The BMW 7 series has long been a benchmark in terms of luxury and comfort, and in the course of developing the next generation, whose model lineup will include an all-electric variant called the i7, refinement remains a top priority. With the highest level of well-being in the luxury segment as the goal, BMW has been subjecting prototypes of the i7 and next-generation 7 Series to a barrage of different tests and evaluation methods at its new Munich research and development center, referred to as FIZ North. Noise insulation, aeroacoustics, and vibration comfort are all being looked at, in addition to how electromagnetic fields influence the various systems and pieces of technology that make up the vehicle and allow it to function.

As with other electric BMW models such as the i4 and iX, drivers of the upcoming i7 will be able to choose between riding in silence or being treated to an aural experience which comes courtesy of academy award-winning Hollywood film music composer Hans Zimmer. We’ve already talked about what BMW refers to as BMW IconicSounds Electric and BMW M IconicSounds Electric (the version found in M Performance models like the i4 M50 and iX M60), but achieving near-silence in a vehicle rolling over pavement at high speed is not particularly easy. The new Rolls-Royce Ghost is apparently so quiet, that development engineers added a specific humming noise to the interior so occupants do not become disoriented. For the next-generation 7 Series, which comes from a lineage that often shares technology and componentry with Rolls-Royce, it sounds like a similar level of isolation is being targeted.

New Materials And Insulation

The battery of tests the i7 and 7 Series prototypes are being subjected to includes acoustic evaluations in which the vehicles are placed on roller dynamometers with interchangeable surface coverings that allow for the replication of driving surfaces and relevant day-to-day traffic conditions anywhere in the world, according to BMW. The same can be said for the loud speakers which surround the prototypes in another test, which is intended to simulate the acoustic properties of other vehicles and driving scenarios, including being surrounded by traffic and examples such as passing trucks or being near a road construction site. Some of the steps taken to make the upcoming 7 Series the quietest yet include the use of lightweight foam noise absorbers within the tires, interior pillar trim, seats, headliner, and rear parcel shelf, along with comfort glazing, which allows the glass of the window panes to prevent unwelcome noise from entering the cabin.

Special attention was also paid to ensure that the electric drive system of the i7, which is comprised of two electric motors, can deliver power in silence. As opposed to other applications, the electric motors of the i7 use a model-specific mounting design and are encapsulated within a new enclosure that’s designed to contain noise. BMW says these measures allow the i7 to achieve what’s described as effective acoustic decoupling across a wide frequency range, which translates to acoustic comfort within the cabin during all driving scenarios.

Aeroacoustics

Another area in which engineers were focused on the noise comfort of the i7 and next-generation 7 Series is that of aeroacoustics. BMW’s FIZ North research and development center is home to both a climate test bench and a wind tunnel. On the climate test bench, test mules are subjected to what BMW refers to as globally relevant conditions which allow for analysis of a wide variety of noise sources. Examples include how the climate control system sounds throughout the entire vehicle at opposite extremes of the temperature spectrum, including very hot and very cold.

Similar to the way road surfaces play crucial role in noise, vibration, and harshness (NVH), air flowing over the different surfaces of a vehicle is also of particular importance. As far as the i7 is concerned, the use of flush door handles, clear-cut body surfaces, aerodynamic exterior mirrors, and an underside that is almost completely covered with plastic cladding not only allow for decreased drag, but also an exceptionally quiet driving experience.

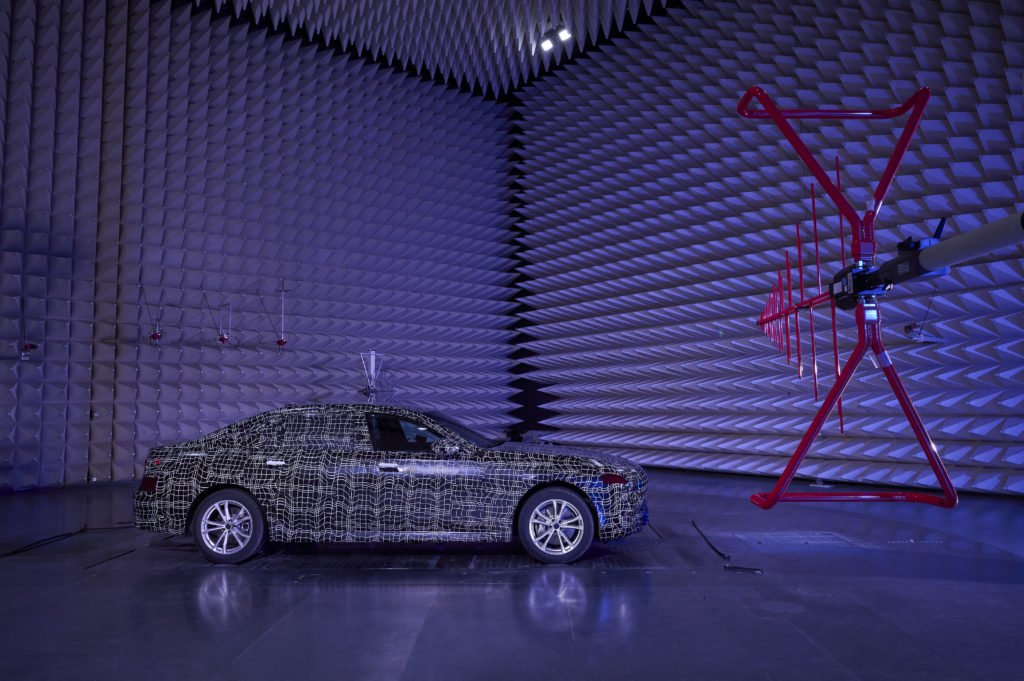

Electromagnetic Interference

As the prevalence of electronic systems within consumer automobiles continues to grow and expand, so too does the importance of ensuring that they can operate in a world full of interference. Much of this interference originates from the various electromagnetic fields we unconsciously traverse every day, and to simulate what a vehicle will encounter over a lifetime of use, BMW analyzes electromagnetic compatibility (EMC).

The testing takes place in the EMC absorber hall within the FIZ North facility, and includes prototypes being exposed to powerful electromagnetic fields to determine just how susceptible the numerous systems are to inference, and how they interact with their surroundings. Arrays of antennas and other sources of potential interference are pointed at the prototypes in the insulated test chamber while engineers monitor and analyze diagnostic results from the vehicles which are transmitted in real time by way of fiber-optic cables. The end goals are to ensure comprehensive protection of the vehicle, absolute reliability of suspension and assistance systems, and interference-free reception of various signals for things such as your phone, the navigation system, data, and more.—Alex Tock

[Photos courtesy BMW AG.]