The diesel-injection shop that’s cleaning and testing the injectors for my ’72 2002tii is backed up with work, so I still don’t have them back yet—and I can’t complete the head reassembly on Louie. So this week, let’s focus on a problem with a taillight.

I routinely describe my 2003 E39 530i stick sport as the best daily-driver BMW I’ve ever owned. This is especially surprising considering that my only other E39, the 1999 528iT sport wagon, was the worst daily-driver BMW I’ve ever owned. It was one of those cars that, when you bought it, you signed up for the repair-of-the-week plan, and no one told you.

Fortunately, that sort of constant “Good lord, what is it now?” routine has been almost completely absent from the 2003.

A few weeks ago, however, I found that the E39’s right rear directional bulb had become intermittent. I was alerted to it by the way the car changes to a rapid clicking sound when a bulb is out and you use the turn signal. I swapped the bulb, but it made no difference.

Then I found that messages were intermittently appearing on the instrument cluster saying that taillight and brake light were also out. A quick check of the right reverse light revealed that it was out as well.

Since every bulb in the right taillight assembly was affected, it seemed overwhelmingly likely to me that this was a ground issue. I hit the hazard switch to make the directionals flash, opened the trunk, and removed the battery cover to expose the back of the right rear taillight. I back-probed the pins on the connector with a multimeter and found that voltage was present. Then I set the multimeter to measure resistance, back-probed the pin for the brown wire, and checked the connection between that and chassis ground. The resistance measured essentially zero, indicating continuity.

So voltage and ground were definitely reaching the connector.

I then prodded the connector and the wires going into it. I found that by pushing on the brown ground wire, I could sometimes get the right directional and the other lights to come on. If there was a ground problem, it must be inside the connector or the taillight assembly.

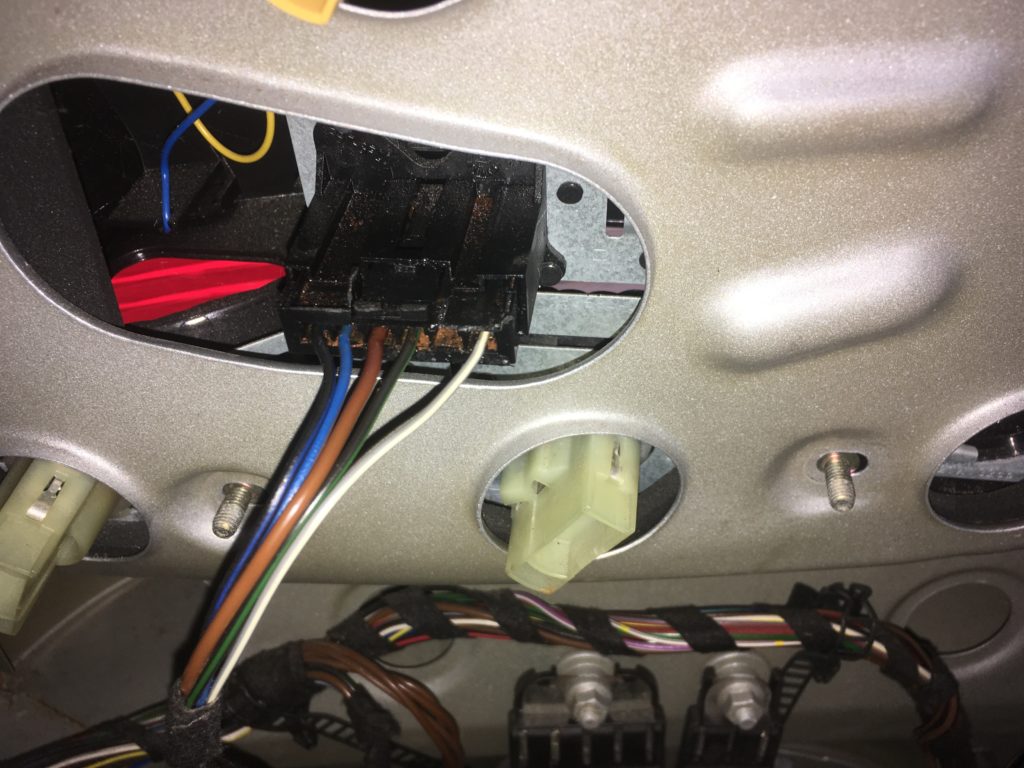

So I began to pull the assembly out of the car. I tried to remove the big rectangular connector plug going into the center, pressing down on the barbed release tab, but I couldn’t get it out.

Removing this plug was surprisingly difficult.

