I began last week’s piece with the following: “I write this from BMW CCA Oktoberfest in Greenville, South Carolina. I came down in my ’72 2002tii, Kugel, which I drove because I sold it and am delivering it here to the new owners. For years I’ve routinely described Kugel as my most well-sorted vintage car, the one I can hop in and pound out a thousand miles in without any additional prep in advance or drama along the way. Normally, at this point, you as the reader would think ‘Rob, why are you so blatantly taunting the Automotive Powers That Be?’ And next week, I as the writer would go, ‘So, well… funny story.’ But not this time. Kugel knocked off the thousand miles from Newton, Massachusetts, down to Greenville without so much as a hiccup. Which is great, but that makes for a lousy article.”

I also can’t help but add that at the “History Of Roundel Magazine” panel discussion at Oktoberfest, it was said that people don’t read me for “Use 10-mm wrench on Bolt B” step-by-step directions, but to learn how I got into—and hopefully out of—BMW-related trouble.

And with those two preambles, I can say, “S000, well… funny story….”

There were two parts to this trip: driving down in Kugel, and driving back in Louie, my other ’72 tii. The drive down was flawless; it was during the second half, the drive back in Louie, that things went sideways.

And we’ll get to that. But first let’s close out the Kugel story.

I delivered Kugel to its new owners, Jim and Susan Strickland. They’re lovely people. I came to know and trust them through selling them my E28 (“The Lama”) last winter. After we passed papers on Kugel—literally on Kugel, signing the bill of sale and title on the trunk in the parking garage of the Hyatt—Susan said, “We remember that in your first book, in the chapter where you described buying Kugel, you said that after you bought it, the seller pulled out a guitar, and you and he swapped Neil Young songs in his garage, but that while you were towing the car home, you realized that you’d forgotten to play the most obvious song, Long May You Run. We have a guitar in the back of our car. Do you want us to get it so you can play it now?”

I’ll let you in on a little secret: Musicians live to have people ask them if they’ll play, and anyone who tells you different is lying. And this request… how could I possibly turn it down? They got the guitar, and there in the parking garage of the Hyatt Regency Hotel in Greenville, I said the perfect goodbye to Kugel. The video can be seen here.

Long may you run. Maybe the Stricklands have got you now, with those waves singing Caroline… they have waves in Alabama, right?

Jim Strickland and I after I signed Kugel’s title over to him and his wife Susan.

And now, the part you’ve been waiting for, where the Automotive Powers That Be smite the smug Hack Mechanic for his insolence and hubris and leave his smoldering carcass in the breakdown lane, which, months later, will be a greasy spot with a faint odor of brake fluid and CVS dandruff shampoo:

I needed to retrieve Louie, my other ’72 2002tii, which had been in the CCA Foundation museum during their “Icon” exhibit. I’d gone down to South Carolina last January to attend the close of “Icon” and drive Louie home, but my wife called to tell me a blizzard was hitting Boston, and that there was two feet of snow in the driveway—and the garage door was frozen shut. Foundation president Lance White took pity on me and trucked Louie up to his warehouse in Cincinnati; it had been sitting there ever since. As if his generosity hadn’t already been enough, Lance said he’d give me a ride from O’Fest up to Cincinnati when the event was over. So the logistics were in place for me to drive down in Kugel, get up to Cincinnati, pick up Louie, and drive him home after twenty months of sleeping with some pretty pricey pals (that’s Louie, not me).

But there was an issue that nearly derailed the whole thing.

If you read Ran When Parked or saw the near-real-time serialized articles on Roundel Weekly nearly three years ago, you know that during the initial resurrection of Louie in Jake Metz’s pole barn in Louisville, the car was weeping a little oil onto the exhaust, with a drip directly onto the down-pipe. At the time, I diagnosed the source of the leak as a stripped hole for the stud that holds down the lower left corner of the valve cover, making it so that corner couldn’t be tightened, which allowed oil to leak out. I repaired the threads by putting a Time-Sert into the hole. This allowed me to tighten the nut on the stud enough to squelch the leak. I drove the car a thousand miles home that way on its initial trip, and again later that spring, 2,000 miles down to the Vintage and back, without incident.

Oil seeps onto Louie’s exhaust during his resurrection.

Then, a few days before leaving for the trip down to the BMW CCA Foundation twenty months ago, I pulled the valve cover off to adjust the valves, and saw two horrifying things: The first was that the threaded rocker plug had worked itself loose from the end of the intake rocker shaft and was threatening to jump down into the timing chain. I put it back in, and installed a bracket held in place by one of the head bolts to make sure it couldn’t come loose.

