The final book I wrote while I worked at Bentley Publishers was Mechanical Ignition Handbook: The Hack Mechanic Guide To Vintage Ignition Systems. It sort of slipped under the radar, as it was released after I left Bentley. Coincidentally, its release date was within a couple of weeks of my own self-published Ran When Parked, and the latter eclipsed the former.

To be clear, I have no financial stake at all in the book, since I wrote it as a Bentley employee and thus get no royalties from its sale; but while writing it, I did augment my knowledge of points-and-distributor-based ignition. Because I get asked the same ignition questions over and over, I thought I’d take a moment and answer the most common ones.

What do y0u mean by “mechanical ignition”?

I’m referring to the ignition system on most pre-late-’70s vintage cars with three ignition-related functions that occur mechanically, whereas on later cars, some or all of them occur electronically. These three functions are:

- Contact points inside the distributor open and close, which trigger the ignition coil to generate high voltage.

- The distributor distributes that high voltage to each spark plug via a rotor that spins around inside the distributor cap.

- The distributor advances the spark via weights, springs, and moving plates inside the body of the distributor.

How does it work?

Spark—or rather the high voltage that generates spark—is created inside the ignition coil, but components inside distributor act as the triggering mechanism for that high voltage, releasing it at the proper time. The main shaft inside the distributor has cam lobes on it, one for each cylinder, and those lobes force the points open momentarily as the shaft spins around. It is this opening of the points that toggles the coil between its low-voltage (“primary”) and high-voltage (“secondary”) settings. The condenser on the side of the distributor has several functions, but the simplest one is that it prevents spark from arcing across the points as they open and close.

The high voltage then travels out the fat wire from the center of the coil into the distributor. As its internal rotor rotates, it touches a terminal for the wire to each spark plug, thereby distributing high voltage to each of the spark plugs. The high voltage jumps the gap in each plug to ground, and—kaBLAM!—ignites the fuel/air mixture in each cylinder.

(By the way, we have Charles F. Kettering to thank for all of this. He designed the ubiquitous ignition we know and sometimes love. It was first installed on a 1910 Cadillac, and continued, with very few changes, for nearly 70 years. Fun fact: Mr. Kettering then quit his job at National Cash Register and formed a new company called Dayton Electronics Laboratories Corporation, whose initials we recognize as Delco.)

There are many ignition-description videos on Youtube, but this one gives the best overview of how the system actually works, including a great level of detail on how the primary and secondary windings inside the coil actually create the high voltage.

And with that, let’s answer the most common questions I get, framed within the context of how these three distributor functions changed over the years, and whether and how those improvements can be retrofitted into a vintage car.

Can I replace mechanical triggering with electronic triggering (Pertronix and the like)?

The first improvement, so-called electronic or “breakerless” ignition, came in the mid-to-late 1970s. One of the problems with points is that eventually the timing “wears,” because the point gap gradually gets smaller. This happens for two reasons. The first is that the making and breaking of the electrical connection across the points causes them to develop pits on one side and mounds on the other, effectively making the point gap smaller. The other is that the nylon block that rides on the distributor’s cam lobes gets worn down, causing the points not to open up as far. This is why checking and resetting the point gap (or, more accurately, setting the “dwell,” which is the angle out of a 360-degree engine rotation during which the points are closed) is part of the traditional tune-up on a vintage car.

As the point gap closes, it creates two issues. The first is that the dwell itself goes out of spec. Eventually, the points don’t open far enough to trigger the secondary circuit and fire the coil, and the car dies by the side of the road. But the second issue is that the shrinking dwell retards the ignition timing, affecting performance and making the engine run hotter. This is a significant effect. Depending on how you do the calculation, it’s either one or two degrees of advance per degree of dwell. Take the best case; say it’s one degree. The dwell spec on a 2002 is 59 to 65 degrees. Say you tune the car, set the dwell at 60 degrees, and time the car with a timing light. Let’s say that, over time, the points close up from natural use and wear so that the next time you measure the dwell, it’s at 65 degrees. That is expected to retard the timing by five degrees from when it was last set. That’s a lot.

The classic arrangement of points with the nylon block riding on the cam lobe. The condenser is at upper left.