Finally, by a combination of lubricating with SiliKroil, prying with a screwdriver, and brute force, I got the connector out. I undid the four little 8-mm nuts holding the assembly in (okay, yeah, the photo above shows that I did that first), and removed the taillight assembly. With it out of the car, I could examine its basic structure.

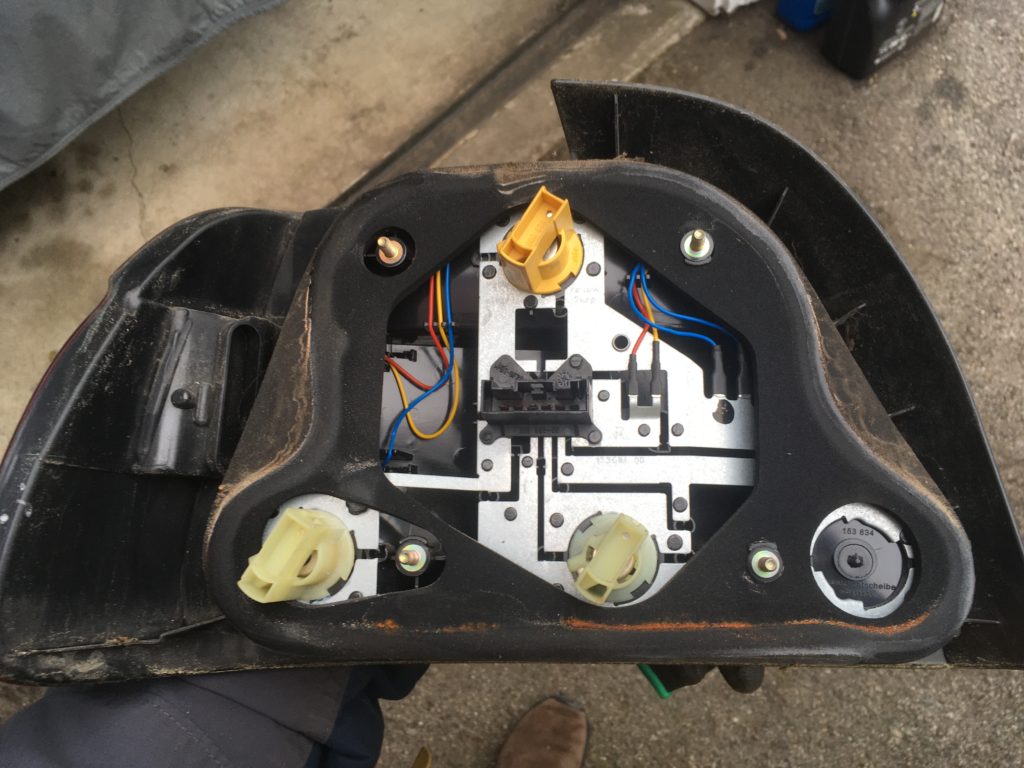

A series of aluminum plates and wires provide the electrical contact between the prongs on the connector and the terminals on the twist-in light sockets. This design has a certain amount of appeal, because the electrical contacts to the bulbs are part of the twist-in bulb-holder, not part of the taillight assembly, so if there’s an issue with intermittent bulb contact, the twist-in holder can simply be replaced.

I can’t tell you how many hours I’ve spent getting the taillights in the 3.0CSi and some of the other vintage cars to pass annual inspection because of intermittent bulb contact. When the metal tabs that make contact with the bulb are an integral part of the taillight assembly, as they are on the old cars, despite cleaning corrosion off them and bending them to increase the pressure against the bulb, getting the rear lights to work reliably has been surprisingly challenging.

