After I submitted last week’s piece describing reassembling and reinstalling the Lama’s head, I thought that I might have the bloody thing running in one more repair session, perhaps even by the end of that very day. This estimate, of course, turned out to be optimistic. While connecting a freshly-installed head isn’t rocket science—it’s just basic stuff like the intake, exhaust, cooling system, belts, fuel lines, vacuum hoses, and electrical connections—it took a while to punch all the way through the list.

There were four main things that slowed me down. First, when I removed the head last month, I was still operating under the fantasy that I could perform arthroscopic surgery on the valve train (e.g., replace the broken rocker arm and drop the still-assembled head back on), so I pulled the head with the manifolds still attached. Of course, when it was clear that the head was going into the machine shop, the manifolds had to be removed—and once you see all that loose, flaky carbon in the intake, there’s no un-seeing it.

I read some posts saying that running the disassembled intake manifold through the dishwasher is a very effective way to clean it.(Some included the caveat, “But don’t tell my wife I told you that.”) I wasn’t prepared to be caught doing that, at least not so close to Thanksgiving, so instead I emptied two cans of brake cleaner into the intake ports and throttle body, scraped off all the carbon I could see and reach with a brush, rinsed it thoroughly with a hose, and repeated the process when I decided it wasn’t good enough the first time.

Second, one of the minuses of my having pulled the head with the intake attached was that I needed to disconnect the portion of the wiring harness that feeds the alternator and starter, and pull it up between the head and the intake manifold. This was enough of a pain that I actually looked forward to installing the head without the intake, figuring that reattaching the lower part of the harness and then bolting on the manifold had to be the easier option. As it happens, it’s quite a PITA threading on and tightening the nuts on the studs at the bottom of the intake, particularly the ones near the starter motor. So, whether you leave the intake attached to the head or remove and reinstall it separately, each approach has its challenges.

Third, there was the now-legendary Hack Mechanic equivalent of the Thai cave rescue. There were a few things I needed to do from under the car, such as attach the exhaust downpipes to the manifolds and get the a/c compressor and power-steering belts snugged down, but I was saving those for last so that I could crawl under the car once and do them together.

One of the final things I needed to do on top before putting the air-flow meter and air filter back on was to re-install the spark plugs. I got to #6, the one at the back of the head, but as I was guiding it in, I clumsily missed the recess for the plug hole. The plug’s electrode slid off the back corner of the head, and the plug, the socket, and the 3/8″ extension slipped from my hand and fell, resulting in a metallic clank. From the sound, I assumed that the trio had hit a heat shield or landed on top of the subframe, bt when I looked, I couldn’t find them.

I jacked up the car and crawled under it: nothing. It was bizarre. I mean, this happens to everyone with 10-mm sockets, but those are little. This was three items that together were the size of a pair of pliers. Then I looked again in the engine compartment, saw the yawning opening of the still-detached exhaust downpipe, and thought… no way.

Could I possibly have been that unlucky? You bet.

I shined a light down the pipe and didn’t see anything, but the downpipe has a dog-leg bend after about eight inches. I broke out the flexible inspection light (also called an endoscope or a borescope) that Maire Anne had bought me about eight years ago. I don’t use it often, and these days you’d probably buy one of the models for $35 that plugs into your phone, but every once in a while, it’s indispensable. I snaked it down the exhaust pipe, and sure enough, clear as day, I could see the head of the extension just past the dog-leg. I’d hit the hole-in-one and nailed the three-pointer from half-court; it was the kind of thing I couldn’t have done a second time if I’d tried.

At least there was no doubt where the extension, socket, and plug went.

At least there was no doubt where the extension, socket, and plug went.

But no problem—just snake a magnetic pick-up tool down the exhaust and pull up pieces, right? I have two magnetic wands, a telescoping one with a strong magnet, and a flexible one with a very small magnet for tight spaces. I first tried the telescoping wand, but it wouldn’t negotiate the bend in the pipe. And unfortunately, the small magnet on the flexible wand wasn’t strong enough to pull the errant pieces up.

