A few weeks ago, I wrote about taking Rene, my ’73 3.0CSi, down to Oktoberfest in Rhode Island. I mentioned that I planned to take my best girl in her permanent painted-on red dress and Alpina shoes to Vintage at Saratoga the following weekend, but a poor weather forecast kept us safe and dry at home.

However, another chance to drive my favorite car appeared on the radar—a Facebook exchange with an old friend I hadn’t seen since junior high school 50 years ago had me hastily shoot out to Amherst, Massachusetts for the day. Although I’m originally from Old Bethpage, Long Island, my family moved up to Amherst in 1969 when I was eleven, and we lived there for most of the next twelve years, so my emotional ties to Amherst have always been stronger than my actual Long Island roots. And, from a BMW standpoint, as I’ve repeatedly said, Amherst was ground zero for me, as it was a 2002-owning Hampshire College student’s living with us for the summer and driving me around the twisty back roads that burned the car into my consciousness. Plus, the fall foliage was starting to boil. It doesn’t take much to trigger me to pleasure-drive out to Amherst anyway (it’s only about another 25 miles from the warehouse in Monson where I store cars), but add in the the lures of seeing an old friend, the foliage, and taking my Rene my favorite car, and it was a slam-dunk.

Fortunately, unlike the trip to Oktoberfest where Rene greeted me in the garage with a frozen clutch and then had an odd voltage supply issue to the coil didn’t repeat. I threw my travel toolbox, a multimeter, and a can of Fix-O-Flat in the trunk, checked the oil, and headed west. I did note that the oil looked pretty black, realized that I couldn’t remember when I last changed it (I’m horrible about writing down mileage), and resolved to give Rene some maintenance time when I returned.

Rene in Newton before hitting the road.

The drive was flawless, the colors rich, and my visit with my old friend meaningful, so much so that I was in the moment and didn’t take any photos of the red coupe in the glorious western Massachusetts foliage. The only automotive issue was that I did notice that the valve train seemed a little bit more clattery than in years past. As was the case with the oil, I couldn’t recall when I’d last adjusted Rene’s valves. I doubled down on my resolve to pay a bit more attention to the maintenance needs of my favorite car, and I kept up my end of the bargain—when I arrived home, I pulled out the M Coupe and backed Rene directly into the garage’s prime service position over the mid-rise lift.

Now, let me preface what follows by saying that I know that, at this point in my life, I’m complaining more than I probably should about two things—the downsides of storing cars in Monson, and my issues with back pain—and y’all are probably sick of hearing about both. The storage issues—”mister stores-four-vintage-BMWs-and-a-Lotus and complains when he finds mildew talk about first world problems well boo freaking hoo”—you can commiserate with me about or not, but I write about them because I’m a working schmo who pinches pennies to afford his passion and not some moneyed collector who drops mortgage-payment money for climate-controlled storage. The back pain issues I suspect are shared by a fair number of folks like me who were born during the Eisenhower administration. Over the past fourteen, months my back issues have oscillated from life-changing oh crap I can’t do anything anymore, to yeah this is okay as long as I don’t lift anything stupid, to back closer to me wondering if I’m in denial over the possibility that this part of my life needs to wind down while I rock on the front porch and read about how to craft with pinecones and lint.

So it’s with that background that I approach two things that used to be, and still should be, trivial—changing the oil and adjusting the valves.

I began with the oil. I donned the ritual Tyvek suit, skooched under the car, placed the oil drain pan, undid the 19-mm drain bolt, and let the blackened 20W50 run into the pan. As soon as it began streaming out, I thought “Damn! I forgot to warm up the engine first!” No matter. It was probably almost 60 degrees out. It’s not like it glug-glug-glugged out like winter sludge. But seeing it stream out without any clarity to it confirmed what I saw on the dipstick—it was old and black.

Yup.

But really, no matter how long it had been since I’d changed the oil time-wise, it probably hadn’t been that many miles. My usage of the car is such that it simply doesn’t rack them up. Thinking backward, Rene and I went to the Vintage in Asheville in 2022. Before that, Vintage at Saratoga in 2021. Before that, its last road trip was the Coastal Virginia Auto Show in Virginia Beach in 2017, a mostly American-muscle-car event that one of the organizers, a friend and former colleague, invited me to speak at. I’d lay money I changed the oil after I got home. This appeared to be corroborated when I searched my Amazon history and found a winter 2018 purchase of the Mann HU930/3X filter that Rene’s retrofitted E28 533i engine takes. So there was zero chance that I’d, say, put 5,000 miles on conventional oil. But at a minimum, the black oil guilted me into at least writing down the freaking mileage on a scrap of paper this time and sticking it in the glove box. And hey, back-pain-wise, I survived crawling under the car without wincing, so I was ahead of the game.

Speaking of my looking at my purchase history on Amazon, I wound up there partially because I realized that I didn’t appear to have a correct oil filter on the shelves in the garage, so the oil-change part of Rene’s spa day was interrupted. I clicked and bought the Mann oil filter on Amazon. It’ll be here tomorrow. Sorry. Don’t judge me.

Next, I engaged the valve adjustment part of the program. I peered over Rene’s right fender and immediately remembered why I’ve been bad about adjusting its valves.

