Ever since I bought my ’99 M coupe in early 2007, it’s had intermittent problems with the driver’s-side window either not rolling up correctly or making a banging sound at the top of its journey. I first wrote about it in a piece titled “Walking in Hack Footprints” in the July 2007 Roundel; I described pulling off the door panel, removing the airbag and the foam weather liner, and being horrified to find that a large piece of the inside of the door had been jigsaw-cut out, and a piece from another door had been crudely bolted in its place.

I know. WTF, right?

I didn’t know it at the time, but it turns out that in M coupes, it’s pretty common for the bracket that holds the window regulator and motor to crack and break. I believe that a contributing factor is that because the M coupe was built as a skunkworks project from a Z3 convertible, the window seal curls over the top of the window. This requires that the car automatically sense when the door is being opened and drop the window down about half an inch so that it can clear the seal, and then roll back up when the door is closed. Thus, unlike most cars where the windows may be left closed for months during hot or cold weather, in an M coupe, the window automatically goes down and then back up against the limit stop every time you open and close the door. This flexing is bound to aggravate a bracket that’s prone to cracking.

Unfortunately, that bracket is an integral part of the door.

When the cars were still under warranty, dealers would address the problem by replacing the entire door. In the aftermarket, enterprising hacks took to slicing the bracket out, and either finding a good one from a dented door or fixing it and welding it back in place. Although I was initially horrified by what I saw, I came to appreciate the utility of having a section of door-and-bracket that was bolted in place rather than welded there, since over the years I have had to go in and address the cracks several times, and I could simply unbolt the piece, fix it, and bolt it back in.

Almost exactly a year ago, I wrote about the banging problem returning. At the time, I pulled the door apart, looked at it, and saw that the source of the banging was the window regulator smacking against the door’s reinforcement bar. However, I couldn’t find anything that had broken, so I simply put it all back together. I don’t use the M coupe much; it’ll sit in storage or in my driveway for long stretches, so it’s not like I was in danger of having the window bracket or regulator fail completely in the rain on a road trip, or anything like that. I was content to use it as-is and wait for it to fail badly enough that I could see the root cause of the problem.

I discovered this a year ago, but didn’t do anything about it.

As it happened, the failure occurred last week as I was driving the shoe home from getting it inspected. I rolled up the window, heard a loud WHACK, and window functionality ceased. “Good!” I thought. I was a mile from my house. It wasn’t raining. It really couldn’t have been more perfect.

When a window fails like this on a BMW, the cause is usually either the regulator or the little plastic clips that the regulator snaps into to provide the attachment points to the sliders at the bottom of the window. Of course, on my shoe, it could also be the metal door bracket cracking and failing again.

I had some new window clips in the garage. The regulator is usually about $230, but it’s on sale at FCP Euro for $199. I almost clicked and bought, but other than missing the sale, there was no rush. I didn’t need to use the car, so I could do things the right way, which is to pull things apart and see what the problem is before ordering any parts.

So I kicked the Lotus Europa out of the garage for a few days, brought the M coupe inside, backed it into the rear right spot so that I could open up the rarely-used side roll-up door and allow the car’s driver’s-side door to swing fully open, and had at fixing it.

I don’t use this combination of blades on the Swiss Army knife often, but it is handy.

Off with the door panel.

Yup, this is as ugly as I remembered it.

Examining things, I could see a small problem and a big problem. The small problem was that one of the regulator’s attachment points to the window had popped out of its plastic clip. I popped it back in, but I could feel that both it and the other clip were weak in how well they held the post that snaps into it.

