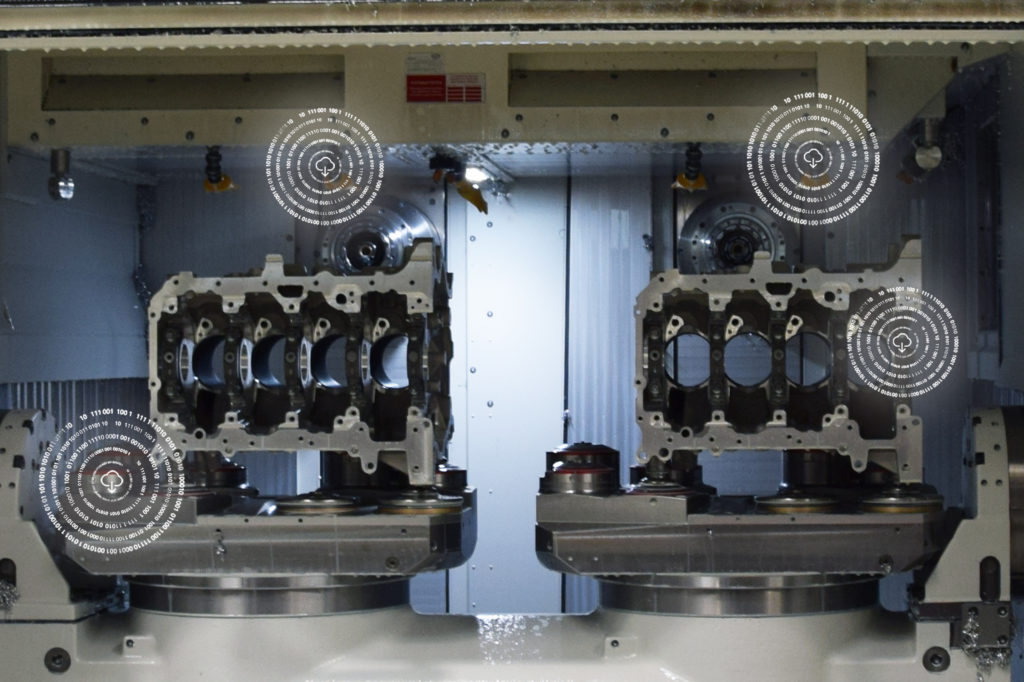

Similar to how our BMWs were designed to adhere to a maintenance schedule with planned servicing, the machines and tooling used to manufacture them must also be kept up. With thousands of machines, each with a multitude of moving parts, spread across a global decentralized production network, the magnitude of such a task becomes clear. The solution lies within the array of sensors within each machine, that feed a steady, uninterrupted stream of data to the cloud, which is then analyzed to predict when maintenance and/or repairs are required.

The benefits yielded by the realtime collection of data from manufacturing operations are multifold. In addition to enabling BMW to more accurately forecast when a failure might occur and potentially mitigate them all together, predictive maintenance allows for greater avoidance of unplanned downtime due to repairs when integrated with AI. It also helps to prevent the unnecessary early replacement of parts and components which are still within their service life, and acts as an early-warning system for when something might be approaching a failure. In short, predictive maintenance lets BMW to perform maintenance and repairs to its production systems based on their actual condition as opposed to an educated guess, and lets the automaker integrate servicing into pre-scheduled downtime.

Thanks to BMW’s position as a global leader in production and manufacturing, and the company’s heavy reliance on technology and data to gain insight, predictive maintenance is currently being rolled out across the automaker’s global decentralized production network. The predictive maintenance system itself is globally accessible even though its tied in with individual machines on factory floors, and is described as highly scalable, allowing for the implementation of new application scenarios and existing solutions to be quickly integrated. Predictive maintenance is also said to be a key component in the BMW Group’s sustainability goals, as it allows for extended running times and prolonged service life of tools and machine thanks to more accurately targeting repairs and minimizing unnecessary costs.

The range of applications for predictive maintenance is varied and diverse, and stretches across numerous aspects of vehicle production. In the bodyshops of BMW’s production plants, welding guns, which perform approximately 15,000 spot welds each per day, provide important insights. Data from welding guns around the world is collected by specially-developed software, sent to the cloud, and then analyzed with algorithms. The same thing is happening with the control units of the conveyer systems at BMW Group Plant Regensburg, for example, which feed a realtime data stream which includes electrical currents, temperatures, and locations to the cloud for constant analysis. The data enables specialists to identify the position, condition, and what’s happening with every convey element at any given time, and and predictive AI models use the data to detect anomalies and locate problems, potentially before they happen.

BMW’s use of predictive maintenance comes as no surprise given the automaker’s investments and partnerships with regard to the use of AI as it applies to disciplines such as production, painting, and prototyping.—Alex Tock

[Photos courtesy BMW AG.]