Efforts concentrated on 3D printing, or additive manufacturing, as BMW refers to it, are continuing to advance towards an eventual future which will see components produced using the manufacturing method as part of regular series production. Progress over the years has been gradual but steady, with development coming in the form of the occasional one-off example, like the brake calipers of the M850i Night Sky, for example, or more recently, the cylinder head core of the S58 M inline-six engine. In June of this year, BMW opened its Additive Manufacturing Campus in Oberschleissheim, Germany, just north of Munich.

This year, the use of 3D printing has been expanded, with the BMW Group using the method to produce small quantities of parts for Rolls-Royce models. We’ve not yet arrived at the point at which anything you will actually see, touch, or interact with on a vehicle will be 3D printed, but the time will soon be upon us. Right now, the BMW Group is producing polymer body components at its Additive Manufacturing Campus for Rolls-Royce vehicles, more specifically parts which join body panels to form what’s referred to as the passenger cell. They take less time to produce, their construction is incredibly rigid, and the quality resultant from the new manufacturing process is the same as traditional methods.

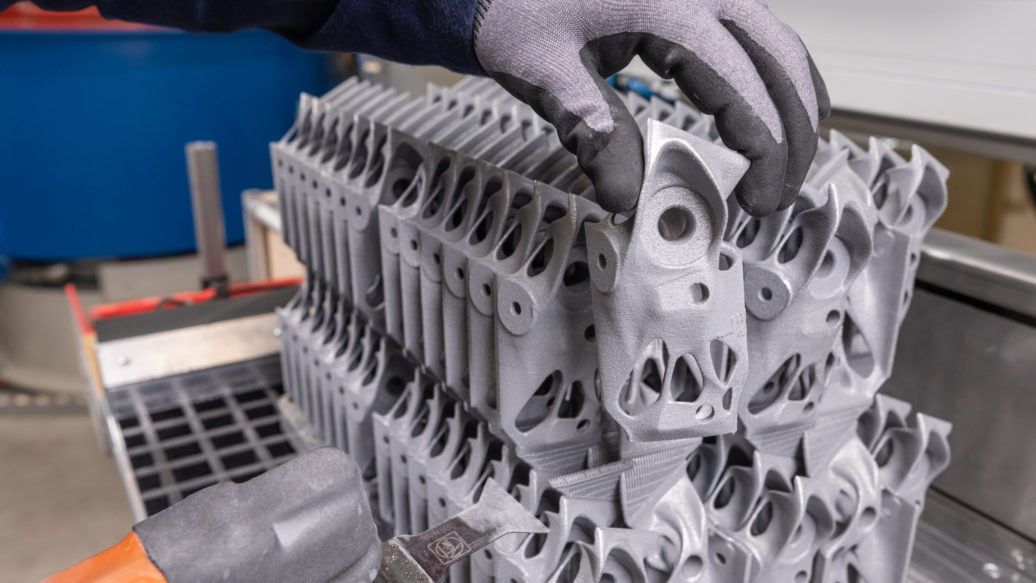

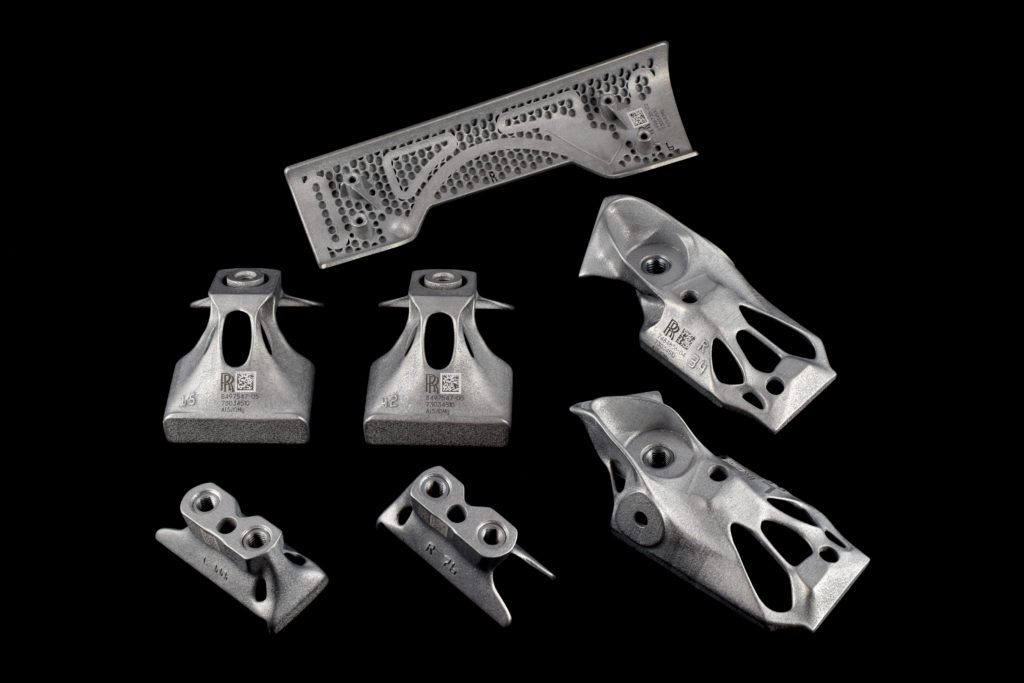

BMW’s Additive Manufacturing Campus is also producing parts using multi-jet fusion and selective laser sintering, while at BMW Group Plant Landshut, the automaker’s emissions-neutral foundry, metal parts are being manufactured by way of laser beam melting. In addition to speeding up the development process thanks to benefits in generative prototyping, 3D-printed components can also be installed in vehicles in an almost completely automated way. For some parts, an entire complex global supply chain can be reduced down to a few core elements.

Artificial Intelligence plays a role too, with software that has been developed to screen components to determine their eligibility for 3D printing using a special, “machine language.” It’s not all about manufacturing, economies of scale, and costs, however, as BMW enthusiasts will be please to know that, just as promised, parts produced using additive manufacturing or 3D printing typically weigh about half as much as their traditional counterparts.—Alex Tock

[Photos courtesy BMW AG.]