Anyone who’s ever done any degree of paintwork knows that the quality of the finished product depends heavily on preparation. This can take many forms, but is most often centered around the item, panel, or vehicle that is to be painted, and the environment in which the work is being carried out. We all wish we could work in the sort of clean rooms and climate-controlled setups that are used by semiconductor manufacturers and automakers, but the truth is that many of us are simply happy to have a small shed or spray booth in which to refinish things, if we’re so lucky.

Since at least the 1980s (and rather famously during the GM10 debacle under CEO Roger B. Smith), auto manufacturers have been using robots to paint cars. The adoption of automated paint application did wonders for quality, which had been rather hit and miss in relation to exterior finishes up until that point. Now however, BMW is looking to take things a step further, by applying artificial intelligence and machine learning to the paint process, and more specifically dust control.

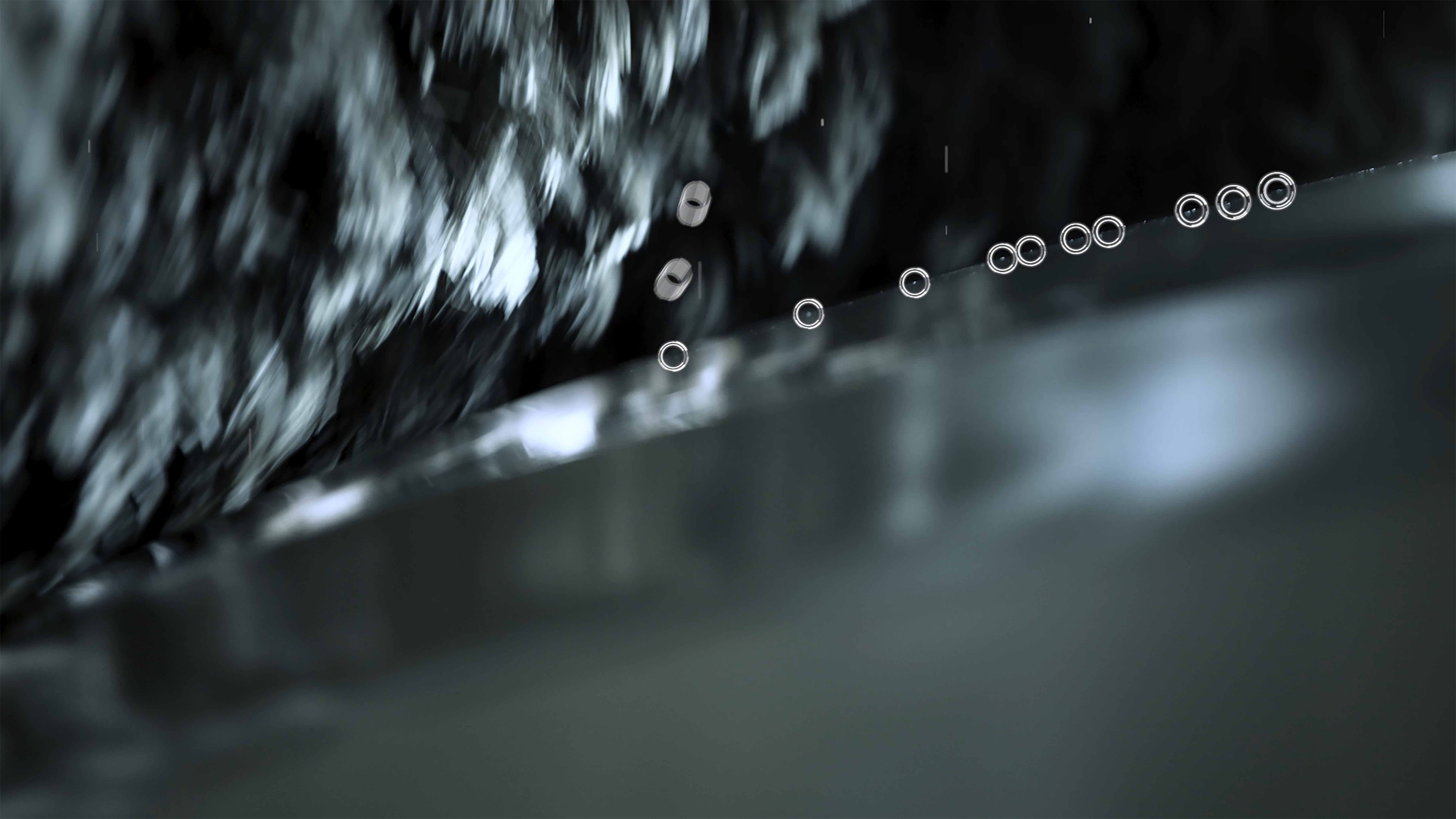

Dust and other environmental contaminants and pollutants are the enemy of a quality paint finish, but are impossible to completely eliminate. Even in the cleanest environments, dust particles find their way in, and can contaminate a freshly-applied coat of paint, rendering the finished product unable to meet quality standards. BMW, like plenty of other volume automakers, employs a highly-controlled precision process. Dust mitigation is an integral component, but even using the absolute best filters which are changed at strict intervals leaves more to be desired.

In BMW’s latest practical application of AI and machine learning to the production process, troves of data are being run through algorithms to compare live results with optimal conditions. The algorithm currently in development monitors more than 160 different datapoint relating to a vehicle’s body, and can accurately predict paint quality to a high degree of accuracy. It’s also being used to more precisely pinpoint when to change the filters used to maintain cleanliness in paint spray booths and dryers, and can be used in conjunction with other analytical tools to further increase quality. One example is BMW’s use of Ostrich feathers to remover dust particles from car bodies prior to the application of paint, and this is another area where BMW’s new machine learning tools can be used to further improve finished quality.

In a statement published last week, BMW says it has filed for several patents in relation to the new technological developments. Although it’s merely a pilot program confined confined to BMW’s main Munich plant right now, those with specific knowledge say that it could soon be rolled out to other production facilities.—Alex Tock

[Photos courtesy BMW AG.]