The second thing? I found the root cause of the oil leak. The lower left valve cover stud that had been loose wasn’t fully fixed by the Time-Sert because the problem was that the cylindrical boss the stud was threaded into was actually cracked, and tightening the nut on that corner of the valve cover was only making the crack yawn open wider. Further, I could see that someone had tried to fill the crack with blue RTV, so clearly this was known by the car’s original long-term owner.

The partially RTV-filled crack.

In Ran When Parked, I say that whenever I buy a long-dormant car, I always suspect that there’s an underlying reason for its dormancy. In Louie’s case, it’s likely that the PO got an expensive estimate to fix the cracked head, tried to jury-rig it, then parked it.

My driving the car in this condition a thousand miles down to the Foundation for the “Icon” exhibit in February 2018 was risky, but I hated the idea of shipping it. At the time, it didn’t appear to be leaking through the crack, just through the difficult-to-tighten valve cover. I sealed up the valve cover with Permatex (“The Right Stuff” sets quickly, seals incredibly well, but is not trivial to remove) and had no problems on the drive. However, if the crack widened and crept through to the outside of the head, it was likely to dump oil directly on the exhaust, and it’s simply not safe to drive a car that way due to the real risk of fire.

During Louie’s sojourn at Lance White’s, the car was moved several times, and at one point late last spring, one of Lance’s guys, David Morin, contacted me and told me that it was leaking a fair amount of oil. I explained to him about the cracked boss at the back of the head, but to my surprise, he said it appeared to be leaking from the front. Since I’d had the upper timing cover off as part of repairing the business with the plug in the end of the rocker shaft, anything was possible.

Above all, I hoped that the quantification of “leaking a fair amount of oil” could be explained by the difference between maintenance to the high standard of Lance’s cars as opposed to my more lax bottom-feeder metric, and that when I picked up the car I’d find that it wasn’t leaking any worse than when I’d driven it down twenty months ago, but I had no way to know. To be prepared, I came down with gaskets for the valve cover and the upper timing cover, along with a number of different sealants. I also had some J-B Weld (two-part epoxy), both the standard stuff and the fast-setting KwikWeld, but that’s just part of my emergency kit; I certainly wasn’t going there planning to deploy the nuclear option.

After a delightful (and very fast) drive from Greenville to Cincinnati with Lance in his E90 M3, I stayed overnight with my friend Scott Aaron and his wife, Stacy. In the morning, Scott dropped me off at Lance’s shop. There I met up with David Morin and Lance’s chief mechanic, Safet Hatic, whose wisdom and experience I’ve benefited from before. We drove to an outbuilding about a mile away, where Louie was stored. I picked up the car and drove it over to the main shop. Dave cleaned old caked oil and grease off the front of the valve cover. We ran the engine in the shop, but didn’t see any leakage, so I took the car for a longer drive.

Safet brings Louie down from his penthouse.

When I got back to the shop and opened the hood, the front of the engine was still clean, but there was substantial oil smoke rising from below the back of the head. Damn! I swiped a paper towel on the lower rear corner of the valve cover, but it came up clean, so the source didn’t appear to be the valve-cover leak I’d last seen. We put the car up on the lift, and could see oil coming from the general vicinity of the lower left corner and dripping directly onto the downpipe, but I couldn’t figure out the exact source.

I began to get very concerned. It was clearly a fire hazard; there was no way I’d drive it much farther that way , much less up to Boston, unless it could be fixed.