What followed was several hours of cutting the magnet off the end of one wand and grafting it onto the other wand, onto a coat hanger, and onto the end of the inspection camera itself, only to have it fall off and become trapped down the exhaust along with the plug, socket, and extension.

Finally I figured out that the problem was that the pieces were wedged in place from their slide down the pipe, and needed more than just a magnet to dislodge them. I was eventually able to bend a hook into the end of a coat hanger, snake it down, watch it with the camera, catch the end of the extension enough to dislodge it, and then pull the pieces out with the magnet. Whew!

Yes, the spark plug could’ve fallen back down the hole while I was taking this picture, but we big-time automotive journalists live for danger.

With l’affaire est bougie allumage finally behind me, I finished the spark-plug installation (yes, this time with a rag stuffed in the exhaust downpipe), reconnected the vacuum lines, filled the cooling system, and tried to start the car for the first time in a month.

I actually felt pretty good about the time frame. I’m not a pro, and even on a 2002 with its simpler, smaller, lighter head configuration, by the time I yank a head, disassemble it, get it to the machine shop, order what the machinist tells me I need, pick it up, reassemble it, reinstall it, button it up, and get the car running again, it’s usually three or four weeks.

The last problem was, strictly speaking, unrelated to the head. I didn’t write about this before I decapitated the car, as the broken rocker and the need to pull the head to fix it was the main act, but before I went all-in, the car had a vexing intermittent no-start problem. Sometimes I’d twist the key and it would fire right up, but sometimes I could crank and crank it without a hint of a burble. When it exhibited this problem last month, it had fuel pressure but either weak spark or no spark. I’d spoken with E28 guru Paul Muskopf about it, and he’d directed me to put a test light across the coil terminals to see if the coil was firing, and plug a Noid light into one of the injector connectors to verify that there was a pulse signal. I’d driven down to Autozone and rented a Noid-light kit, but when I prepared to use it, the car started right up. Since I didn’t know when or if the car would start again, I took that opportunity to back it into the garage and begin the rocker repair.

Now, a month later, after having had its head yanked and re-installed, the problem was back.

I drove back to Autozone, rented the same Noid-light set, hooked a test light across the coil, and verified that, as expected, the car had no spark and no injector pulse. On the one hand, I’d had the entire engine wiring harness peeled back, so there was ample opportunity for something to be broken or connected wrong; but on the other hand, the symptoms were exactly what they were before I’d ripped it apart, only then they were intermittent. I theorized that it might be a grounding issue. I cleaned the main grounds in the engine compartment, but it made no difference.

I swapped messages again with Paul Muskopf. “Are the crank sensors new, or are they the ones that were on the car when you bought it?” he asked. I replied that I recalled that the guy who sold me the Lama told me that he’d changed the crank sensors as part of rousing the car from its five-year-long sit, but then realized that I never checked, which made me feel pretty silly. After all, the seller also said that the fuel system had been cleaned, and I found the return line completely plugged up with rust.

The topside connectors of both the reference and speed sensors didn’t look particularly new. I unplugged them to ohm them out. I don’t really put too much stock in these ohm-out tests, preferring instead to see what signal the sensors actually produce (see my electrical book), but if they fail the ohm-out test completely, the sensor is usually bad. Sure enough, the reference sensor had infinite resistance between Pins 1 and 2. I crawled beneath the car to remove it, and saw that the cable going into the sensor was partially separated.

Clearly these were not new crank sensors.

I recalled that I had a pair of used but tested-good crank sensors in the garage, given to me by my friend Charlie Burke when we both worked at Bentley Publishers. I spent the requisite 30 minutes hunting for them in the post-apocalyptic hellhole that I call a garage, but eventually I unearthed them. I tested and installed them, and when I cracked the key, the Lama fired up instantly. (The video can be seen here.) Knowing that I was over the hump, I shut it off immediately and called it a night before I broke something.

