Yes, I did a “Decapitating Bertha” piece just a few short months ago. But it’s a good title. And with everything else on this car being harder than anticipated, at least the title should be easy.

When I last wrote about the Lama—the 1987 E28 535i that I bought sight-unseen in Tampa—it had arrived at my house in Newton, Massachusetts, barely running and in much rougher shape than I expected. One item that seemed quite important—at least in those bright early days before I realized how screwed up the car really was—was the fact that it was still sitting on its original TRX wheels and tires. I found a set of E38 16″ basketweaves in Albany for $120; my brother-in-law, who lives out that way, was kind enough to grab them for me. Then I found a set of lightly-used Yokohama 205/55-16s (the correct size for an E28) for a hundred bucks and had them mounted and balanced on the basketweaves. So for $300, the car had proper shoes.

I was quite pleased with myself. Even if the car was rougher than expected, at least it would look sharp.

Next, I began dealing with the fact that the brake pedal went to the floor.

I expected that the car needed a master cylinder, but I thought that first I’d try bleeding the system. Fluid came out of only one caliper, indicating that the flexible lines were plugged. I bought new braided stainless lines and installed them, but I still wasn’t getting fluid from the front left caliper; the blockage appeared to be in the ABS unit. But with the rest of the system bled, at least the pedal no longer went to the floor, making the car drivable.

Out with the old (bottom), in with the new (top).

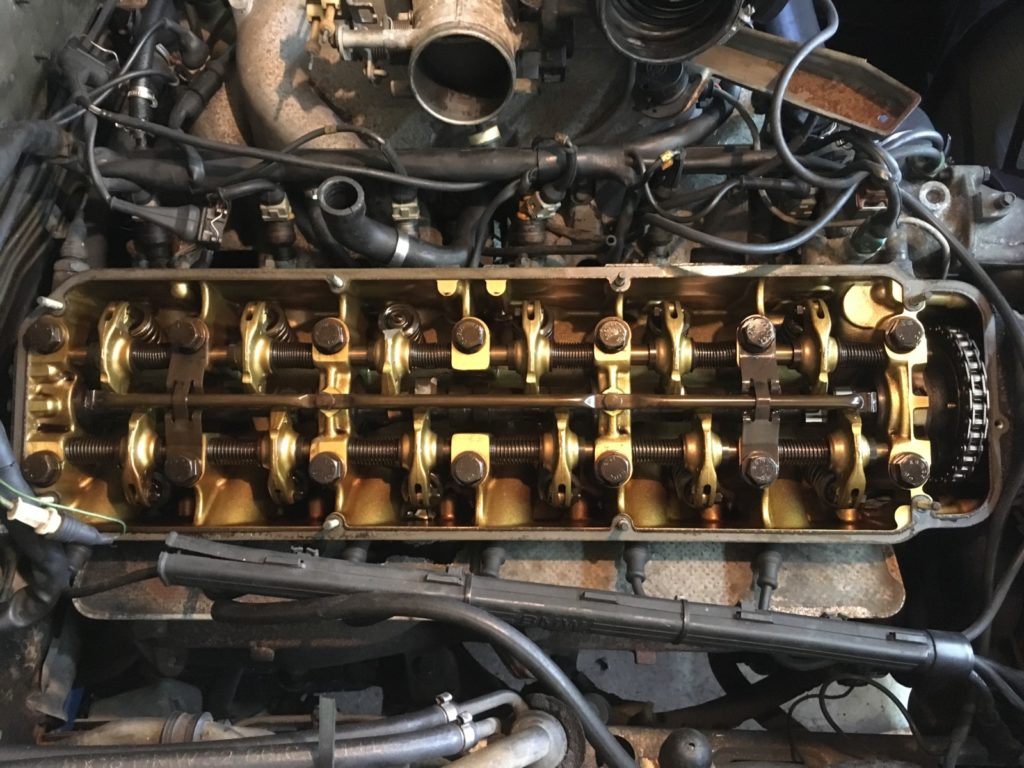

So I drove it. It ran, but badly. It belched clouds of oil smoke, idled and ran rough, and, as I noted in the last article, the valves were loud. The next morning, with the engine dead cold, I pulled the valve cover and began adjusting the valves. Initially I was delighted at the varnish-free appearance of the valvetrain:

This was beautiful.