Hmm…

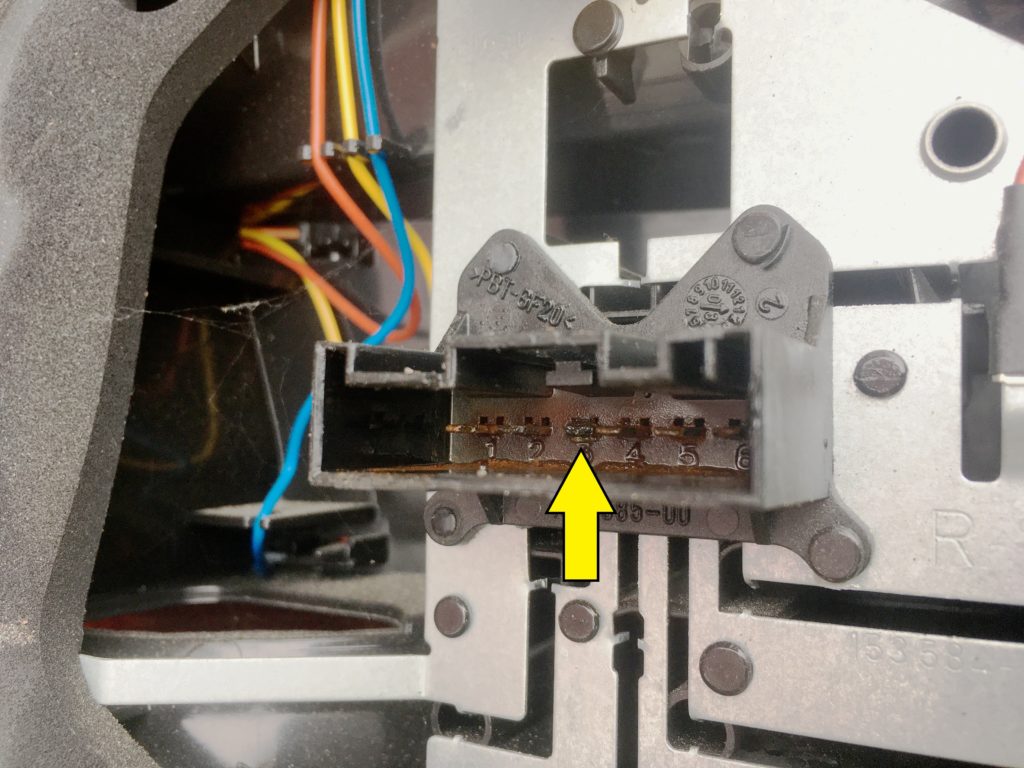

It wasn’t until I looked at the six-prong connector itself that I saw the problem: Prong #3, the one that receives the ground wire, was a rusty broken-off nub. This is probably why the plug was so difficult to pull out.

It also showcases a downside of the design: Those prongs are actually direct continuations of the metal plates. It’s not like you can just pull off the old connector and snap a new one on. Further, it was likely that the broken-off section of the prong was lodged in the crimp-on female part of the pin in the plug.

The smoking gun—I mean prong.

Upon seeing this, I tested the idea that everything would work if there was a good ground connection. I verified which one of the metal plates was the ground side of the directional bulb, took a test wire with an alligator clip on both ends, clipped one end to the plate and the other end to a convenient ground stud on the body of the car, hit the hazard switch, and—voilà!

Now certain that a bad ground was the root cause of the problem, my first inclination was to, well, hack it. Using the multimeter, it was easy to verify which of the metal plates connected to the ground sides of all three bulbs; all I needed to do was solder wires onto those three plates, join them to a single wire, and splice that into the brown wire that fed Prong #3—or connect it directly to ground. I could even make the jumper wire removable by splicing a pair of bullet connectors into it.

Then I did a little reading on E39 forums and found a post that said that Prong #6 is unused, and that the thing to do is carefully open up the plug, use a thin probe to push back the barbs that hold the pins in, slide the #3 and #6 pins out, and put the brown ground wire in the slot for #6. You still need to solder jumper wires onto the ground plates and connect them to #6, but I liked this solution.

Unfortunately, when I started down this path, two things happened. The first was that, using the multimeter, I couldn’t find where Prong #6 connected to any of the aluminum plates. This was odd, but it was rendered moot by the fact that while I was trying to hold the multimeter probe against Prong #6, the prong cracked in half—as #3 had—because it, too, was old and rusty.

Okay, so I guess it’s time for a new/used taillight assembly. I jumped on eBay and was a bit surprised that despite the ubiquity of the E39, used taillights with clear lenses for facelift cars like my 2003 were a bit more than taco money. Still, after I asked a seller to verify that the prongs in the connector weren’t rusty, for $60 shipped, a good used right rear taillight assembly was on the way.

While I was waiting for it to be delivered, I continued to drive the car, hyper-aware that I had no right rear directional. I really hate to add to the image of being another jerk in a BMW who doesn’t use his signals, especially while driving something like an E39, so whenever I had to make a right turn, I went old-school, rolling down my window and hand-signaling. (I think that this actually saved me from getting stopped. One evening at dusk, I was running errands in my hometown of Newton when a police car followed me closely for about a mile, possibly because my right brake and parking lights weren’t working, either. After I executed three right turns in a row while diligently hand-signaling, he headed off. I think he gave me the benefit of the doubt.)

