As the market for electric vehicles grows, so too does demand for the raw materials which make up their construction, more specifically the elements used in their batteries and electric motors. BMW’s fifth-generation eDrive architecture doesn’t require any rare-earth metals, which are difficult and controversial to source, and now, the company is working to source lithium for battery cells in the most sustainable way feasible.

BMW entered into an agreement to source lithium from Australian mines back in 2019, but has recently expanded to work with U.S.-based Livent to extract the material from Argentina. Lithium is found in brine deposits which surround salt lakes in the border region between Argentina, Bolivia, and Chile. Instead of the conventional practice of pumping brine into large evaporation basins to extract lithium, Livent has developed a process which minimizes the use of evaporation with an emphasis on sustainable water use and minimizing the impact on local ecosystems. Most of the brine used for extraction is also returned back to the surrounding habitat and is not evaporated.

BMW says the contract is valued at around 285,000,000 €, or approximately $337,000,000, and that Livent will supply lithium directly to BMW Group battery manufacturers starting in 2022.

“Lithium is one of the key raw materials for electromobility. By sourcing lithium from a second supplier, we are securing requirements for production of our current fifth generation of battery cells. At the same time, we are making ourselves technologically, geographically, and geopolitically less dependent on individual suppliers,” explained Dr Andreas Wendt, member of the Board of Management of BMW AG responsible for purchasing and supplier network.

In late 2020, BMW and German multinational chemical company BASF commissioned a study for the scientific analysis of the water use associated with different lithium mining methods in South America from the University of Alaska Anchorage and University of Massachusetts Amherst. The intent of the study is to investigate how lithium mining effects local water resources and surrounding habitats and ecosystems, and to further expand the understanding of how fresh water and lithium brine aquifers interact. The study will also examine and evaluate different technologies and processes to provide a basis for assessing sustainable lithium extraction. Like BMW’s agreement with Livent, the sustainable lithium mining study will yield results beginning in 2022.

BMW also became the first automaker to join the Initiative for Responsible Mining Assurance (IRMA) when it became a member in 2020. The BMW Group plans to adopt IRMA-developed standards in regard to the responsible sourcing and extraction of raw materials in the future, and Livent has also become a pending member, making it one of the first lithium mining companies to join.

BMW’s efforts for the sustainable sourcing of lithium dovetail with the automaker’s efforts to develop recyclable battery cells.—Alex Tock

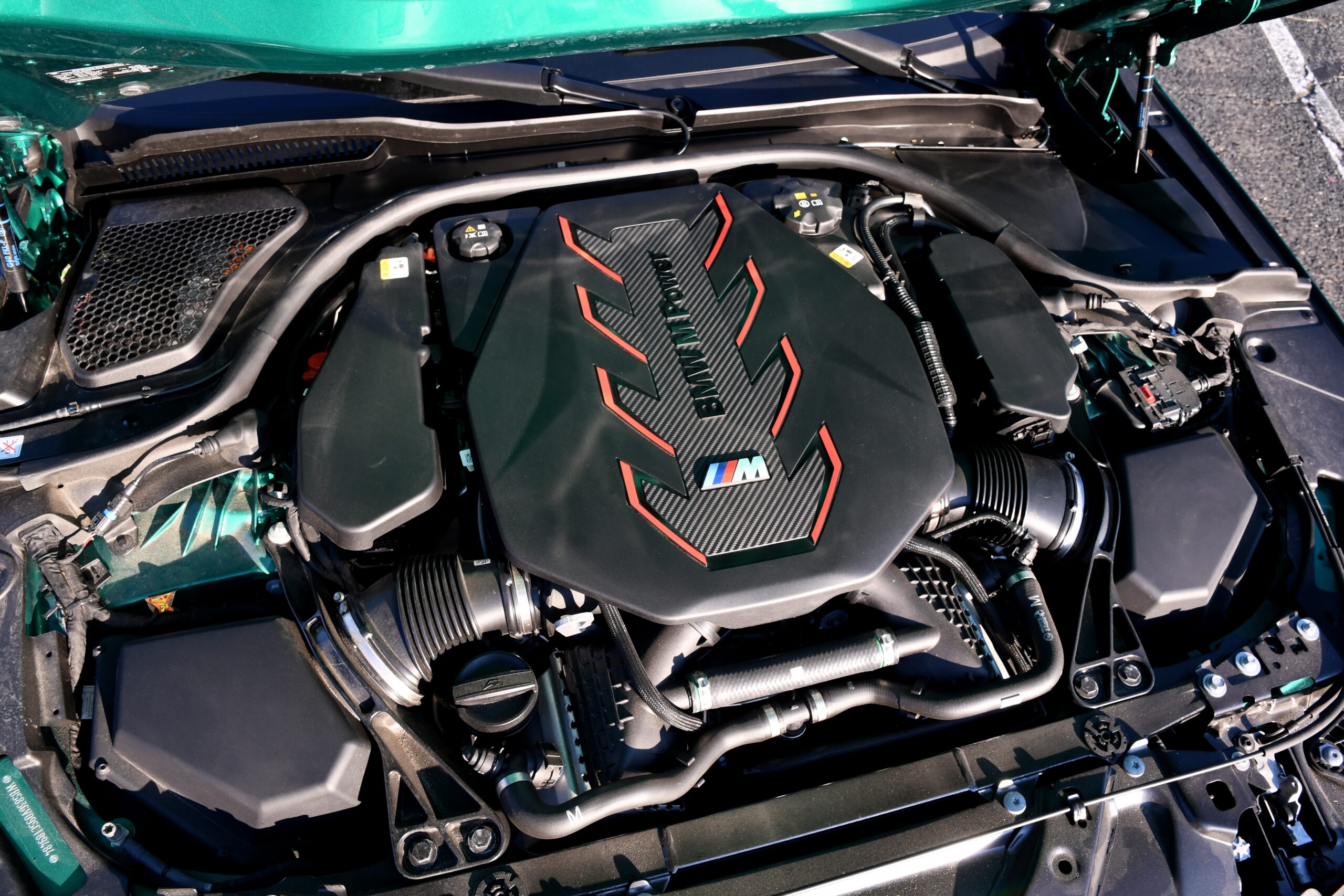

[Photos courtesy BMW AG.]