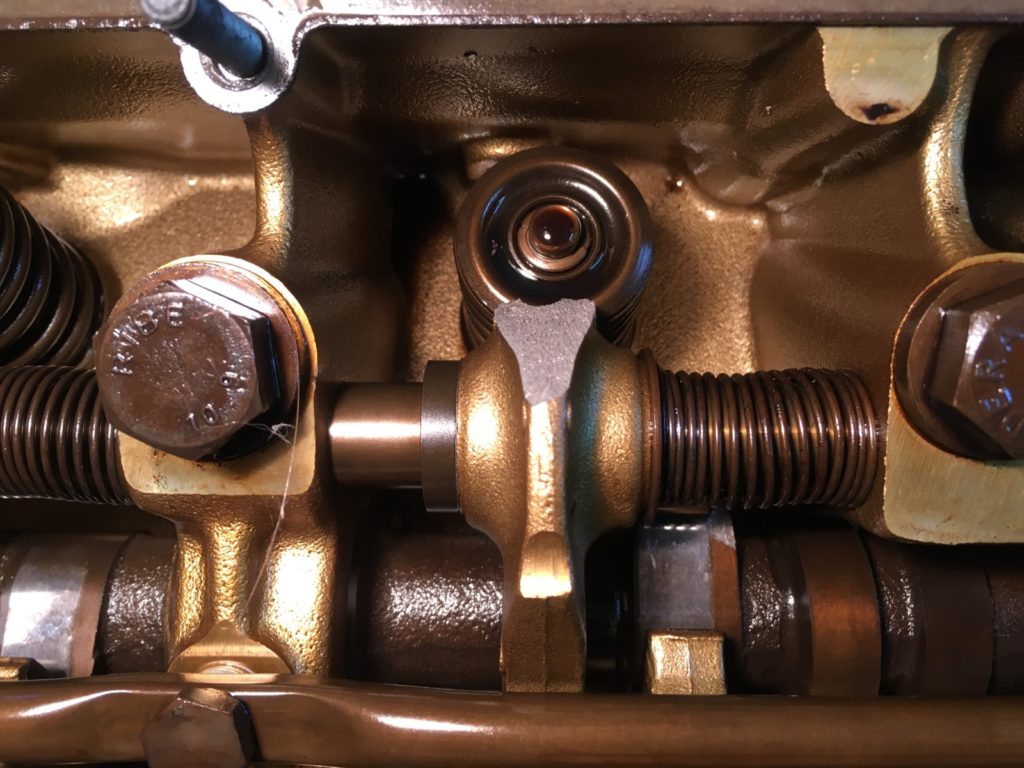

But then, when I went to adjust the #4 intake valve, I gasped. The intake rocker arm was broken!

This was horrifying.

When I looked carefully, I could see how the fragments of the shattered rocker arm had piled up in a corner of the head, like driftwood in a river’s backwater. In addition, in the above photo, you can see how, when the rocker arm broke, a piece that flew off chipped the side of the exhaust lobe of the cam. The chip was mostly outside of the running surface on the cam lobe, but it was still jarring.

Damn. Damn, damn, damn, damn, damn! That’s what I get for buying a car sight-unseen without having a knowledgeable BMW person look at it for me. Had I looked at the car myself, the combination of the visible oil-burning, the valvetrain noise, and the rough running probably would’ve warned me off. I assumed that the car’s $1,400 purchase price was low enough that it had all sorts of risk baked into it, but I was wrong. At the time, the risk made me feel energized, but it didn’t pan out. I kicked myself.

