Last week, I trouble-shot the problem of Hampton, my 48,000-mile ’73 2002, not wanting to prime its fuel system after sitting all winter. I determined that the mechanical fuel pump was fine, and that the problem was that a metal canister-style filter had been placed on the inlet side of the fuel pump, creating an air pocket that the pump couldn’t suck out. This created a bootstrapping problem wherein, after the car had sat all winter and there was no fuel in the lines or gas left in the float bowl, the engine wouldn’t start, but once I got it started via starting fluid or splicing in an electric fuel pump, then, with the engine running, the higher rpm would make the pump run a lot faster, which would pump gas and keep the float bowl filled.

I am fairly confident in this diagnosis, since I repeated the test several times, and the results were consistent. Filter before fuel pump: no pumping while cranking. Filter removed or after fuel pump: pumping while cranking.

However, as I said in the piece, I freely admit that your mileage may vary. You may have a filter on the inlet side of your fuel pump and it may work just fine. And I may well have a combination of a weak starter motor, a fuel pump with an old rubber diaphragm that’s lost some of its elasticity, and perhaps a pinhole leak I haven’t found that’s sucking air.

And that brings us to the following. The day after I thought I’d solved the problem, the car was difficult to start—not crank-it-forever-and-it-ignores-you-like-it-isn’t-getting-fuel difficult, but harder than it should’ve been. And then I recalled that I’d had this same problem immediately after I bought and started the car, as well as last fall after my first round of sorting, and that was odd. It makes perfect sense that if there’s no fuel in the float bowl, a carbureted car won’t start until there is, but once it’s primed, a few stabs of the accelerator pedal should squirt raw gas down the throat and get it to fire up.

If you don’t know, many carburetors have integrated into them an accelerator pump with a little rubber diaphragm similar to the one that’s in the fuel pump (you can think of them as the “other” mechanical fuel pump). It’s connected to the throttle linkage. When you hit the accelerator, it tugs on a lever which moves the diaphragm and creates a pressure differential. If that differential is large enough (meaning if you move the gas pedal quickly enough), it’ll goose a bit of gas into the channel that leads to the nozzle that hangs over the carburetor throat. This is why, on a carbureted car, you typically stab the gas pedal a few times prior to starting it if it’s cold. (Interestingly, the Stromberg carbs on my Lotus Europa, and the similar SU carbs, don’t have an accelerator pump, something I learned when I was trying to start the just-resurrected car.)

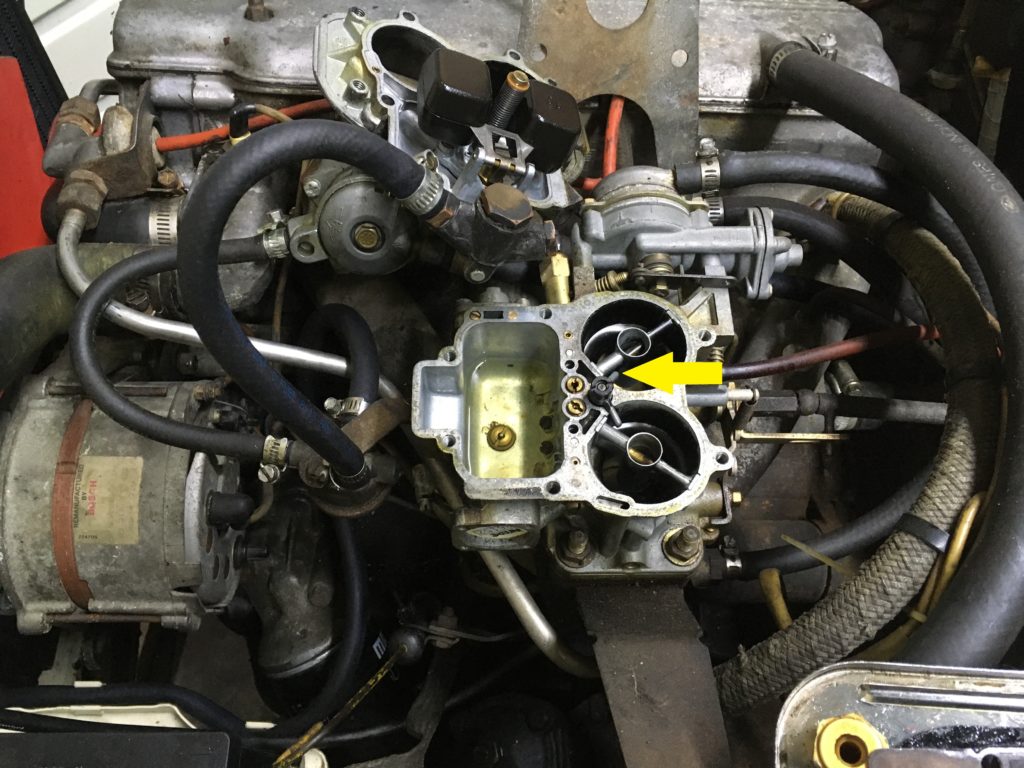

The accelerator pump nestled under the right side of the Weber 32/36 DGV: Behind those four screws is a rubber diaphragm. You can see the little piece of metal in the center that’s connected to the pump linkage.

