A few weeks ago, I wrote about diagnosing an issue with my 1998 M3 sedan’s over-pressurized cooling system. This led to a failed leak down test at a local shop, CJ Foreign Car Service, which indicated either the head gasket had failed or the head was cracked, allowing exhaust gasses to occupy space it shouldn’t. After weighing my options, ranging from DIY head gasket replacement to an engine swap, I landed somewhere in the middle.

Upon the recommendation of friends, I contacted Alex Garcia, a professional and mobile mechanic, who came to my home and spent a day performing step one—removing the head from my M3’s nearly 250,000-mile 3.2-liter inline-six S52 engine. I had a blast learning from Garcia and helping where I could. I dropped the head off at a local well-regarded machine shop, Tyson’s Automotive Machine, to be tested and milled. And then I went to the beach for a week with my family, burying my head in the sand both literally and metaphorically.

We’re picking this story back up the week I returned from the beach. The machine shop’s owner, Simon, called and let me know the S52’s head checked out. That’s right—no cracks! After Simon cleaned it and milled the mating surface flat, it was ready for pickup—and I was ready to let my fingertips go shopping. I placed a large order with FCP Euro that included an S52 head gasket kit, heater and coolant hoses that I hadn’t already replaced, various sensors, and gobs of other while-you’re-in-there parts. Two large boxes adorned with blue tape arrived the following week and I scheduled round two with Garcia—putting Humpty Dumpty (or Project Concord in this case) back together again. Game on.

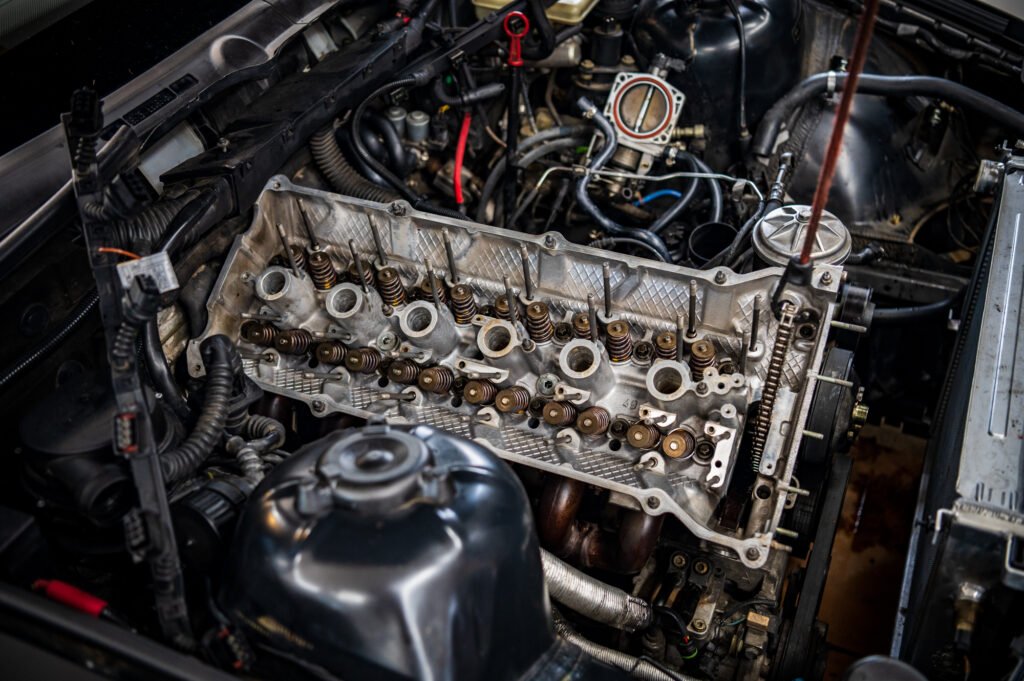

Garcia came over on a very hot Friday. Temperatures quickly hit the mid 90s, and while my garage offered us plenty of space and shade, it didn’t offer us conditioned air. So, an open door, windows on three sides, and a large fan had to make do for providing some relief. The first order of business was prepping the block for the new head gasket and recently tested head. The mating surface was cleaned and the holes for the head bolts were blown out with compressed air. After the gasket was pressed into place over the dowels, we carefully snaked the timing chain through the head and gently lowered the large chunk of aluminum home.

