Growing up, I helped my dad with quite a few woodworking projects and even completed a few of my own. Recently, I decided to get back into the hobby because apparently my BMWs aren’t keeping me busy enough in the off-season of racing. So, I called my dad and we planned a few projects to build in his woodworking shop, which would allow me to relearn a forgotten skill set and make use of all his wonderful selection of tools.

We spent a couple of weekends building plant shelves and an entertainment center for my living room. Cutting into a piece of oak slab filled the shop with a familiar smell and it took me back to the time I helped my father build a porch swing of oak. After a couple successful projects in his shop and under his tutelage, I was excited to build even more.

Like many of us who want to take on projects, my biggest hurdle was a lack of tools and work space. Unbeknownst to me, I would be getting an early Christmas gift from my partner Calvin. He saw me pining—pun intended!—over miter saws and decided one would make for a nice surprise. There was a catch—he gave it to me early under the condition that I build him something for Christmas. I was excited because handmade gifts are my favorite to give.

I could have gone online and found plans to build a simple wooden bench, but I knew that Calvin (like most of us gearheads) would love something more like the furniture from the Top Gear set. And since we are proper BMW hoarders, I grabbed a set of E46 sport seats from our vast parts inventory and measured them to work into my design.

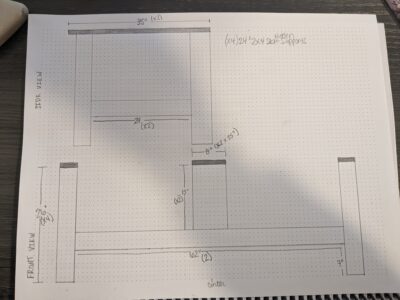

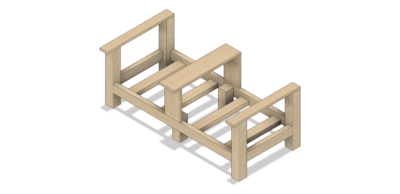

This was only the second woodworking project that I have designed myself. I am one of those people who love the design and planning phases of a project almost as much as building it, so I spent a couple evenings on the couch sketching my idea onto grid paper and researching ideal dimensions for seating. I wanted to create something that looked like an actual piece of furniture rather than just a couple seats bolted to some two-by-fours. To help me visualize the project even better, Calvin took my design and created a virtual 3D version using computer-aided design (CAD) software, Autodesk Fusion.

- I sketched my idea out on grid paper first.

- Calvin helped me make this 3D model in Autodesk Fusion.

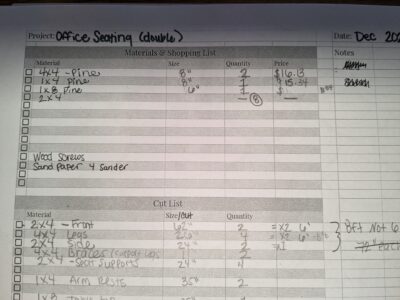

Armed with my list of materials, I ventured into one of the few places I enjoy shopping: the hardware store. I decided on pine due to its cost effectiveness and lighter weight—this wasn’t going to be a small piece of furniture and the E46 sport seats were already quite heavy on their own.While at the hardware store, I also purchased the last items I would need: a pocket hole jig and screws for assembly.

I created this handy little project sheet to help me manage the project. I really like spreadsheets.

Once back at the shop, I had to make space. I pushed two in-progress race cars to the front of the shop bay, one being the E46 rally car that donated its seats for this bench. A welding table became my work bench and I got to work on my cut list. The new miter saw and I made quick work of the cuts.

- My improvised workspace at the back of a shop bay.

- My pile of cut pieces.

This project could have been built in a day, but as we also run a business, projects like this are never short of interruptions. When time allowed, After all the cuts were completed, I began drilling the pocket holes, referencing my plans to remember which direction they all needed to face. The next task was sanding all the pieces before assembly.

So far things were going great, but assembly is usually where you find the problems. I grabbed a couple scraps and tested the depth for the pocket hole jig. It was then I discovered I got the wrong screws. No BMW project is complete without an extra visit to the parts—I mean hardware—store.

- Sanding away all of the stamps and pencil marks.

When I began assembly and saw how everything was coming together, I realized I needed to make several changes. My dad suggested that I add more support to the center of the brench’s frame, so I cut two additional uprights from the four-by-four. Calvin pointed out that the E46 sports seats have adjustable depth. I wanted to hide the seat rails as much as possible, so I used two two-by-fours around the frame allowing me to mount the seats even lower.

For me, a woodworking project really comes together with stain and seal. That’s when it goes from looking like raw materials to a finished product. I chose a reddish brown color to compliment the black seats and mimic the BMW maple trim available in the E46.

After the bench frame was complete, it was seat-mounting time! Overall, this was far from a perfect project and there are a few things that I would change. I am usually my own worst critic, but once this BMW bench was placed in the office, I was really proud of my first solo project.

I’m only five feet tall, so the bench looks quite large with me seated, but I wanted to ensure it was comfortable and accessible for folks of all sizes. This project combined two things I enjoy—BMWs and woodworking—and has inspired me to use more BMW parts to re-decorate our office space so it feels just as warm and comfortable as these seats. —Kelsey Stephens

- The finished bench with E46 sport seats.

- I had to be the first to take it for a test drive!