The BMW Group’s venture capital arm, BMW i Ventures, is investing Peoria, Illinois-based Natural Fiber Welding, a firm which specializes in creating all-natural, plastic-free alternatives to traditional materials like leather, foam, and textiles. The investment is aimed at enabling the company to scale from small-batch processing to commercial-scale roll-to-roll production, and opens the door for close cooperation with BMW, which has already begun.

The applications of Natural Fiber Welding’s products are obvious when looking at the interior materials of models like the BMW i3, i8, and iX, which use recycled elements. Natural Fiber Welding has developed innovative technologies to produce materials which replace petroleum-based components like synthetic leather, or as BMW markets it, Sensatec. The leather alternative created by Natural Fiber Welding is called Mirum, but it’s not the only material the company has developed.

“Natural Fiber Welding has developed an innovative process of converting plants into all-natural, 100% recyclable material that mimic all the properties of traditional leather, yarns, and foams. Having a scalable, cost-competitive alternative to leather with premium qualities is key to further advancing the decarbonization of the automotive industry,” said Kasper Sage, managing partner at BMW i Ventures.

In addition to providing funding via BMW i Ventures, the BMW Group intends to form a strategic partnership with Natural Fiber Welding to allow the automaker to achieve its ambitious sustainability goals. Efforts like this include greater use of recycled materials, but the need to maintain quality is ever-present.

“BMW i Ventures’ commitment to high-performance companies across the manufacturing and transportation sector makes them an excellent investor and partner for NFW,” said Luke Haverhals, founder, and CEO at NFW. “We are honored to have their support as we continue to expand into new markets, like automotive, where all-natural, performance materials can have a huge impact in decarbonizing and creating a truly sustainable future.”

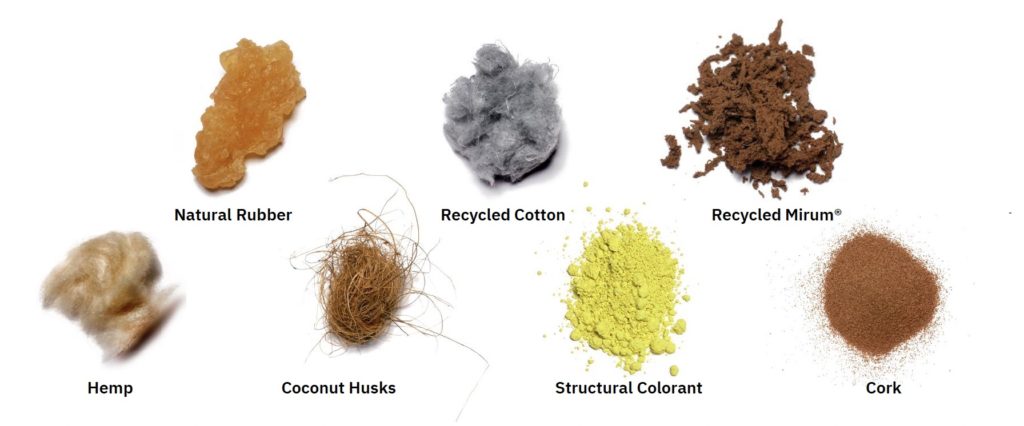

Some of the underlying materials that Natural Fiber Welding works with are captured in the photo below. If BMW’s plans come to fruition, synthetic leather and textiles produced by Natural Fiber Welding could very well end up in the BMW models of the not-too-distant future.—Alex Tock

[Photos courtesy BMW AG.]