Back in 2018, BMW unveiled the world’s first 3D-printed pneumatic material. Created using a process called liquid-printing in the Massachusetts Institute of Technology’s Self-Assembly Lab, the material was billed as being highly adaptable and able to self-transform, with strong potential for use in automotive applications, specifically within passenger compartments. Now, after the passage of a few years to further mature the technology, BMW’s venture capital arm, BMW i Ventures, has participated in a seed financing round of Rapid Liquid Print, which has an exclusive license from MIT for liquid-printing technology.

“RLP’s breakthrough technology is disrupting the 3D-printing space by enabling the rapid printing of elastomeric structures of any size and complexity,” said Marcus Behrendt, partner and CEO at BMW i Ventures. “With BMW i Ventures’ support, the RLP team can continue demonstrating its commitment to creating high quality, low-cost elastomer products.”

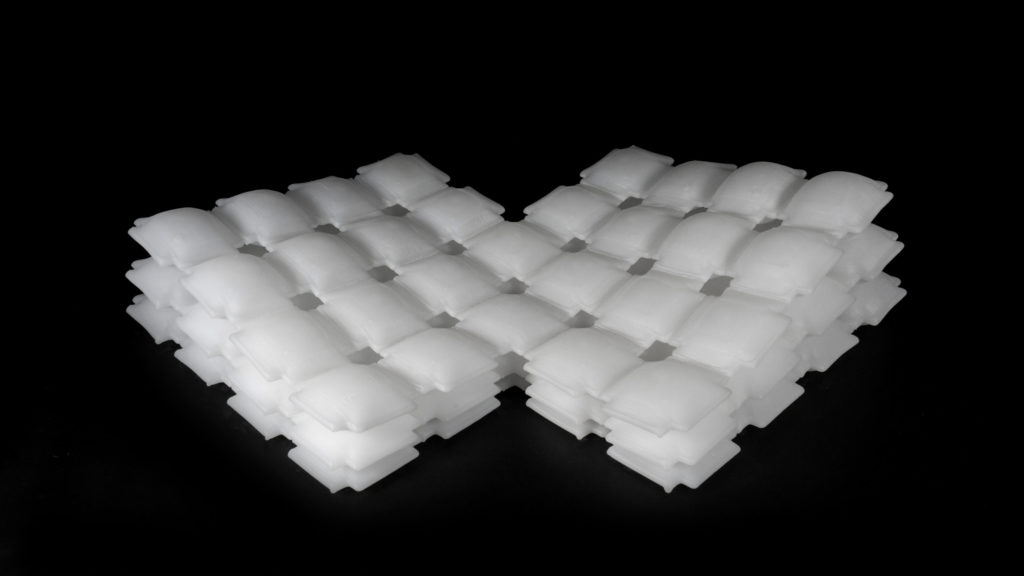

Rapid Liquid Print’s liquid-printing technology is described as revolutionary, and relies what’s initially extruded as gel to create elastomeric materials used within the automotive industry such as rubber, silicone, and foam. The end products are soft and flexible, and require little in the way of retooling or post-process treatment. Objects created using liquid-printing are initially drawn in a three-dimensional gel suspension, not unlike conventional 3D-printing, but come with the benefits of faster production times, improved material quality, larger production volume, and large-scale object applications.

“We’ve spent years perfecting our technology and building a product that solves the pain points the 3D-printing industry has faced. RLP removes limits on design, can print large-scale and multiple objects at once, and is faster than any other solution currently on the market,” said RLP Founder & CEO Schendy Kernizan. “With this funding from BMW i Ventures and MM Catalyst Fund we will accelerate our ability to offer a wide variety of solutions to a broader market.”

Funding from the round of seed financing will be used to help RLP further develop their printing solutions, expand with existing customers, and work with new clients with different applications and materials.

The BMW i Ventures funding of RLP is not the only interesting interior-focused investment the company has recently made. Back in July, the venture capital fund invested in Natural Fiber Welding, a Peoria, Illinois-based startup focused on creating all-natural, plastic-free alternatives to traditional materials like leather, foam, and textiles.—Alex Tock

[Photos courtesy BMW AG.]