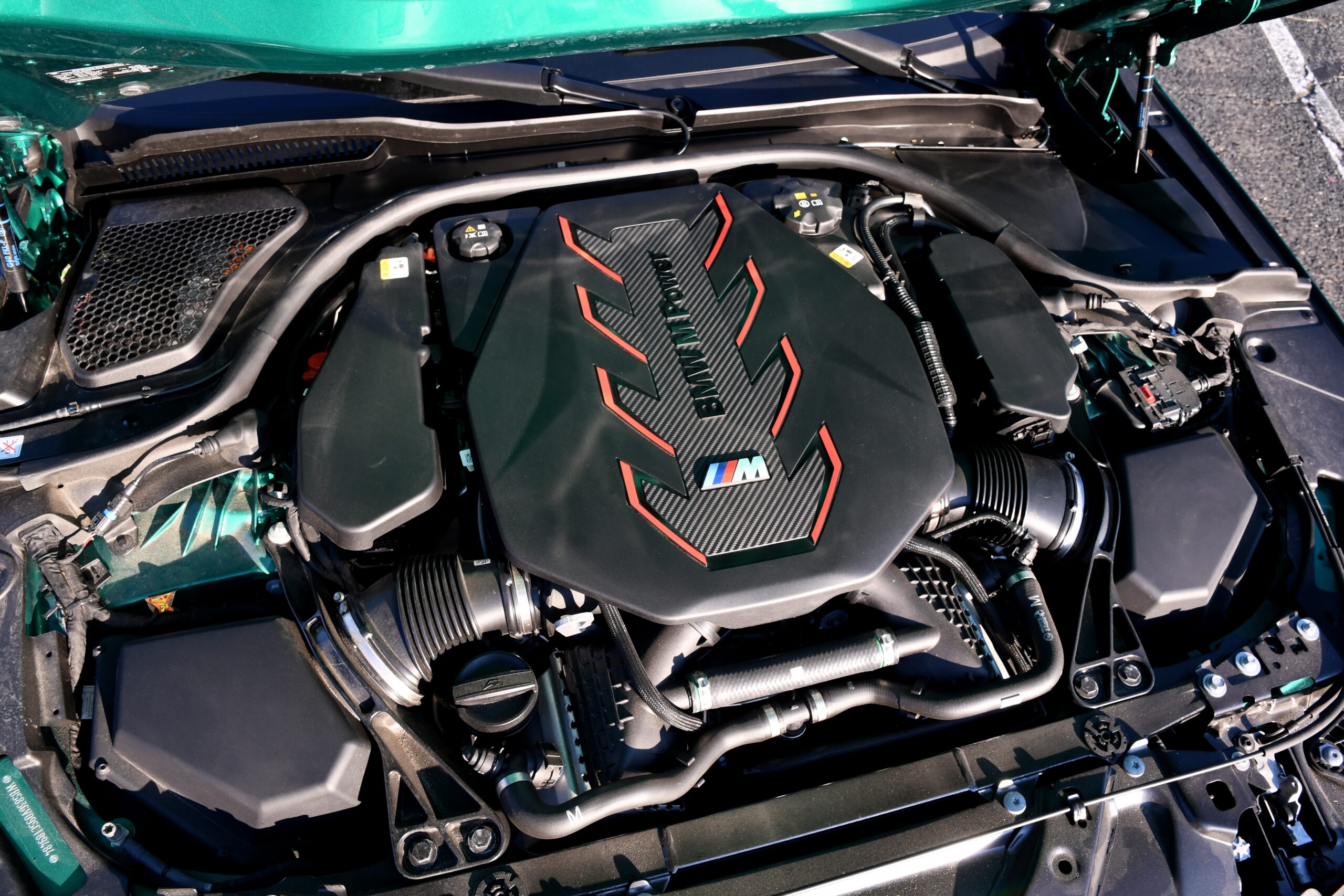

BMW is investing €400,000,000 in a new vehicle assembly line at the company’s headquarters in Munich, Germany. The project is an ambitious one, which is scheduled to see completion in 2026. Slated to take the place of the existing engine production line, which is responsible for manufacturing the four-, six-, eight-, and twelve-cylinder engines which power the current BMW fleet, the new line will be focused on building vehicles based on an updated cluster architecture modular platform. Engine production will be moved to or ramped up in sites outside of Germany, including Steyr, Austria, and BMW Group Plant Hams Hall in the U.K., the latter of which already builds BMW engines.

The plan has been highlighted by Manfred Schoch, Deputy Chairman of the Supervisory Board and Chairman of the European and General Works Council of BMW A.G., who said, “The decision to build a new assembly at our almost 100-year-old Munich plant shows that transformation can secure, and even create, industrial jobs in the heart of the city—if it is approached strategically, and with courage. This decision provides a model for successful transformation in the German industry.” The first minute of this video, which chronicles development of BMW’s iX, may help to provide further context.