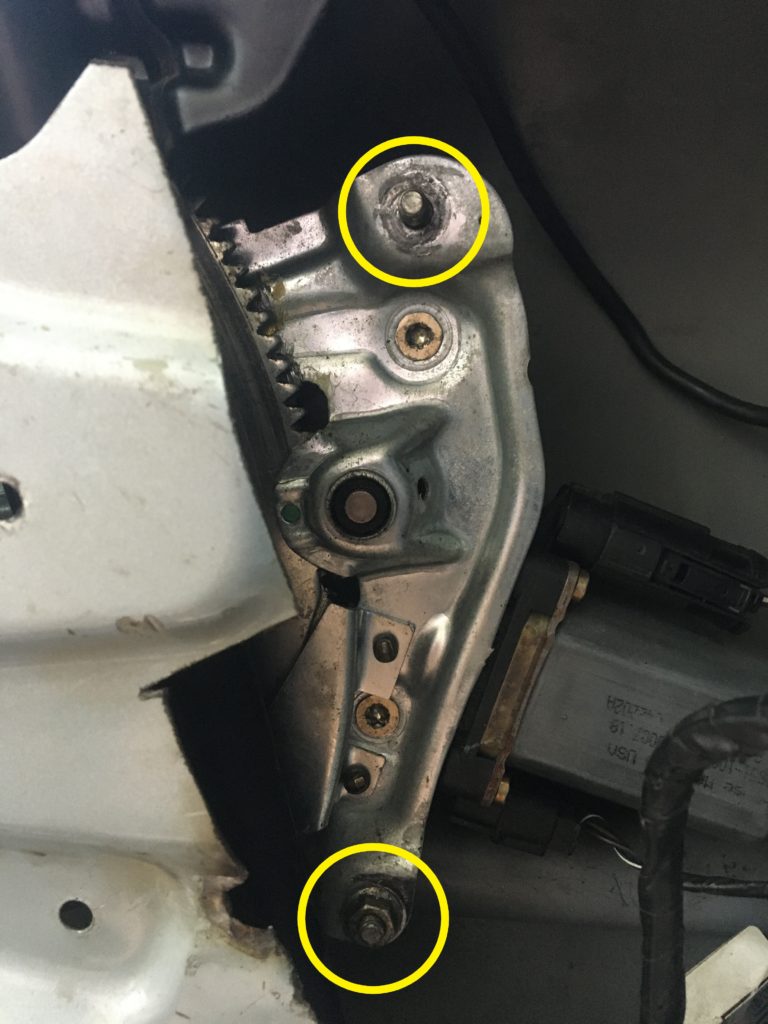

But the far bigger problem was that the regulator was no longer attached to the problematic door bracket.

It’s supposed to be bolted in place with two 10-mm nuts on studs that protrude through holes in the bracket, but instead the regulator was just swingin’ and bangin’ around. I unbolted the strange, but immensely practical, bolted-in door bracket and examined it. It was a mess. I’d had the cracks in it professionally welded probably ten years ago, and did an utter hack welding job on it maybe two three years ago that had separated. And I could see that a few more small cracks had formed.

But in addition, the whole bracket was badly twisted.

This bracket should be vertical. And it’s cracked near the top on both sides.

Then I saw the root cause of the non-functioning window: The nuts and their washers that are supposed to hold the regulator to the bracket had pulled completely through, leaving holes nearly the size of a penny.

That hole should be the size of an M6 threaded stud, not my thumb.

The circles show the studs on the window regulator that go through the holes in the bracket. I’d already removed the 10-mm nut from the top one, but the nut and the broken piece of bracket are still attached to the bottom stud.

I tried to address the bracket’s problems of the twist, the cracks, and the giant holes. I straightened the bracket as best I could using Vise Grips, a block of wood, and a rubber mallet. I made it better, but it was still certainly far from straight. Since my last attempt at welding was so ham-fisted that the bead separated from the metal (I’ve never really put the time into my Millermatic to use it reliably), this time I used J-B Weld, both on the new cracks and where a previously welded seam was pulling away. I also installed a little M6 bolt and 10-mm nut as a backup.

Yup: belt and suspenders.

For the big holes that were made where the M6 studs and their 10-mm nuts tore through, I went to the hardware store, found a set of fender washers that were about the size I needed, and enlarged their center holes so that the studs would fit through them. I almost J-B Welded them in place, but decided to test-fit them dry, since they’d still be held in place by the pressure from the regulator on the back, the remaining lip on the bracket, and the nut.

Bless your local Ace or True Value hardware where you can just walk in, sort through the bins, and find something that’ll work.

I waited overnight for the J-B Weld to dry, then put the bracket back in. I also installed new plastic window clips (I smiled when I saw that the ones I’d found in my garage were still in their original little Bavarian Autosport Ziploc bags). I verified that the window rolled up and down, patted myself on the back, and then buttoned everything up by reinstalling the foam weather barrier, the airbag, and the door card. I closed the door, rolled the window all the way down to reset the lower window limit, and rolled it all the way up.

Bang! Bang! Bang! Bang! Bang! Crap.

It only occurred to me afterward that I was so certain that having replaced the window clips and fixed—at least to some extent—the pulled-through holes in the bracket, the twist, the cracks, I’d not only made the window functional again, but also cured whatever caused the banging that I didn’t think to check them separately. Part of me thought, “Just leave it alone. It’s no worse than it was before the studs pulled out of the bracket. You can just baby it they way you’ve been doing for over a year, rolling it up manually close to the top but not all the way.”

I do, however, like to get to the bottom of problems like this, and this one was really beginning to bug me. Fortunately, it just takes a couple of minutes to pull the door card and the airbag back off, so off they came. Again.

