According to a report out of Germany by weekly business news magazine WirtschaftsWoche, demand for the BMW i4 is high enough that the automaker is planning to introduce Saturday shifts at its main Munich plant in response. Although the first production examples of the i4 were delivered in Munich at the end of November, three months ahead of schedule, the wait time for the new model is said to be approximately nine months, and could soon stretch to as long as one year.

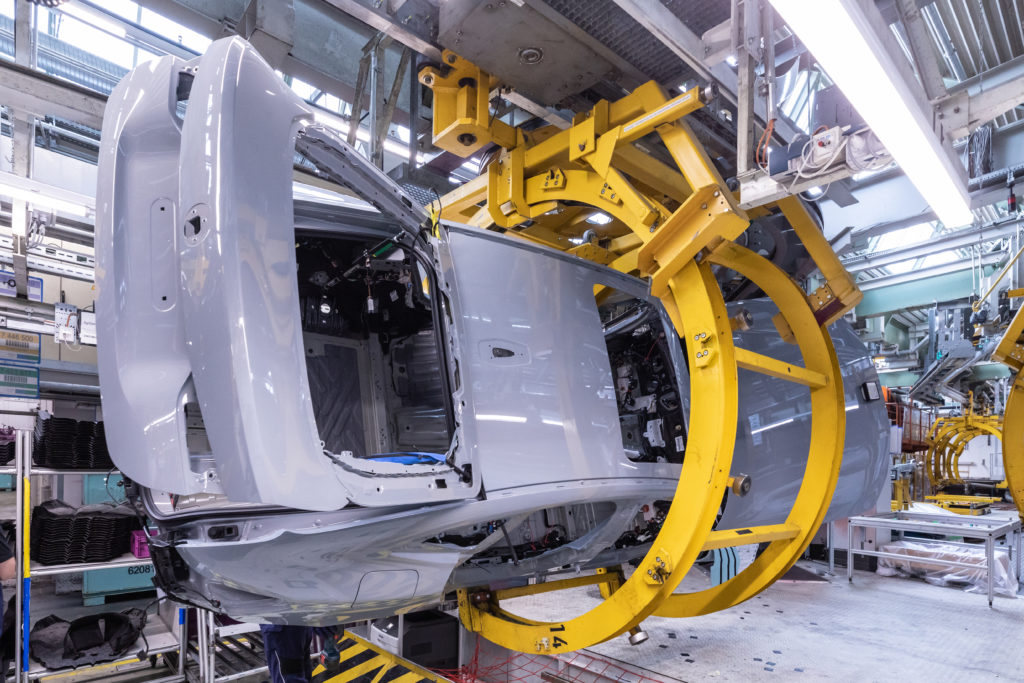

Demand for the i4, which is described as higher than expected, could prompt the introduction of Saturday shifts at BMW Group Plant Munich as early as the first quarter of next year. Series production of the i4 began in late October, just over one month before the first examples of the car met their new owners. In addition to the i4, BMW’s main production hall in Munich is also responsible for manufacturing the 3 Series in sedan and touring form, the 4 Series Gran Coupé, and the M3. Adding the all-electric i4 to the production schedule, which shares many of its parts with the 3 Series and 4 Series Gran Coupé, required retooling significant enough for the plant to pause production during the summer of 2020, a process that was largely completed last September.

It has been suggested that BMW’s newest plant, located in San Luis Potosi, Mexico, could also theoretically produce the i4, as the factory currently manufactures the G20 3 Series and G42 2 Series coupe. While the line at BMW Group Plant San Luis Potosi could likely accommodate the i4 with appropriate retooling, battery and electric motor manufacturing are largely concentrated in Germany within BMW’s global production network.

Although none of the plans have been confirmed, a spokeswoman for BMW is quoted as saying “We are thus able to expand the volume, for example by adding additional shifts, and thus meet the pleasingly high demand,” according to WirtschaftsWoche.—Alex Tock

[Photos courtesy BMW AG.]