I took a flashlight and peered down the throat of Hampton’s Weber while I snapped the linkage a few times. Sure enough, no fuel was being squirted. Gotcha. (As a mechanic, you live for the “gotcha.” At least I do.)

The yellow arrow is pointing to the pump nozzle hanging over the carburetor throat. Fuel should squirt out of it when you blip the gas pedal. It wasn’t.

When this happens, it can really only be due to three things. Either the portion of the linkage that runs to the accelerator pump has been disconnected, the pump diaphragm is torn or inelastic, or there’s some internal obstruction. I quickly checked the first by reaching under the Weber, moving the main linkage, and verifying that it tugged the little metal bits that connect to the accelerator pump. So that left the other two.

Now, I’ve resurrected many long-dead cars. If they’ve been sitting for a decade like Hampton, or for 40 years like the Lotus, there’s zero doubt that the fuel system needs to be inspected and cleaned. When I bought Hampton, I opened up the gas tank and unscrewed the top off the Weber, found them both to be free of gooey varnish-y rusty horror, rinsed them out, and put them back together. I’ve found that the carburetors and Kugelfischer injection pumps I’ve dealt with are pretty robust, and I don’t rebuild them or send them out to someone else unless there’s compelling evidence that that needs to be done.

So I did what I often do. I went to the computer to see how expensive the part was. I found that an accelerator-pump diaphragm for a Weber 32/36 DGV is only about twelve bucks, so I put one on order. I didn’t know whether or not that was the problem, but in this time when coronavirus is delaying shipments, I wanted to know that the part was on order, and if I didn’t wind up using it, fine.

Next, I remembered that I had another used Weber 32/36 DGV sitting in a box in the basement. A kind-hearted reader had sent it to me a few years back from a car he’d long ago parted out. I thought a moment about the relative merits of swapping it, or parts of it, versus trouble-shooting the Weber that was already in the car, tossed a mental coin, and left the Weber in the box.

So off came the top of Hampton’s Weber. The float bowl was pretty clean, with just a little sediment at the bottom. The pump nozzle was hanging over the barrel—over both barrels, actually, but only the nozzle over the primary barrel is plumbed. With it apart, I verified again that pumping did nothing.

Well, which is easier, pulling the pump diaphragm or checking for an obstruction?

I unscrewed the tube that holds the nozzle down, and blew through the pieces. The hole at the tip of the nozzle is tiny, but it did allow air to pass.

I then worked the linkage lever again to see if fuel came up the hole that the tube and nozzle were screwed into. It remained dry.

I don’t really know Webers or any other carb like the back of my hand (I’m better on the tii Kugelfischer stuff), so I checked online to refresh my memory on how the accelerator pump is fed. It’s not through any of the jets; it simply draws gas through a hole near the bottom of the float bowl. I read that there’s a little ball behind it that acts like a check valve. I was hesitant to stick a piece of wire in there, or to blow through it with compressed air lest I damage something or catch a face-full of fuel. I remembered that in the upstairs medicine cabinet, I had a little squeeze ball (not that I ever actually had an ear-wax issue). Its tip was too big to stick inside the hole in the float bowl, but I managed to get it positioned over it. I gave it a couple of squeezes, and was disappointed that I didn’t see gas rising out of the passageway that feeds the pump nozzle.

Preparing to flush gas into the hole that feeds the accelerator pump.

But then I snapped the linkage open a few times, and sure enough, fuel rose up in response. I reinstalled the pump nozzle over the throat, tested again, and saw a beautiful streaming jet of fuel. I assume that the little check ball inside was stuck, and squirting the fuel in with a little pressure dislodged it.

I put the top of the Weber back on and took the car for a test drive. To no surprise, it started much easier, and when I drove it, it had noticeably more oomph on acceleration than before.

Hopefully that’ll close the book on Hampton’s fuel delivery-related issues.—Rob Siegel

Rob’s new book, Resurrecting Bertha: Buying Back Our Wedding Car After 26 Years In Storage, is available on Amazon here. His other books, including his recent Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, are available here on Amazon. Or you can order personally-inscribed copies of all of his books through Rob’s website: www.robsiegel.com.