The first BMW i4 of the production series rolled off the assembly line at BMW’s home plant in Munich this week. With the addition of BMW’s important entrance into the market of electric vehicles to the production schedule, BMW Group Plant Munich, the oldest in the automaker’s global decentralized manufacturing network, now produces a wide range of vehicles which includes the 3 Series sedan and touring, the 4 Series Gran Coupé, and the M3. All of the different variants of these vehicles with different drivetrain configurations are manufactured on a single line, something that has long been a feather in the cap for BMW in terms of production capability.

“For the plant and team, the launch of the BMW i4 is a milestone on the road to electric mobility,” said Milan Nedeljković, BMW AG Board Member for production. “By 2023 more than half of all vehicles from our Munich facility will have an electrified drive. The majority will be fully electric. So Munich goes fully electric.”

Even though the i4, 3 Series, 4 Series Gran Coupé, and M3 are all produced on the same assembly line, the preparation required to accomplish such a feat was substantial. Production at BMW Group Plant Munich was stopped for roughly six weeks during the summer of 2020 specifically to allow for retooling ahead of i4 production. On the ever-important sustainability front, production of both the i4 in Munich and the iX in Dingolfing is powered by local hydroelectric facilities.

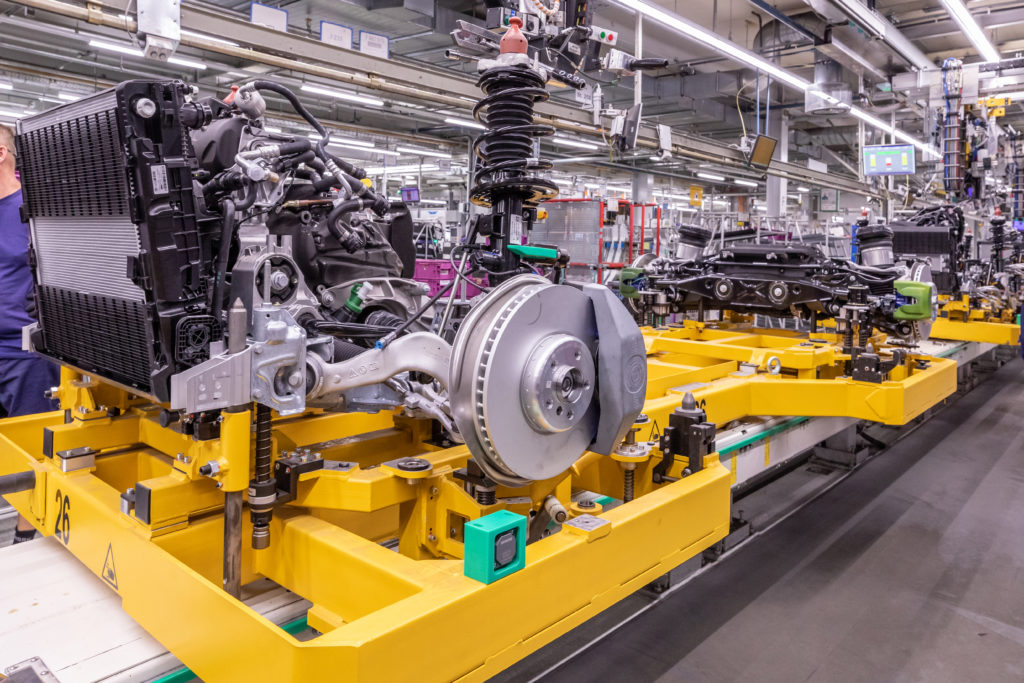

In addition to demonstrating BMW’s production prowess, with 90% of the existing systems in the Munich plant’s bodyshop able to accommodate i4 production, the latest addition to the plant’s repertoire is proving to be valuable in other ways. Earlier this year, we reported on BMW working with Nvidia and the tech company’s Omniverse platform to aid in factory planning. The system was used to plan axle pre-assembly for the i4, with Omniverse able to create a photorealistic real-time simulation before anything had been bolted to the factory floor, effectively eliminating bottlenecks before they could form. Nividia’s Omniverse is also able to process three-dimensional scans of factory layouts, which have already been performed at places like Spartanburg and Regensburg, with the process currently taking place at Dingolfing, where the iX is being built. BMW says the structure of all major plants within the production network will have been scanned and interpreted by the end of next year.

BMW Group Plant Munich began sourcing onsite groundwater for production in 1997, and the natural resource provides roughly half of the facility’s requirements. Recently, the use of reverse osmosis was initiated at the plant specifically in relation to the cathodic dip process that vehicle bodies undergo for the application of paint base coat. The water required for the process is now being reused, which is estimated to save nearly 1,600,000 gallons of fresh water that would otherwise be necessary.

Elsewhere, RFID technology is being used to streamline production, with parts identified and sent where they need to go seamlessly in a contactless and automated progression. First used in seat production, RFID is now being used in the form of smart labels on a variety of different parts bound for different cars, each outfitted with different packages, options, and other choices.

BMW summarizes these developments as paving the way for the upcoming Neue Klasse platform, which is slated to arrive around 2025. By 2024, Munich is expected to go fully electric, with internal combustion engine production being moved to Steyr, Austria and Hams Hall in the U.K., the latter of which being where four-cylinder BMW engines will be produced starting at the end of this year. As of late last year, another production line is also being added to BMW Group Plant Munich.

In the U.S., the i4 is offered in two variations. The i4 eDrive40 starts at $55,400, develops the equivalent of 335 horsepower, has a range of approximately 300 miles, and can sprint from zero to 60 mph in 5.5 seconds, according to BMW. The i4 M50 is the first all-electric M Performance model, starts at $65,900, develops the equivalent of 536 horsepower (more than the M3 Competition), and can hit 60 mph from a dead stop in 3.7 seconds, per BMW. June 2022 delivery allocations for both variants sold out shortly after the new model was officially announced, and the current delivery window for an i4 is for the summer of 2022.—Alex Tock

[Photos courtesy BMW AG.]