The broken rocker arm explained a lot—not only the fact that the valves sounded loud (the arm was just flailing around, never under tension from the valve spring and instead being smacked by the cam lobe at each rotation) but also the car’s rough running. For the short term, I disconnected the little clip on the left side of the rocker arm that keeps it in position, allowing the retaining spring to push it all the way to the left and off the cam lobe. I reinstalled the valve cover, started the car, and found that the valve clatter was gone, although the engine still idled and ran rough.

To go further and replace the broken rocker arm almost certainly required pulling the head. On a 2002, I can do that in my sleep, but there’s a lot more stuff to disconnect on an E28. Plus, the head on the car’s M30 engine, especially with the intake and exhaust manifolds attached, is quite a bit heavier than an 02 head.

My friends Paul Muskopf and Tom Jones raised the tantalizing possibility that since the rocker arms for Valve #4 are at the end of the rear rocker shaft, it is theoretically possible to pull the rear head bolts, unclip the rocker arms, slide the shaft backward in the head, slide the broken rocker arm off, and install a new arm—all with the head on the car. I bought a set of plastic-jawed non-marring pliers, but I could not budge the rocker shaft. And I was afraid to use Vise Grips, because if you mar the shaft, it makes it all the more difficult to take it out of the head the normal way.

I thought about it and decided… no. I did not want to go to the work to pull the head. The thing to do was fix a few small issues on the car and bail out of it before the snow fell. I didn’t think I’d have a problem selling it for what I had in it—$2,100 without the E38 wheels and tires, $2400 with.

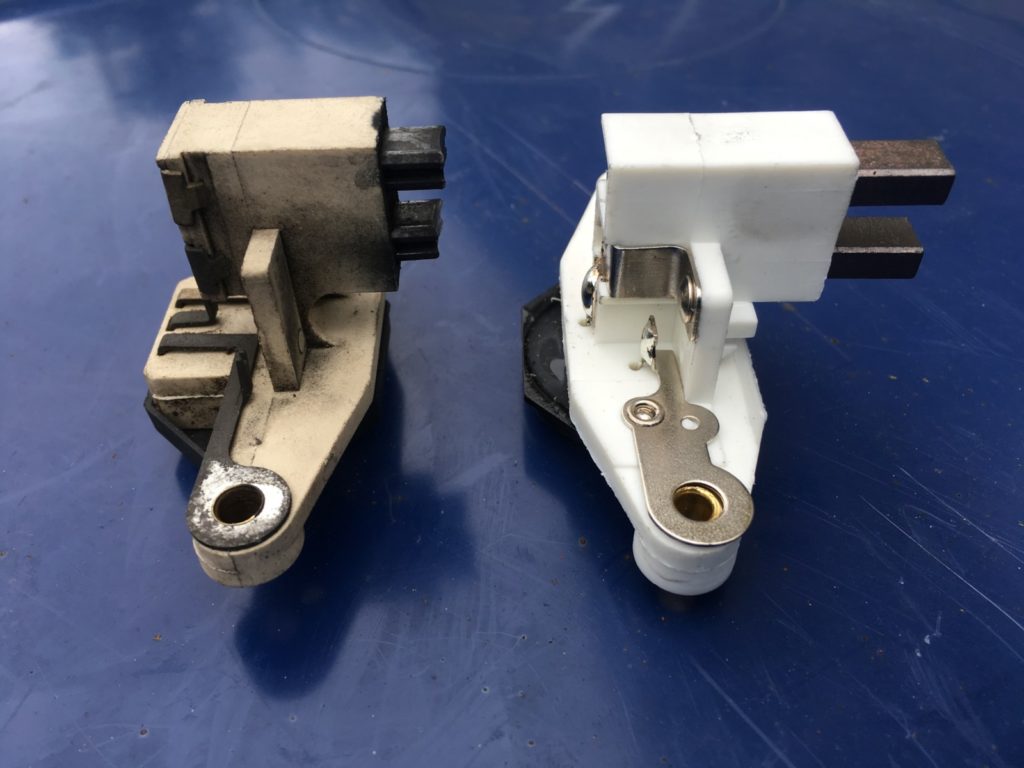

So I clocked through a short punch list. The car had an intermittent no-charging issue; it was obvious because when it would occur, many of the dashboard lights would remain illuminated due to low voltage. I pulled the voltage regulator out of the back of the alternator and found that one of the brushes was worn way down. Replacement cured the problem.