“Breakerless” ignition replaces the points (and the condenser) with something non-mechanical that doesn’t wear, and thus shouldn’t change over time. Some early breakerless systems used a light passing through rotating slits, but most used some sort of magnetic sensor, either a variable reluctor system with a star-shaped wheel, or a Hall Effect system with a rotating magnetic ring on the shaft.

In BMWs, I believe that electronic ignition came in the late 1970s with a mid-series refresh. That is, an E12 530i still had points, but an E12 528i had an electronic ignition system with a reluctor wheel inside and a big electronic box on the firewall.

The Pertronix electronic triggering system that’s often retrofitted into vintage cars is a much smaller Hall Effect system with a magnetic sleeve on the shaft and a tiny box that’s bolted in place of the points.

This 40-year-old factory electronic triggering system from the E12 has been retrofitted into my 3.0CSi.

The advantages of retrofitting something like a Pertronix system is that by eliminating the points, you’re getting rid of the wear of the nylon block and the pitting of the points. This solves both the problem of the changing point gap influencing timing, as well as the problem of the car dying because the points have gradually closed up entirely (or because the nylon block has suddenly snapped off). And by eliminating the condenser, you’re solving another problem: the fact that most modern condensers are absolute garbage (I’ve had new condensers in BMW boxes fail in five miles). Together, that means that your vintage car is less likely to die, say, while crossing the George Washington Bridge in New York because the points have closed up. Personally, I can do without that kind of stress in my life.

The Pertronix-like Hotspark installed is in one of my 2002s.

The disadvantage, according to some, is that you now have a little black box that’s difficult to troubleshoot and can fail at any moment. I don’t subscribe to that view; I’ve only had them fail when I’ve wired them incorrectly. But, yes, I do have points and a condenser in the trunk just in case. Given the choice between running on points/condenser and Pertronix for long road trips, I’d take electronic triggering every day of the week and twice on Sunday; I have them in all my vintage cars except the Bavaria, which for some reason did not run right on Pertronix—I was leaving for the Vintage the next day, and I never circled back to figure out why.

Note that when you install a Pertronix or similar system, you’re getting rid of the points and condenser, but the distributor still has mechanical spark advance, and is still mechanically distributing the spark to each cylinder.

Will electronic triggering improve performance?

No, not really. Some folks report that their cars idle smoother with electronic triggering installed. That may be, but in general, electronic triggering is a maintenance-and-reliability improvement. You shouldn’t expect a performance improvement out of it.

Can I retrofit electronic advance (123 Ignition)?

Over time, the performance of weight-and-spring-based advance systems in conventional distributors degrades. Sometimes, due to lack of lubrication, the weights, springs, and plates will stick at the pivot points. Sometimes the advance won’t move, then will jump at certain engine speeds. Sometimes it’s just stuck. It’s not at all uncommon to put a timing light on a vintage car, shine it at a timing mark, rev up the engine, and not see the mark move, indicating that the distributor isn’t advancing at all.

Electronic advance was incorporated into new BMWs as part of the first generation of Motronics that came in in the early 1980s. You can tell by those weird-looking oval distributor caps that are on the front of M20 engines in E30s and M30 engines starting with the E28 533i. Although the cap is oddly-shaped, underneath it is a conventional rotor spun by the end of the camshaft, distributing the spark to each of the plug wires. However, there is no “distributor advance” (no cylinder with weights and springs) because spark advance is handled electronically by the vehicle’s electronic control unit (ECU). Note that when you get into E36-era cars, this configuration is replaced with “coil-on-plug” ignitions where each spark plug has a coil directly above it. That’s why, in later cars, you don’t see a centralized ignition coil and a bundle of plug wires.

The non-round distributor cap on a Motronic M30 engine. There’s no “distributor advance,” but there’s still a rotor underneath the cap, distributing the spark from one coil to the individual spark plugs.