The next morning, I planned to let the car warm up for 30 minutes so I could give the head its final angle-torquing, as specified by the instructions that came with the Reinz head-gasket set. The engine again snapped immediately to attention, but the idle was very high. I found that I’d connected the throttle and cruise-control cables incorrectly, which was pulling the throttle partially open. I corrected my mistake, re-started the car, and it settled into an idle that positively purred (video here).

It had been a month-long slog, but in that single moment, it all felt worthwhile. The Lama was back.

Unfortunately, as the car was warming up, a fair amount of antifreeze began dripping underneath. It was coming from where the lower and upper radiator hoses connect to the water pump and head, respectively. When I reinstalled the head, I’d scraped the corrosion off the coolant necks and re-used both of the old radiator hoses. This turned out to be false economy (what, moi? inconceivable!), as even though I’d wiped the obvious corrosion out of the hoses, their inner surfaces had been damaged, preventing them from sealing.

I was able to detach the upper hose without dumping all the coolant, trim it back to expose a fresh rubber sealing surface, and re-connect it. This squelched its leak. Disconnecting the lower hose, however, would caused my just-poured coolant to flood out. For now, I tightened down on the hose clamp more than I normally would, and that stanched the dripping. It’s likely that I’ll revisit the car’s cooling system, and the next time I have it open, I’ll replace both the lower and upper hoses.

Some of this corrosion got into the hoses.

With the cooling system no longer dripping, I set a timer and let the car warm up for 30 minutes. I currently have the instrument cluster out of the car (I’m replacing the batteries on the SI board), so I have no temperature gauge. The last thing I wanted was to overheat the car during its initial warm-up! I monitored the temperature by feel, laying my hand on the lower radiator hose to make sure it opened. Coincidentally, when the car was within two minutes of the 30-minute timer, the auxiliary electric radiator fan switched on. I took this as both an indication that the car was warmed up, and as an omen that I shouldn’t warm it up further, and shut it off.