When the replacement assembly arrived, I installed it, slid the plug into the connector, opened up the driver’s door, hit the hazard switch, walked back around to the rear to verify my handiwork, and—

The right taillight wasn’t flashing. Damn.

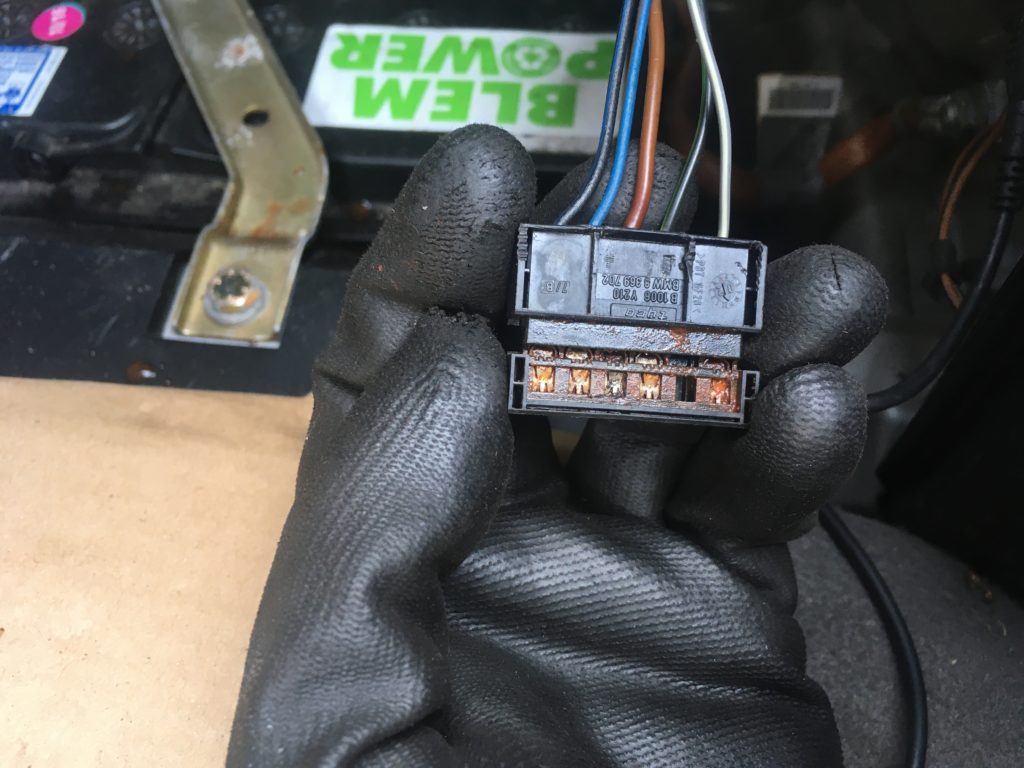

Then I realized that I’d forgotten all about the broken-off part of the prong still inside the crimped-on connectors inside the plug. I popped off the white plate hiding the connectors and tried to use a number of tools to release the little barbs, but couldn’t pull the brown wire and its connector out of the back.

Exposing the connectors didn’t help me slide #3 out.

So instead, I attacked the female side of the connector from the front with a metal pick and a tiny screwdriver. I never found and removed an identifiable chunk of the male prong that had broken off—it may have reduced itself to small fragments—but I verified that there was nothing blocking the opening. I again slid the plug into the six-prong connector socket, this time making sure that I could feel the prongs seat, and again hit the hazard switch.

Still nothing.

I did another round with the multimeter, checking both voltage and ground. This time I checked not by back-probing the pins, but on the metal plates themselves that delivered voltage and ground to the bulbs. Everything appeared to be fine. So why weren’t the lights coming on? Could the bulbs be bad?

I undid the yellow directional-bulb-holder from the old broken taillight and prepared to swap it for the one in the installed assembly. But when I removed that one and looked at it, I laughed out loud: There was no bulb in it!

I removed the others. There were no bulbs in any of them.

Yeah, that’s not going to be very bright.

I installed the old bulbs and holders, and everything worked fine. When I got back in the house, out of curiosity I looked at the eBay auction for the taillight I’d purchased. It clearly said, “No bulbs included.”

Not every satisfying repair is a months-long head rejuvenation on a 50-year-old BMW 2002tii. As I say over and over, these small repairs, where you fix them start to finish and know that they’re fixed, are incredibly satisfying to me. In a world where I can’t solve the Ukrainian crisis or fix health care, I can replace a taillight.

I just need to remember to check the bulbs.—Rob Siegel

Rob’s most recent book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.