I pulled the head off Louie, my ’72 2002tii, because it was cracked through one of the valve-cover bosses; in addition, the plugs in the ends of the rocker shafts had rattled out. From the look of the thick layer of varnish, the head had probably never been off the car, and with road trips scheduled for the spring, a fresh head gasket certainly made sense, reliability-wise.

In the past, when I’ve had a 2002 with a cracked head I’ve just tracked down another good used head, but ’72 tii’s with plastic intake plenums like Louie are unique because they have the early 121 head with 46-mm intake valves; the 121 head on non-tii’s have 44-mm intake valves. I’d previously tried to find a replacement big-valve 121 head, but couldn’t, so I yanked and dismantled the head and took it to my local machine shop, Century Automotive Machine in Waltham, Massachusetts, for cleaning and evaluation. Unfortunately, they don’t do crack repair, so I had to find another shop to fix the crack.

That amount of varnish generally indicates that if the head had ever been off the car, it was probably when ABBA was still at the top of the charts.

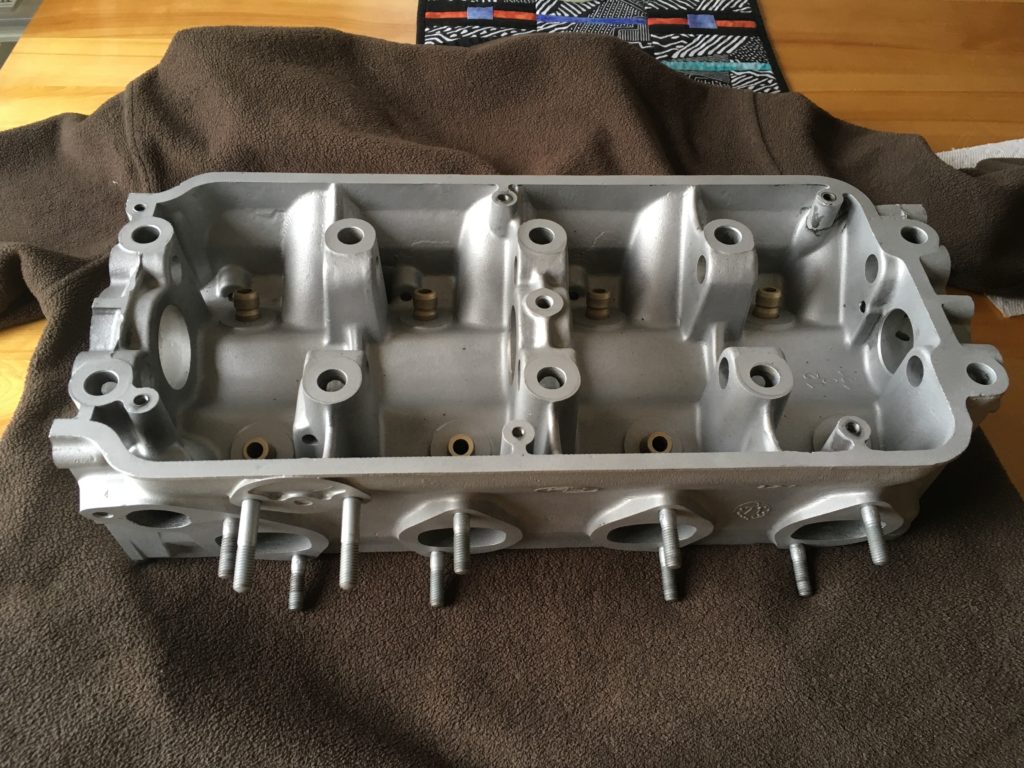

Century pulled the valves and examined them and the valve guides, deemed them all fine, hot-tanked and glass-beaded the head, checked for other cracks, and checked for straightness. They found a warp of a few thousandths of an inch, nothing that couldn’t be planed off. I’ve had 2002 heads so warped that the cam wouldn’t slide back into its journals in the head. This one had no such issue.

Mmm, fresh!

But there was still the matter of the crack, which was the main reason I’d pulled the head. It extended through the boss holding the stud at the lower rear of the valve cover. Five years ago, when I bought the car and prepared to drive it home from Louisville, the crack made it so the valve cover wouldn’t seal; tightening the nut on the stud just made the crack yawn open. Looking at it closely, I could see where blue RTV had been squirted in, in an attempt to seal the crack (even though at the time, that’s not where it was leaking), so clearly a previous owner knew about it. It seems likely that the cost of replacing the cracked head was the reason the car had been parked for a decade.