Hmmmmn.

On a carbureted 2002 or the mechanically-injected 2002tii, or a carbureted 3.0CS or Bavaria, there’s nothing in the way of the valve cover except possibly the spark plug wire loom. Just undo one 10-mm bolt at the front of the valve cover and the six 10-mm nuts along the upper and edges (or eight on a six-cylinder M30 engine) and lift the valve cover up and off its studs. However, the CSi’s original Bosch D-Jetronic injected engine is different, as the throttle body, throttle positioning sensor, and air filter housing all hang over the valve cover. And, more to the point, my car no longer has the D-Jetronic on it. It’s a Frankenstein’s monster of an engine—an M30B32 from a 533i that’s had the Motronics removed and replaced with an L-Jetronic injection system from a 1980 E12 528i. The L-Jet system’s air flow meter really hangs over the valve cover. Fortunately, it’s trivial to pull off, but the auxiliary air valve really is in the way, bolted directly to the valve cover and plumbed with two hoses that are probably no longer available and thus that I really don’t want to crack by muscling them around. Even with the aux air valve removed, the overhang of the throttle body and the wiring harness that runs beneath it makes it difficult to clean dirt off the left edge of the valve cover that might fall down inside the head when you pull it off.

Yeah, that’s really not that much better.

In the photo above, you can see that an added complication is the fat part of the wiring harness that runs through the firewall and feeds the ECU inside the car. I retrofitted all of this into the car in 2001, and I can see that I didn’t do a careful job with the slack on the wiring harness. I simply stuffed some of it behind the back end of the engine. To clean the rear edge of the valve cover, I needed to fish that extra wiring harness slack out, and there was more of it than I remembered.

Looking at all the grit around the edge of the valve cover, I really wished that I’d driven the car into the driveway, warmed it up, soaked the valve cover in engine cleaner, pressure-washed it off, and then put in the service spot in the garage and drained the oil, but that ship had sailed. So I worked my way around the circumference of the valve cover using a little brake cleaner, paper towels, and a toothbrush to clean off as much of the grit, dirt, and grime as I could.

While I was doing all this, it occurred to me that while I usually don’t think twice about re-using valve cover gaskets when I adjust valves, it’d been so long since this one had been changed, and the whole episode would be sufficiently far above the two-minute exercise needed to pop one off and on a 2002, that it’d be worth having a new gasket at the ready. I hopped on FCPEuro.com where I’d been accumulating an order of parts anyway, added the gasket, and submitted the order.

The other issue of concern in this new back-injured landscape is how to rotate the engine to adjust the valves. Although the method of valve adjustment of the E9’s six-cylinder M30 engine is identical to the 2002’s four-cylinder M10 engine other than the wider valve clearance and the presence of two extra sets of valves, there’s no fan clutch on the M10 engine (the cooling fan is bolted directly to the water pump pulley). Because of this, the easiest way to rotate the engine into position to adjust each set of valves is to remove all four spark plugs so you’re not fighting the engine’s compression, put the car in neutral with the handbrake on, grab a fan blade with one hand, and use it rotate the engine with the heel of your other hand on the fan belt to tension it. In contrast, M30 engines all have some sort of a fan clutch. The original fan clutch was primitive, but like most old M30s, this one’s been updated with the E28 style of spin-on viscous fan clutch. The point is that I you can’t rotate the E9’s engine by grabbing the fan blades like you can on a 2002.

That leaves the other two primary methods of rotating the engine—a) putting the car in gear and rocking it, or b) putting a socket on the crank pulley and directly rotating it. Option A is almost certain to immediately anger up my back. I’ve used option B on a variety of cars over the years, but on some cars, there’s’ not enough clearance to get the socket on the crank pulley nut, get the ratchet handle on the socket, and turn it. I just tried it on Rene, and could not even fit the 36-mm socket alone between the crank pulley and the radiator to get it on the nut.

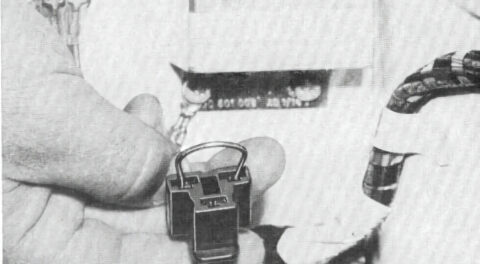

There is one more option—using a specialized BMW tool to grab onto the timing chain and rotate the engine. I recall that I inherited one of these babies as part of a hoard of parts I was gifted. Now I just need to find it in the chaos of my garage and basement.

By this time, my back announced to me that, while it was not yet in acute distress, it had had quite enough of crawling under cars and leaning over engine compartments, so the both of us called it a day.

So, yeah, while in the past, changing oil and adjusting valves wouldn’t be column-worthy, here in my dotage, The Hack Mechanic™: Routine Wrenching Without Wrenching Your Back is actually such viable content that I’m going to stretch it into two parts.

Crikey. I’ve found a whole new business model. Who says age doesn’t bring wisdom?

—Rob Siegel

(Ha! Found the timing chain-grabbing tool!)

BMW tool 11 3 100

____________________________________

Rob’s newest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.