It’s probably obvious, but the bad voltage regulator is on the left, and the new one is on the right.

The next issue was the fact that the car not only ran rough, the exhaust was eye-wateringly rich. I put a pressure gauge on the fuel rail, and it pegged at over 100 psi. This indicated to me that the fuel-pressure regulator wasn’t doing its job. But then a friend advised that a plugged fuel-return line had the same symptoms. He was exactly right; I blew the return line out with compressed air, using a plastic bottle to capture a big blast of rusty snot. However, to my surprise, the fuel-pressure gauge was still pegged.

All this crud blew out of the fuel-return line, but that didn’t solve the problem.

I recalled that I had the same problem in Old Blue, the ’73 2002tii I’d sorted and sold a few years back, and the cause was that the return part of the pick-up tube in the tank was clogged. I yanked the Lama’s pick-up tube, and bingo! After ten minutes working with a stiff piece of wire, a can of brake cleaner, and compressed air, the return line was free. The car idled and ran noticeably better (about how you would expect a six-cylinder engine running on five cylinders would), although it still burned quite a bit of oil.

With the car starting, running, and stopping well enough to show it, I wrote up one of my traditional hyper-detailed Craigslist ads, candidly listing the car’s many foibles, including the broken rocker arm, and floated it for sale on both Craigslist and Facebook, encouraging offers.

With the E28 basketweaves on it, it looked right sharp. I got a number of inquiries, but they all turned out to be from people who were simply responding to the photos (the tip-off was when someone asked, “Does it need any work?”). Only one person came and saw it, a kid who drove an E90 and had no idea what he was getting into. I flatly told him, “If you don’t work on your own cars, you shouldn’t even think about buying this.”

The photos in the ad looked so good that a number of people didn’t read the laundry list of problems.

I wondered how I’d gotten myself into this. When I bought the Lama, I was seeing clean E28s go on Bring A Trailer for $6,000 to $50,000. Now, the cars on BAT are usually in excellent condition, and thus skew to the high end, price-wise, but in addition, I’d also looked locally on Craigslist, and the only E28s I saw within 500 miles for less than $3,500 were rusty junk. With that info, I thought that for $1,400 to buy it and $700 to ship it, I was getting a car where I could sort out whatever running issues it had after sitting for five years, fix a few rust bubbles and a torn driver’s seat, flip the car, and make some money. It wasn’t until more recently that I looked at prices on myE28.com and the Facebook E28 Owner’s Group and began seeing non-rust-bucket running cars (like mine but without broken rocker arms) in the $2,000-to-$2500 range. So the issue was that, even without the broken rocker arm, I’d fundamentally misjudged the value of the car.

With no interest in it as-is, I needed to fix it—or dump it at a loss.

I figured that if I was lucky, I could yank the head, slide the rocker shaft back, replace the rocker arm, and drop the head back on. Arthroscopic surgery it ain’t, but at least it would be mostly labor: $70 for a head gasket, $13 for the rocker arm, some ancillaries—maybe a hundred bucks… if I was lucky. But I tend to be a pretty lucky guy (cough broken rocker cough). Yeah, maybe this made sense. It fit with my self-image of rescuer and foster parent of vintage BMWs. And it certainly made for a better story than simply bailing out.

And thus I began to slide down the slippery slope of pulling the Lama’s head. To be (obviously, painfully) continued.—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.