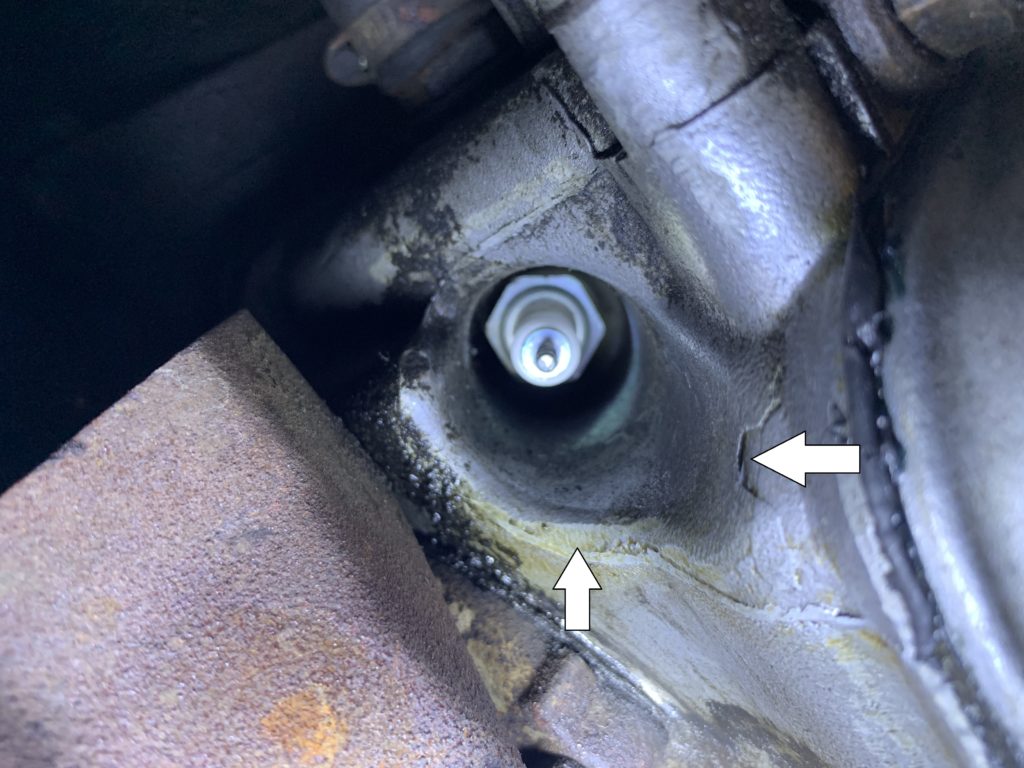

Dave took a borescope inspection camera, poked around in places you couldn’t easily position your eyeballs, and found the source. It verified my fear: The crack through the valve-cover-stud boss had progressed through to the outside of the head, and oil was running down from there, around the #4 plug hole, and dripping right onto the exhaust.

Inspection camera photo by Dave Morin: Upper horizontal arrow shows the crack. Lower vertical arrow shows the path the dripping oil took around the plug hole.

I was crestfallen: Clearly I would not be driving the car back to Boston. I took out my phone, began researching one-way flights home, and found the contact information of a shipper I’ve used recently. I hated that Louie’s adventure would end so ignominiously, but there seemed to be little alternative.

Then I took a step back and gave myself some breathing room.

I confirmed with Scott Aaron that I could stay overnight at his house again if I needed to. I gave myself until the end of the day to exhaust all options. And just then my friend Paul Wegweiser called me; I’d planned to retrace Louie’s and my original drive and stay that night at Paul’s in Harmony, Pennsylvania, and he was asking about my ETA. I explained what was going on, and said, half-jokingly, that both my Hack Mechanic image and my self-image were going to take a big hit if I bailed, shipped the car back, and flew home instead of manning up and coming up with some gonzo hack. Paul was great. I forget his exact words, but the gist of it was “Don’t you dare let that factor into your decision. Do what’s right, do what’s safe.” I appreciated the reasoned feedback.

But I’ll admit that expectations did play a role. It was funny that Paul called when he did, because I was recalling being at the Vintage in 2012 when Paul and Ben Thongsai changed the blown head gasket in Paul’s tii in the parking lot of the hotel in under two hours, pulling the head off before they even had a replacement head gasket in their hands. This singular event set the bar in the vintage-BMW community not only for what’s possible, but for what those with merit attached to their names can be expected to do.

In fact, I had a full head gasket set in Louie’s trunk, just in case age caught up with it and I needed to pull that rabbit out of the hat. However, even though there was probably no better place on the planet to be with a cracked 2002 head than in Lance’s shop and with Scott Aaron’s house a few hundred yards away, this wasn’t simply a case of yanking the head off and dropping the same head back on. It was pretty clear that the head needed to be replaced.

Safet offered that they had a bunch of 2002 heads in the warehouse. We looked through them, but a ’72 tii like Louie is unusual; it has a 121ti head with the large 46-mm intake valves (carbureted pre-’73 2002s have 121 heads with 44-mm intake valves), and there was nothing like that on the shelves. Even the valve size notwithstanding, most of the heads that were there were bare, bereft of valve-train components; there certainly wasn’t anything that could simply be dropped on. And even if there was an appropriate bare 121 big-valve head, the odds of doing the necessary valve job and reassembly that day were essentially zero.

I pulled off the valve cover, prying off the death grip of “The Right Stuff” adhesive I’d applied twentymonths ago. Hmm: The crack didn’t really look any more nasty from the inside than I remembered.

The crack, revisited.

Figuring that I’d forestall the whole “Just J-B Weld it” thing that people say when it’s not their problem, I mentioned, almost in passing, to Dave and Safet that I had some J-B Weld in the trunk. To my surprise, Dave nodded and said, “That might work. Flush out the crack from both sides with brake cleaner, then heat it up with a torch to draw out and burn off any remaining oil.” I forget which one of them advised to use the J-B Weld both inside and outside, and to not only pack it into the crack but slather it over the whole general area. They both seemed to think it stood a fair chance of working. Safet pragmatically added that it didn’t need to completely seal the leak, it just needed to not leak oil directly onto the exhaust.