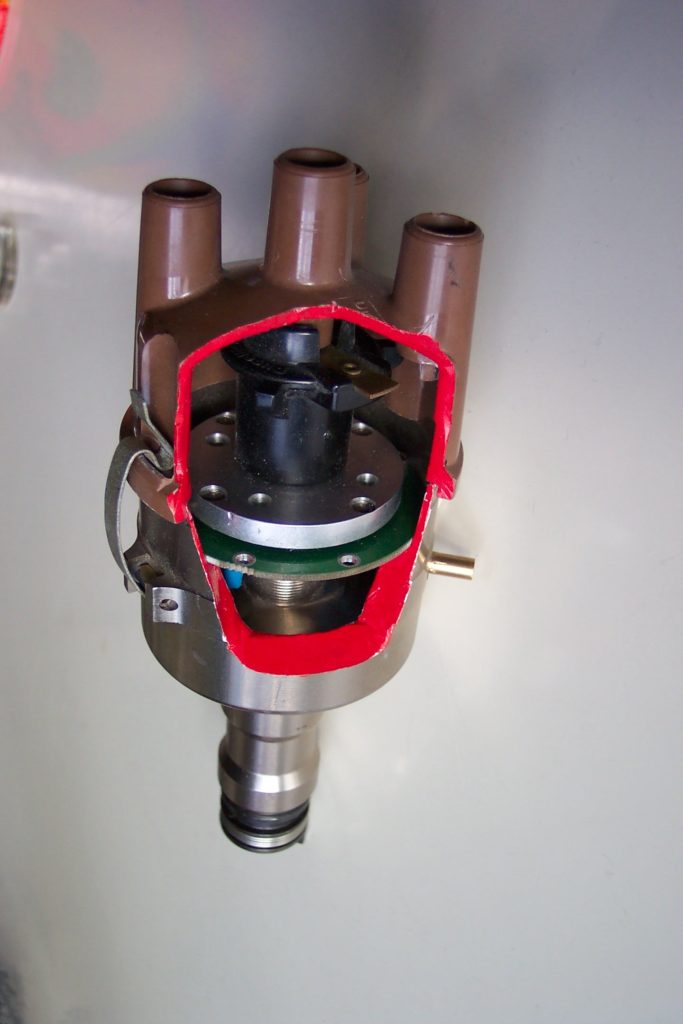

If you want to retrofit electronic spark-advance capability into a vintage car, look at the distributors manufactured by 123 Ignition. They’ve become popular in vintage-BMW circles, as these eliminate mechanical spark advance. (Well, to be clear, they eliminate both mechanical triggering and mechanical spark advance). They look like conventional distributors, but inside, instead of springs and weights, there are electronics that control how much the ignition timing is advanced as a function of engine rpm. The least-expensive versions of the 123 come with stored timing curves, but there are USB-programmable and Bluetooth-programmable models. You then can spend endless nights on bmw2002faq.com reading what curve is a good starting point for your engine with the 10:1 pistons, Schrick 292-degree cam, and dual Weber 40DCOEs, and then uploading that curve and tweaking it.

The internals of a 123 Ignition distributor: no weights and springs. [Photo courtesy 123 Ignition.]

Will electronic advance improve performance?

Yes, it should. Note that when you adjust the timing on a conventional distributor, rotating the body of the distributor to advance or retard the timing, all you’re doing is sliding the entire timing curve to the left or right. In contrast, on a programmable 123, you can dial in more advance within a specific rpm range, so unlike installing Pertronix or other electronic triggering, a properly-tuned 123 should be a performance improvement. People report that once tweaked, their engines run better due to both the elimination of timing bounce and jitter from the springs and an advance curve that’s actually proper for their engine.

To be clear, if you install a Petronix in your BMW 2002, you have electronic triggering but still have mechanical advance. But if you install a 123, you have both electronic triggering and electronic advance. Got it?

What the hell is that ballast resistor for, and do I need it?

I get this one a lot. The ballast resistor is designed to limit the amount of current drawn by the coil while the engine is running, but to lift that restriction and allow for a stronger spark when the engine is started. That’s it—that’s all it is. It’s not difficult. (For details on that wiring, see my post on bmw2002faq.com here.) And yet the confusion over them never ends.

Ballast resistor (white) with original Bosch Black coil.