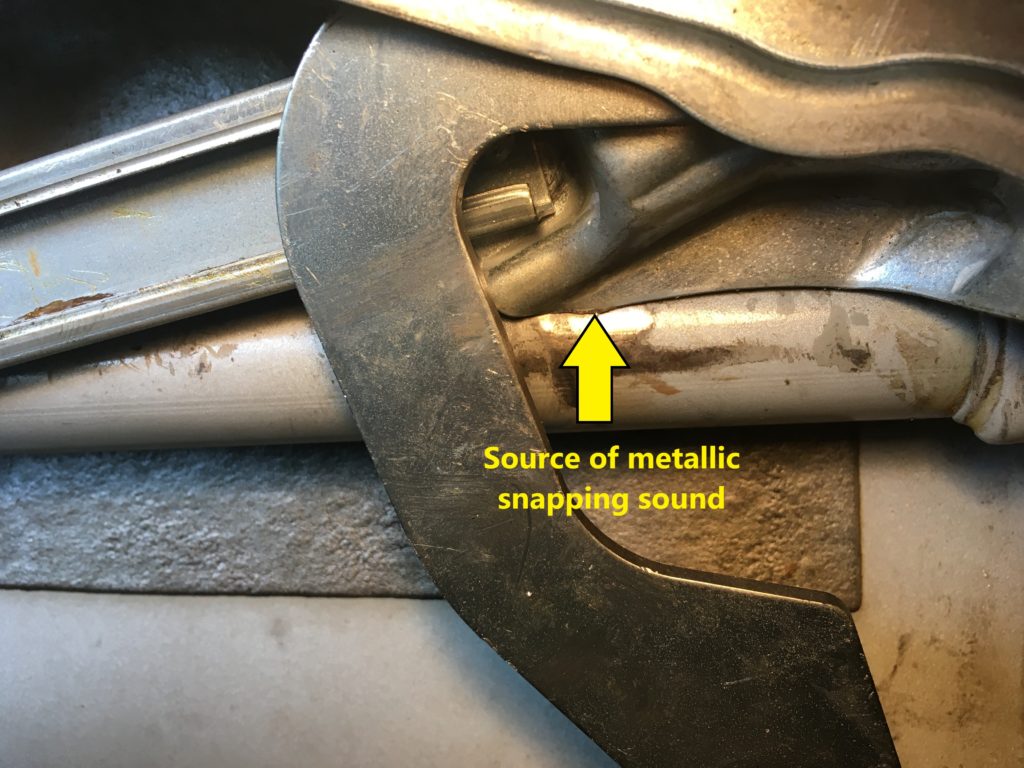

I sat in the car as I rolled the window to its upper extent, where the motor’s internal Hall-effect sensor should detect the slow-down from the regulator’s hitting the limit stop. As was the case the last time I went through this, however, the motor kept turning, and I could see that the banging was coming from the same place that I showed above: the regulator rhythmically smacking against the door-reinforcement rod.

