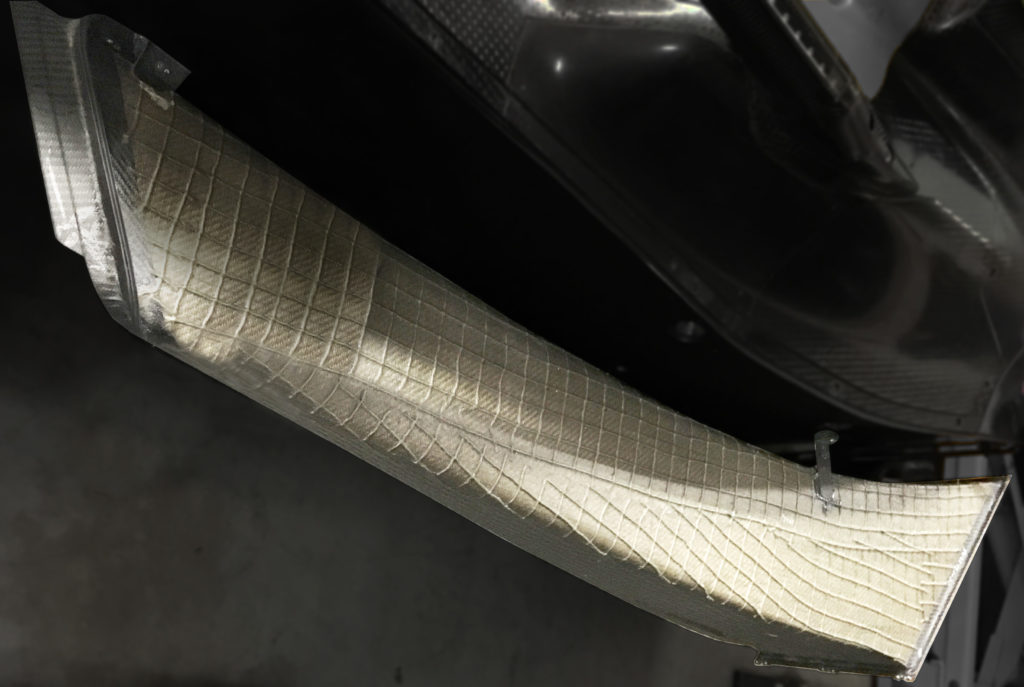

From the start of its involvement in Formula E, BMW has focused on the series as a technical development lab. One cutting-edge innovation in its Season 5 Formula E car, the iFE.20, is the use of a flax cooling shaft. BMW says that it represents the first use of a textile fiber part in a BMW race car fielded by a works team.

The flax cooling shaft is a renewable textile fiber race car part.

BMW motorsport director Jens Marquardt says, “The flax cooling shaft that we use in the BMW iFE.20 is further proof of the hugely important role of BMW i Motorsport as a tech lab for the BMW Group. We are consistently using Formula E as an innovative platform for series development—in this instance for testing flax in extreme weather conditions. What’s particularly remarkable is the fact that in some areas this renewable material even has advantages over materials established in racing, such as carbon. Our ambition is to always use the best suited material for each part.”

In its release on the cooling shaft BMW says “Compared with carbon, flax has greater absorption and greater impact resistance, which can be advantageous on the street circuits with their bumps and crash barriers, on which Formula E takes place. The same is true of contact with other cars during races.

“The BMW iFE.20 is the first works BMW racing car in which the material is used. However, the expansion of this concept to include other BMW Motorsport race cars is currently already in the development phase.”

More information on the iFE20 cooling system appears here.

BMW’s Alexander Sims leads Formula E drivers’ points going into the January 18 race in Santiago, Chile.—Brian Morgan

[Photos courtesy BMW Motorsport.]