- The block was prepped.

- The head was tested and milled.

I opted for one-time-use stock head bolts as opposed to a reusable set of studs from ARP. Why? This high-mileage M car is just a casual driver for me. It won’t see the stresses of prolonged track use and it won’t be boosted. Also, while I found assisting with S52 head removal and reassembly an enjoyable learning experience, I hoped to never see this M3’s head separated from its block again, so the reusability aspect of ARP studs wasn’t that important to me. And at one-tenth the price, stock head bolts fit the bill (and budget) nicely.

However, the installation of stock S52 head bolts can be a bit unnerving. The torque sequence involves three rounds: first 30 newton meters, then 90 degrees, then another 90 degrees. The second 90-degree turn has you questioning the procedure as it feels like the head bolts will either snap or pull the threads out of the engine block. Thankfully, this wasn’t Garcia’s first time around the block—pun intended! He sets a timer between each torque sequence as the bolts need time to cool down between each step.

After the head was properly clamped down, high fives were exchanged and shelves of parts were reinstalled. Cam trays, cams, timing gears, and VANOS all went on well-lubed and with relative ease, using timing blocks and other specialty tools to ensure everything was set correctly.

- Garcia preps the lifters to go back into the cam trays.

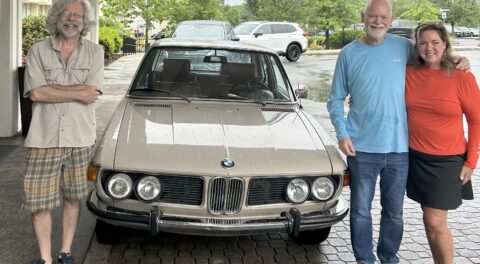

- Another friend, Douglas Lerner, stopped by late morning to check out our progress and share BMW stories. The more the merrier!

- Like a glove!

Part way through the afternoon we were given a reprieve from the heat, though it wasn’t a pleasant one. Heavy rains, thunder, lightning, and even hail cooled things off and provided a bit of excitement as we continued to bring the M3 back to life. With the severe thunderstorm seemingly right above us for almost an hour, lightning strikes outperformed the LED lighting in my garage and Garcia joked that it was as if we were creating Frankenstein’s monster.

As evening arrived, the intake manifold, throttle body, and aftermarket air cleaner were reinstalled, new spark plugs went in, the oil was changed, and the cooling system was filled.

- I’m thinking these heater hoses were original…

- Ah, much better.

Nearly nine hours after we began the journey of reassembly, all the parts were reinstalled and it was time for the final event. Would the M3 start? After reconnecting the battery and priming the fuel system, the S52 fired up and ran smoothly. We both joked, saying “It’s ALIVE!” After a short celebration, we bled the cooling system as assembly lube burned off.

The only minor hiccup was a check engine light for a crankshaft position sensor (code “P0335”), which we decided to postpone troubleshooting for the following morning as it was getting late and we were both gassed—Garcia more so than me as he did the lion’s share of the work. Thankfully, this was a simple and quick fix as only two wiring harness connectors under the intake manifold needed to be swapped. Why are all of the connectors identical!?!

While it was initially a downer to discover my M3’s head gasket had failed, this was a situation where lemonade was made from lemons. It has actually been a very positive experience thanks to Garcia who knocked this job out of the park while teaching me along the way. I certainly couldn’t do the job blindfolded like Garcia, but seeing it broken down into a series of smaller projects (and how to use speciality tools like timing blocks) make it seem less daunting.

Since this project was buttoned up less than a week ago, I’ve been driving my E36 M3 almost exclusively. The boxy 90s styling, the far-out Boa Boa interior, and the torquey S52 engine mated to a proper five-speed transmission puts a smile on my face every time I’m in it. And those smiles will multiply three-fold in just a few weeks. I’ll be taking both my kids on a full-day adventure through the mountains of West Virginia with the National Capital Chapter’s Tours program. This M3 has been given a new lease on life and is begging to get out and carve some corners with friends. —Mike Bevels

Tags: BMW M BMW M3 E36 E36 M3 Head Gasket M3 Project Car S52