP had no issue replacing the pump under their lifetime-warranty policy, although the brand swap required an additional form.

When I buttoned things up, there was some amount of shoving things around to get the tabs on the fan shroud to sit properly in the slots on the radiator, even though I hadn’t pulled the radiator. I refilled the cooling system and saw coolant streaming—not dripping, mind you, streaming—from the snap-on connection between the bottom of the Nissans replacement radiator and the Rein replacement lower hose.

I gently tugged the hose in one direction and made the leak stop, then moved it in another direction and made it leak again. What, I thought—is one of these five-month-old plastic connections cracked already? Hokum smokum! I drained the coolant, pulled the connection apart, and inspected both sides. Nothing appeared cracked. The O-ring inside the plastic hose end appeared flattened, but that’s not unexpected.

What a pain. There didn’t really seem to be much choice except to order another lower hose. At least FCP Euro would replace that under warranty, too.

Then I remembered that I still had that eleven-dollar CarQuest/Gates hose that I’d ordered from RockAuto before I got religious and “did it right.” I found it, gleefully ran my index finger over its fat, plump, unflattened O-ring, snapped the hose into place, and refilled the system.

Leak gone.

I could launch into a lengthy diatribe about how the cooling system in this car had been working perfectly; how, by prophylactically replacing parts like you’re supposed to, I’d caused it to leak from not one but two places; and how it’s getting more and more difficult to maintain these cars at some reasonably knowable point of reliability. But it really doesn’t matter; that invisible dependability field I’d constructed around the E39 is now officially gone.

Oh, and the groaning power-steering pump? I didn’t touch it. I mean, I’m not a fool.—Rob Siegel

Rob’s new book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here. Plus, five of Rob’s books are on sale for the holidays (cheaper from him than through Amazon).