I first discovered the crack five years ago.

To get the car home from Louisville, I sealed the valve cover with “The Right Stuff” by Permatex. I continued to drive the car that way for two years. But then, when I was driving the car home in 2019 after its stay at the 2002 Icon exhibit at the BMW CCA Foundation, oil began to drip onto the exhaust manifold from near the #4 spark plug. Although I couldn’t see clear evidence of a crack on the outside, it was obvious from the location of the drip that the leak was coming from the cracked boss. I camped out for a few hours in Lance White’s shop in Cincinnati, and with advice from White’s late, great mechanic Safet Hatic, sealed the crack with J-B Weld (I used the KwikWeld), waited a few hours, and then drove home.

My on-the-road application of J-B Weld to the inside portion of the crack.

The inside portion of the crack after the head was removed and cleaned, and the excess J-B Weld was bead-blasted off.

I couldn’t see the outside portion of the crack with my naked eyes. This was my photographing it as best I could by sticking my phone where I couldn’t stick my head. It didn’t look like a crack, but that’s where the oil was seeping out of. I cleaned it and slathered J-B Weld into it.

The J-B Weld on the outside of the head after it was cleaned.

The J-B Weld repair held so well that I not only made it home, but continued to drive the car like that for the next three years. Still, I wasn’t entirely comfortable treating it as a permanent repair, and with spring road trips on the horizon, well, here we are.

I searched online and called around to find a local machine shop that could repair the crack. I found three and sent them all photos. I selected Jon Andruk at Circle Performance in Berkeley, Massachusetts, due to the combination of a recommendation from a friend, price, proximity, responsiveness, and liking his email and phone answers. For $240, Andruk did the “It won’t necessarily be pretty” repair.

My fear that my having shoveled J-B Weld into the crack in order to get home would come back to bite me turned out to be well founded: Andruk told me that in order to properly seal it, he’d need to pull off the cracked boss, clean out the J-B Weld, and fabricate something new. He also said that what I saw under the J-B Weld on the outside of the head wasn’t a crack but a casting defect in the head. So it’s likely that the crack from the inside permeated through until it hit the casting defect, at which point oil spilled onto the exhaust manifold.

The rebuilt boss won’t win any beauty awards, but if it works, I’m happy.

The repaired outside corner of the head covers a casting defect.

From there I took the head back to Century, my local machine shop. At some point—I believe in the early 1980s—updated valve guides and seals became available for these M10 heads to help lessen or eliminate the very common problem of oil burning when you let off the throttle, and the standard advice is that if the head is off, it’s worth installing them.

I take a very practical and cost-effective approach to this sort of thing. If the engine is exhibiting trailing-throttle oil-burning, and if the machine shop finds worn guides, then yes, I locate the updated guides and seals and have the machine shop install them. But if the shop says the guides aren’t worn and if the car isn’t blowing oil when you let off the gas, then I hold costs down by not updating the guides. Since the machinist at Century said that all my valves and guides were fine, I replaced only the seals. You can make your own choices on your engine.

Although I had a full Reinz head-gasket set in the garage, I wanted to be certain that I had a set of high-quality old-style valve-stem seals. I found a set of Elring seals on Rockauto for about ten bucks, shipped.

I paid Century to do a few other things. The clean head looked so nice that I had them hot-tank, glass-bead, and paint the valve cover. They also cleaned and polished the camshaft and rocker-arm surfaces. (I’m replacing the damaged rocker shafts but re-using the original rocker arms, since the fit with the new rocker shafts seems fine. Again, you can make your own choices on your car.) All told, the bill was a bit higher than the usual $400 for head R&R.

I’m probably going to regret the mint-looking valve cover; since the rest of the engine compartment looks like hell, it’ll look even worse now, and I’m just not the kind of guy who cleans and sandblasts and paints and details engine compartments. But who know? Old dogs, new tricks, and all that.

Yum.

Between the bills from the two machine shops, the total was about $700. While that’s certainly higher than I’m used to for a just-a-valve-job or a just-a-head-gasket decapitation, other than the extravagance of getting the valve cover cleaned and painted, I’m not sure that there was much other money to be saved.

Next week I’ll dive into the reassembly of the valvetrain.—Rob Siegel

Rob’s new book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.