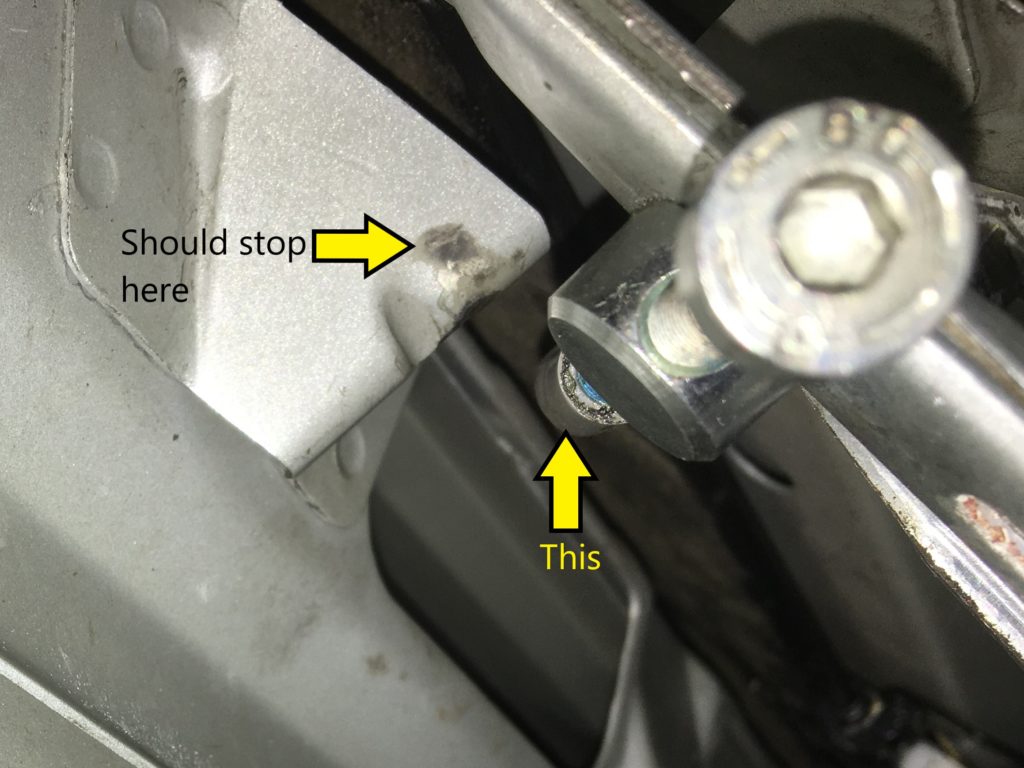

I wondered if the cause of the problem was that the regulator wasn’t stopping where it was supposed to. The limit adjuster is a 5-mm Allen-head bolt on the window regulator; its tip is supposed to come to rest on a little metal tab inside the upper part of the door. The adjuster is easy to see and photograph, but the tab is not. However, by reaching up inside the door, I could easily tell that the plastic or rubber tip of the adjuster bolt was well wide of its landing zone on the metal tab. There’s a little bit of room for the adjuster to rotate, but it wasn’t enough.

These were badly misaligned.

As much as I hated to pull the panel off the other door so that I could look at a working window regulator, it seemed to be the next logical step in terms of seeing whether the adjuster should come to rest on the stop, as well as why the driver’s-side regulator was hitting the door bar. So I rolled the car forward to give it clearance from the Lotus parked next to it, opened the passenger door, and pulled the panel off. When I rolled up the window, I could see that the upper limit adjuster was indeed resting on the tab, validating that this was how it’s supposed to work.

The passenger-door regulator’s upper limit adjuster was right on target.

My eyes then turned to the clearance between the regulator and the door bar. On the passenger door, there was oodles of space between the two. Why the hell were they touching on the driver’s door?

And then I saw something: On the passenger door, the regulator had another attachment point; there was a 10-mm nut threaded onto a stud that went through the back of the regulator, and the stud was secured to a small bracket attached to the door bar. You can’t see it in the photo, but the stud is attached to a cylindrical metal spacer that sits between the regulator and the small bracket.

Surprise!

I looked on the driver’s-side regulator. I saw the corresponding hole in the regulator, but there was no nut, stud, or spacer.

I feel so… empty….

I had to disconnect the regulator in order to get enough clearance to eyeball the little bracket behind it, but when I did, things became more clear. The top of this little bracket was cracked, and I saw a circular mark of where a cylindrical spacer had been.

Gadzooks!

Was this it? Had I found the last piece of the cascade of failures? In addition to the broken and bent top bracket, this little bottom bracket had failed as well, but it was never repaired, and the spacer, stud, and nut were never reinstalled. Had that misaligned the regulator so that the limit adjuster at the top didn’t come to rest against the stop, which in turn made the motor keep spinning, which in turn caused the regulator to smack against the door bar that it was practically sitting against since the spacer wasn’t there?

Yeah, pretty much.

I pored through the realoem.com pages for the M coupe and found the sections for both the door and the regulator, but could not find any reference to the metal spacer. So: another trip to the hardware store. I found a threaded hexagonal spacer with M6 threads that seemed about the right length. As a test fit, I mounted it in place, putting a big washer on the bolt on the back to compensate for the bracket being broken at the top.

Just trying to give it some space, man.

Unfortunately, I couldn’t get the hole in the window regulator to align with the threaded hole in the new spacer. I attribute this to both the upper bracket being bent as well as to the holes in the fender washers likely not being where they originally were in the bracket.

I considered drilling a new hole in the regulator, but then I had a thought: Maybe, with the spacer in place and pushing the bottom of the regulator outward, it’s good enough. With the door open, I rolled the window up and checked the alignment of the Allen-head limit bolt with the stop plate. It was much better than before. I tightened the bolt a bit to bring it closer to the plate, then closed the door and rolled the window all the way up to the limit stop.

Silence.

Several things about my installation were intended to only be test fits, but with everything apparently working, I tightened all the regulator bolts and buttoned everything up.

I don’t consider this a permanent repair. The bracket will continue to flex, and that will be exacerbated because of the car’s automatic lowering and raising of the window whenever the door is opened, plus the fact that when the car sits, I disconnect the battery, so when I reconnect it, I have to reset the window limits by rolling them up and down again.

But it was enormously satisfying to get to the root cause of bent or broken brackets –> bad alignment –> upper stop not functioning –> window motor not shutting off that was apparently causing the banging.

A part of me thinks, “Sell it now before it breaks again.” However, despite my not driving the M coupe much, it’s too rare a part of my motley crew of vehicles for me to move along simply because of a window issue.

But I think I will re-engage my Millermatic welder so that next time,I can attack it with metal instead of J-B Weld.—Rob Siegel

Rob’s new book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.