Although it’s not clear which BMW models will be made on the new line in Munich, engine production is scheduled to be relocated from the main BMW plant in stages no later than 2024. It’s all part of BMW’s transformation from a producer of internal-combustion-powered vehicles to the mobility entity of the future. At the same time that internal combustion engine production is being shuffled, BMW is investing heavily in many aspects of electro-mobility, one example of which is the E-Drive Competence Center in Dingolfing, which will see its staff double in size from 1,000 to 2,000. BMW Group Plants Leipzig and Regensburg, meanwhile, are in the midst of preparing to produce battery modules and the high-voltage batteries which comprise them, starting next year. In addition to building engines in Steyr, BMW is also increasing production of E-Drive casings in the plant there.

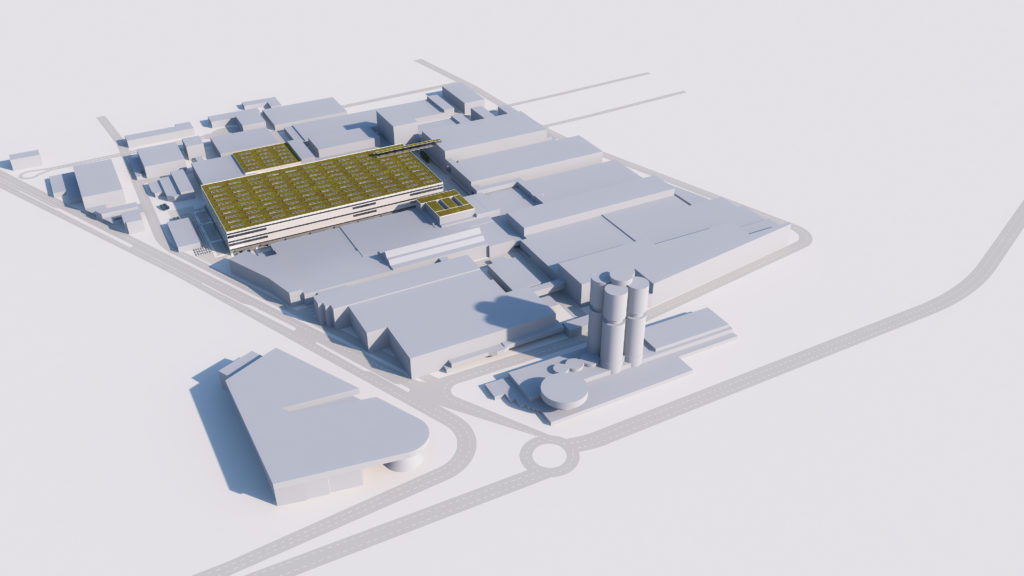

One week prior to the announcement of the new vehicle assembly line in Munich, the BMW Group completed construction of its new Driving Simulation Center. The need for simulated driving in the conception and development process of a vehicle may not be immediately apparent, but it’s become a necessity in a world in which vehicles drive themselves. It may sound like a contradiction, but the purpose of a vehicle is still to enhance the mobility of its users and passengers, and the driving experience has become increasingly more important as auto manufacturers blur the lines between driving itself, and automation.

The first static driving simulators were used in the development of BMW models starting in the early 1990s. By 2006, the automaker had invested in its first dynamic simulator, which was supplemented by another in 2016 at the BMW Group’s Research and Technology House in Garching. The new Driving Simulation Center in Munich boasts a footprint of over 120,000 square feet, and is home to fourteen driving simulators. The simulators will be used to aid in every part of the vehicle production process, from concept development, to prototype testing, and finally, pre-production shakedowns. BMW says the Simulation Center will aid in the creation of driver-centric vehicles, including how they behave in the every day situations we find ourselves, like sitting in rush hour traffic.

Of the fourteen simulators onsite, two stand out. The first is the high-fidelity driving simulator, which has a development focus centered on driving in challenging situations, such as navigating through an urban area in dense traffic. The high-fidelity driving simulator can provide an acceleration experience comparable to that of the BMW M3, with a zero-to-60 time around 4.2 seconds (or a force of 0.65 g), has moving mass of around 83 tons, a motion area of 4,300 square-feet and 32 feet of vertical movement, and uses 6.5 megawatts of electricity at its peak. There’s also the high-dynamic driving simulator, which is focused on recreating the most intense, white-knuckle moments behind the wheel. The high-dynamic unit can simulate acceleration on par with the BMW iFE.20 Formula E racer, or zero-to-60 in less than 2.8 seconds (equivalent to one g), but uses less than half the energy at its peak, or around three megawatts.—Alex Tock

[Photos courtesy BMW AG.]