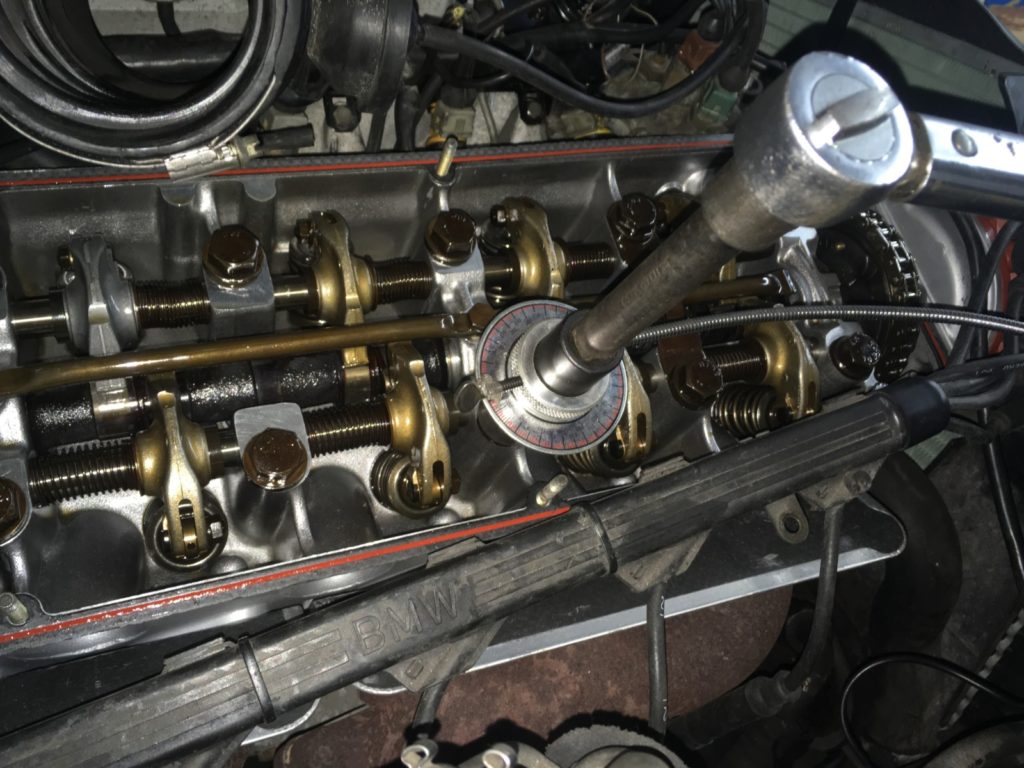

The next morning, I pulled the valve cover off and angle-torqued the head 35 degrees, per the instructions that came with the Reinz gasket set.

When in doubt, follow the instructions.

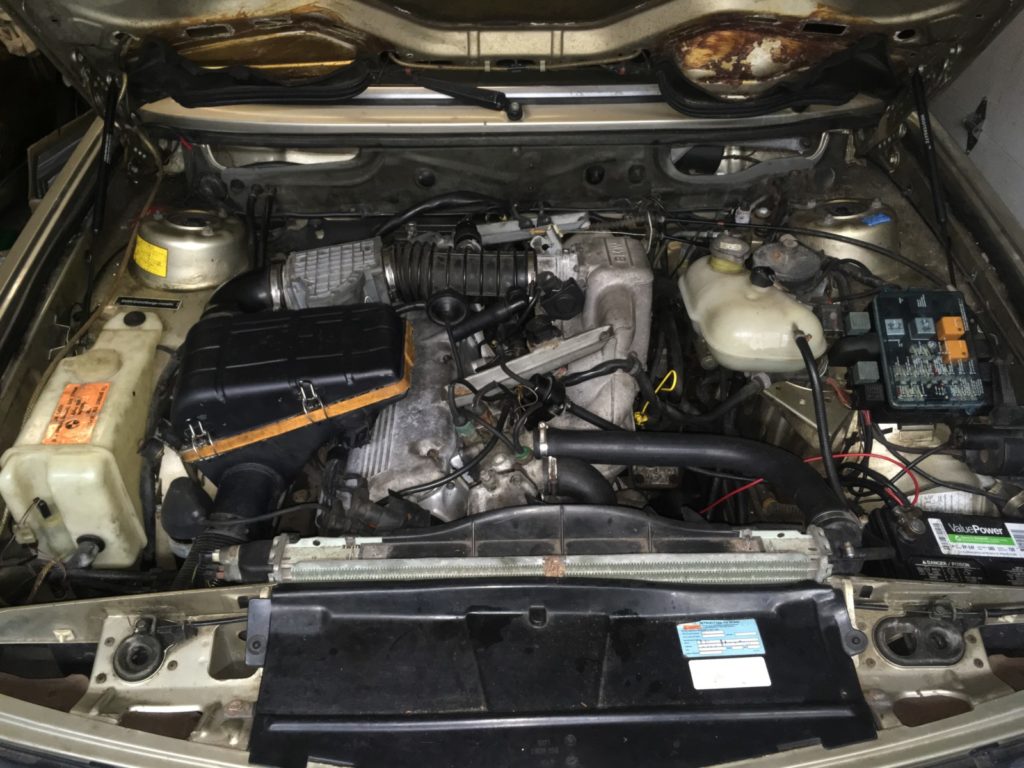

I then reattached the hood (which I’d removed so I could pull and reinstall the head using my ceiling-suspended electric winch), and installed some final items such as the two cross-braces securing the intake manifold to the head.

Buttoned!

That’s where we are. I’d hoped to have the instrument cluster back in and drive the car this weekend, but with an unexpected dump of snowy weather and 30 people expected for Thanksgiving, it’s likely this estimate will also be optimistic.

But we’re close. I look forward to driving the Lama and learning what the car really is and what it really needs, as only then can I begin to get a bead on what its future will be.—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.