BMW’s venture capital fund, i Ventures, is investing in a startup that is working to transform the production of steel. The company is called Boston Metal, and was founded in 2012 by a Massachusetts Institute of Technology professor specializing in materials chemistry. The promising technological concept is referred to as molten oxide electrolysis (MOE) and has the potential to greatly reduce greenhouse gas emissions from the steel production process, by virtually eliminating carbon dioxide from the equation. Steel made using MOE has yet to be produced on any kind of industrial scale, but the possibilities and benefits have been recognized by the likes of the NASA and another venture capital firm funded by Bill Gates, and could disrupt the steel industry, which is said to be responsible for around 8% of global annual carbon dioxide emissions.

The investment is part of a long-term strategy at BMW to become as environmentally sustainable as possible. The company already appeared on the Dow Jones Sustainability Index in 2020 as the most sustainable automaker, but has ambitions beyond simply producing and selling electric vehicles, and is working to ensure that nearly every aspect of its existence and operations is as environmentally neutral as possible. Recent efforts include the use of sustainable packaging materials and hydroelectric energy for production of the upcoming i4 and iX, while broader endeavors such as sustainable battery cells are also on the agenda. Last month, BMW also began sourcing a sizable portion of its aluminum from a supplier using solar power to produce it.

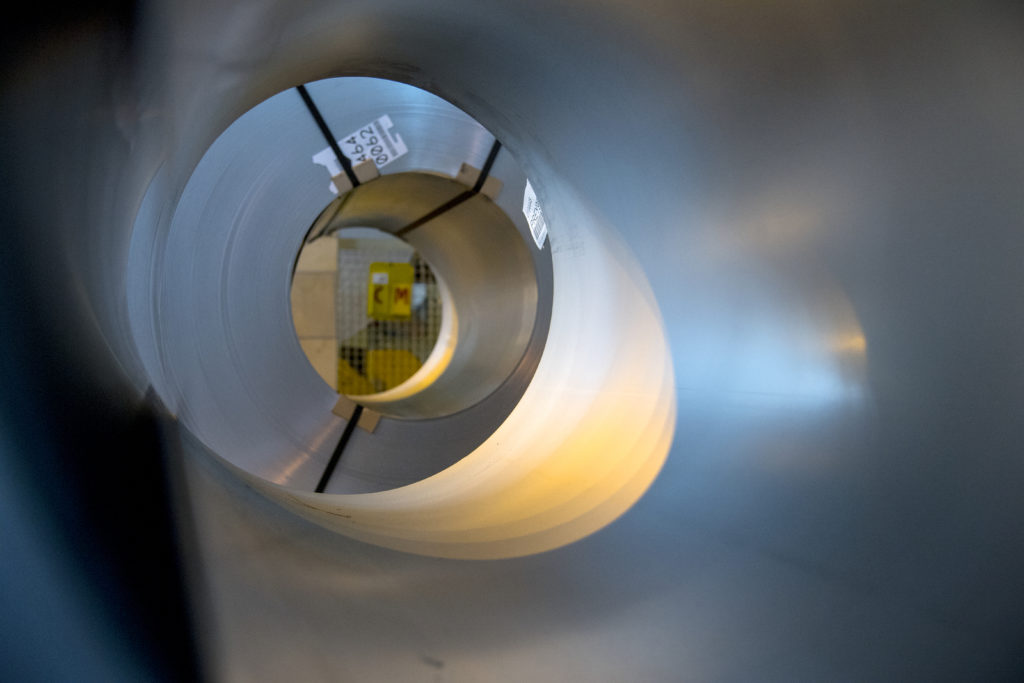

Although the entire automotive industry is embracing electric propulsion, the vast majority of vehicles are still primarily made of steel and other metal alloys. The motorsport-inspired carbon-fiber substructure of BMWs like the i3 and i8 remains impressive several years on, but high production costs and a lack of uniformity between the broader vehicle lineup were likely motivating factors when the modular CLAR and FAAR platforms were chosen as their successor a few years back.

Conventional steel production relies on the use of blast furnaces, and the steelmaking process hasn’t fundamentally changed over the last half century, with the oxygen converter process and electric arc furnace method being the most common. Boston Metal’s molten oxide electrolysis method instead uses what’s called an electrolysis cell, which produces pig iron that is later refined and processed into steel, thus achieving the same end result without the footprint of a blast furnace. BMW adds that, if energy from renewable sources is used to power the process—something the automaker already requires of its steel suppliers—steel production can be free from carbon emissions. As noted above, BMW also recently signed a contract to source CelestiAL aluminum, which is produced exclusively using solar power.

Boston Metal has previously caught the attention of Bill Gates, and was backed by the Breakthrough Energy Ventures fund, which he finances. In January, the startup raised $50,000,000 to expand its operations. BMW offers further detail into how it plans to “decarbonize” heavy metal through its investment in Boston Metal on the BMW i Ventures news page.—Alex Tock

[Photos courtesy BMW AG.]