Racing is a science. From the grandstands, it’s easy to appreciate the soul-shattering downshifts of a DTM-spec BMW M4 as it takes the first apex of the course at speed, but it’s in the pits where the engineering of these monstrous machines truly shines, tamed by some of motorsport’s greatest engineers, chemists, and physicists.

In an industry where a kilogram of weight could mean the difference between a podium finish and losing a race, the need to reduce overall vehicle weight is not just urgent, but critical. However, BMW’s solution to weight reduction is not just as simple as stripping out a few interior bits. Instead, it requires a team of meticulous, incredibly talented engineers and scientists to synthesize a new material or re-engineer an existing compound so that it not only outperforms the competition, but conforms to strict DTM, IMSA, GT, or Formula E racing regulations. Since BMW made the decision in May 2019 to say goodbye to the WEC for now, even more research efforts will be devoted to these other series, which means that research is occurring year-round, during the on- and off-season.

One of BMW’s last races in the WEC, the 2019 24 Hours of Le Mans.

So what is the answer to keep race cars light? High performance thermoplastic composites, and a lot of them. Synthesized from glass, kevlar, and carbon fibers, these composites are created from the injection of a molten hot thermoplastic polymer resin into a weave of fibers, which then hardens into the shape of whatever mould they are held.

These composites not only weigh ten to 50% of the weight of a traditional aluminum part (depending on the intended use of the component), but also possess extreme chemical stability and high-temperature resistance. This means that, unlike metals and commonly used alloys, thermoplastic composites disperse heat well and do not get hot, which makes them ideal for use in a race chassis where performance must be consistent at high temperatures for extended periods of time.

Perhaps the most beneficial property of these composites is their tensile strength, which is approximately eight times stronger than aluminum and ten times stronger than steel, a difficult feat to manage. This makes all of the composite-crafted parts on the race car durable and safe, especially in the event of contact or an accident, where structural integrity is important in order to protect the driver’s life.

M-Carbon Compound wheels equipped on the 2016 M4 GTS.

In 2016, the road-going BMW M4 GTS could be had with the optional M Carbon Compound wheels, the love child of BMW’s M Division and BMW Motorsport’s material research and development program. The wheels were engineered from a CFRP/Aluminum composite, making the 2016 M4 GTS the first series car in the world to be fitted with such a material.

Due to the nature of their composition, these wheels were considerably lighter than their aluminum cousins. With less weight working against the car on the track, the result was noticeably quicker acceleration, braking, and handling, a trifecta that every motorsports engineer dreams of perfecting.

M-Carbon Compound wheels were first available as an option in 2016 for the M4 GTS.

Outside of competition, in December 2018, BMW announced SGL Carbon as their official supplier for composite materials for their iNext vehicles, which would include research of materials for both current and future EV generations. This new technology, if successful, has the potential to be adapted to Formula E applications, making it even more significant. While research is primarily conducted in SGL’s headquarters in Wiesbaden, Germany, production mainly occurs within the United States, in their Moses Lake, facility located in Washington State.

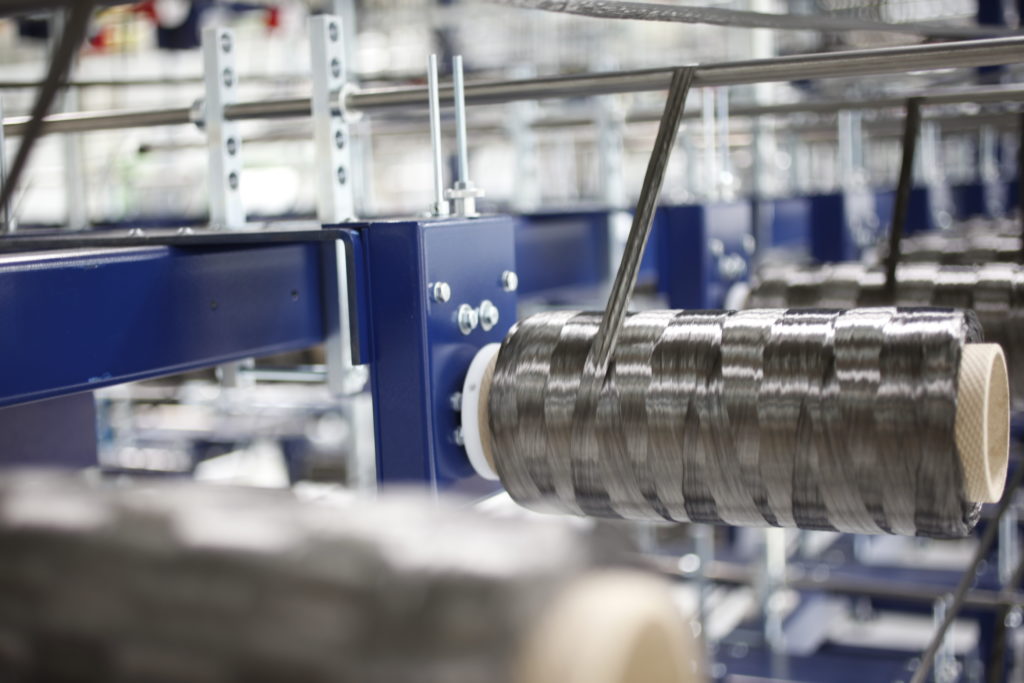

Composite fibers being produced in SGL Carbon’s Moses Lake, Washington facility.

Back in the world of racing, BMW M Motorsport presented in April 2019 a list of their partners and suppliers for the 2019 DTM season, naming Becker Carbon, a leading carbon-fiber specialist company, as the exclusive supplier of BMW’s carbon-fiber reinforced race car components for the season. BMW’s decision to welcome Becker Carbon back into their motorsport division means that we can look forward to more of the crazy aerodynamic modifications that DTM is known for.

Private companies aside, BMW also engineers and tests some of their own composite technology in the Spartanburg, South Carolina manufacturing and R&D facilities. The 5,000,000 square-foot campus, which generates its own power, is home to a 2.4 mile testing track, the Information Technology Research Center, and BMW’s only North American museum, the Zentrum.

BMW’s first all-electric race car, the iFE.18, introduced new carbon-fiber aerodynamic technology to Formula E.

Carbon wings, fenders, body panels, diffusers, canards, and side skirts—you name it. Wherever carbon-fiber can be found, there’s an increased likelihood of a podium finish, and with increasing pressure from the competition, materials research and development is more necessary than ever.

Sleek, aggressive, and ready to tear up the asphalt is how BMW likes its race cars, and it’s how their team of engineers and scientists face the competition. Driver, engineer, or research scientist, it takes a team to make racing as mind-blowing and competitive as it is, and BMW is here to win with innovative technology on its side.—Malia Murphy

[Photos courtesy BMW AG.]