The original coils used on most 2002s, E9s, and Bavarias were Bosch Blacks that had about 2 ohms of resistance as measured between the “15” or “+” terminal and the “1” or “-” terminal. They were used with a white ceramic ballast resistor that had about 1 ohm of resistance, for a total series resistance of about 3 ohms. Part of the confusion is that at some point in the 1970s, Bosch began manufacturing their blue coils and marketing them as a performance improvement. They really weren’t, but with a 3-ohm internal resistance, they could be run without a ballast resistor. People didn’t understand the function of the resistor, and this was simpler, so simpler was better.

To make matters even more confusing, later 2002s (’75 and ’76, I believe) have a “resistor wire” instead of a plainly-visible ballast resistor, making it unclear whether or not there is additional series resistance.

Then, at some point, Bosch began selling the red coils paired with red ballast resistors. As they did with the blue coils, they marketed this as a performance set. I’ve measured these at about 1.7 ohms each, for a total series resistance of 3.4 ohms.

These numbers are important, because if you read the instructions on a Pertronix or similar triggering module, they warn that they need to be connected to coils with at least three ohms of resistance. If the resistance is lower, too much current can flow from the coil through the triggering electronics, damaging them. I can attest to this; I burned up a Pertronix by running it connected to an original Bosch Black coil from which someone had disconnected the original ballast resistor.

To summarize:

- If you have, or are installing, an electronic triggering module, you need to be certain about the coil/ballast resistance. If you have a Bosch Blue coil, you’re fine, but for any other coil, measure the resistance from the input to the ballast resistor to the “1” or “-” side of the coil and make sure it’s at least 3 ohms. If it’s not a Blue coil, and you don’t see a ballast resistor, and it’s a post-’74 car, read up on where the “resistor wire” is and verify that it’s still there.

- If you’re not using a Pertronix or similar triggering module, for earlier non-resistor-wire cars, if it has a Black or Red coil that’s meant to be run with a ballast resistor and the resistor isn’t there, it’ll probably cause the points to pit faster, but it’s not critical, as it is with a Pertronix.

If there’s no spark, which ignition component do you suspect first?

I always check for spark by pulling the center wire out of the distributor, holding it near ground, and cranking the engine, as this eliminates the distributor cap and rotor from the equation. If there’s no spark, check that the coil is receiving 12 volts at the “15” or “+” terminal when the ignition is cracked to ignition, and that the spade connectors on that and the “1” or “-” terminal are firmly pushed on.

If there’s power but no spark, suspect the points first. Pull off the distributor cap and have someone crank the engine over while you watch the points. You should be able to see them open and close and see a faint arcing across them. Often, if there’s no arc, they barely move. Gap them to 0.016 inches (the old trick of using a matchbook gets you close).

If there’s still no spark, try the condenser next. Sometimes all that’s wrong is that the screw holding it to the distributor is loose; that’s the ground path, so it has to be snug. If you have an old “known-good” one, try swapping it.

It certainly is possible that the coil is bad, but it’s far less likely than the wiring, points, or condenser.

The best ignition-troubleshooting lesson EVER

I’ve probably told this story here before, but a few years back I had a vexing ignition problem on my 2002tii. Despite brand-new cap, rotor, points, and condenser, it barely ran. I couldn’t figure it out. My friend (and a professional) Lindsey Brown came over. He had a distributor. “This is known good,” he said. “I just pulled it out of my 2002. Let’s put it in.”

“How can you say,” I asked, “that yours is known-good and mine isn’t? I have brand-new parts in mine, and the whole distributor was just rebuilt.”

Lindsey shut me down. “ARE YOU HAVING A PROBLEM OR AREN’T YOU?”

“Well, yes,” I sheepishly admitted.

We swapped in his dizzy, with me mumbling, “something something known good my butt something something.”

The car started right up. My jaw hung open.

“Now,” said Lindsey,”let’s swap parts from your dizzy into mine until it fails.”

It was the condenser.

I’ve never forgotten this lesson, and I never will.

May your ignition always spark, and your points never close up on the George Washington Bridge.—Rob Siegel

Rob’s new book, Resurrecting Bertha: Buying Back Our Wedding Car After 26 Years In Storage, is available on Amazon here. His other books, including his recent Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, are available here on Amazon. Or you can order personally-inscribed copies of all of his books through Rob’s website: www.robsiegel.com.