And so I had at it. I liberally sprayed brake cleaner inside, outside, and down the threaded hole. I borrowed a torch from the shop and used it to dry out the area and burn off the oil, as well as bake out the old RTV that was in there. I did this twice for good measure. I mixed up the J-B KwikWeld, and applied it with a piece of a paint stirrer Safet found for me.

Boil, bubble, toil and trouble.

J-B on the inner crack surface.

The part on the outside of the head had to be done blind, as due to the overhang of the head, there was no way to see it directly. (And, oh, have you even gotten J-B Weld on the screen of your phone when trying to operate it in selfie mode? No? Well, then, you can’t second-guess the part about not being able to see this directly, can you?) After laying the J-B Weld on, I reached under with my Latex-gloved hands, worked it into the crack, and smeared it around.

The blindly-slathered J-B Weld adorns the outside corner of the head.

As I was doing this, Safet looked at the cracked boss closely, and recommended that I squirt some sealant into the threaded stud hole to try to seal the crack from the inside. He rooted around and found some pipe dope he thought would fill the bill. I of course took his advice and packed the hole, gently threaded the stud into it, and wiped off the excess.

As I waited for the J-B to set, I removed the old valve-cover gasket and cleaned the adhesive off both surfaces with a razor blade. Since I knew that I’d be pulling the thing back apart as soon as I got the car home—if I got the car home—I thought I’d use a less tenacious adhesive, so I coated the bottom of the gasket with Aviation Form-A-Gasket. (Satch has been known to build entire engines using this stuff, which may tell you how old he is.) I waited about an hour for the KwikWeld to cure, running a heat gun that Safet had loaned me over it lightly. When it felt hard to the touch, I buttoned up the valve cover, lightly tightening the nut on the lower left stud. I started the engine and held my breath.

Oil dripped onto the exhaust. Damn. (Actually, I didn’t say “damn.”)

But when I swiped the area with a paper towel, it was immediately obvious that the oil was coming not from the crack, but from the valve-cover gasket; I’d made a serious error in judgment in using a light sealant. I pulled everything apart, cleaned the metal surfaces and the gasket as best as I could (it was the only one I had) with brake cleaner, and began to apply “The Right Stuff,” which comes in a pressurized can with a nozzle that you bend to let it out.

Unfortunately, I found that since I’d last used it, the propellant had leaked out.

I called the nearest Advanced Auto Parts and found that they had the sealant in stock. Safet gave me a ride. I thoroughly coated both sides of the valve-cover gasket, taking care to lay it on thick at the lower left corner, and reinstalled the valve cover. I tested it again, and this time it appeared to hold; I saw no indication of leakage.

I took Louie for a drive of several miles, came back to the shop, lifted the hood, and saw no oil smoke. The paper-towel swipe came up dry. Dave hooked up the borescope again, poked around near the weld on the outside, and saw nothing.

Well, all rightie, then.

It was 4:00 p.m. I punched Paul’s address in Harmony into Waze. It reported about 300 miles, about five hours. From there to my home in Newton was about twice that distance. If I wanted to be home tomorrow, I needed to leave for Harmony now.

I vociferously thanked Safet and Dave, threw the bags and boxes I’d transported on the back seat of Lance’s E30 M3 into Louie, took the fire extinguisher from the trunk and put it on the passenger floor, and hit the road. When I stopped about ten minutes later to fuel up before hitting the highway, I dutifully opened the hood and saw no oil smoke.

After that, I just went for it; I didn’t directly check for oil leaks again. I’m not saying that it was right, I’m just saying that’s what I did. (Yes, I’ve used that line before. It’s a good line. But stealing your own lines is bad. I’m not saying it’s right, I’m just saying it’s what I did.)

As one often does when driving any hobbled car, initially I hugged the right lane, but once I was reassured that the car appeared to be free of fumes indicating that oil was dripping on the exhaust, the car and I settled into a rhythm.

Taking a step back for a minute, remember that I’d driven down in Kugel, my very-well-sorted Chamonix ’72 tii, a fully-specced car stem to stern with a five-speed, a redone suspension with Bilstein HDs and big sway bars, rebuilt steering, and 320i Recaros. I’d sold it and was now driving home in Louie, also a ’72 tii, but bone-stock, with its original four-speed, uncomfortable 47-year-old horsehair-padded seat, and unsorted original suspension and steering that made it feel more than a little bit floaty and boaty—plus 13″ tires that were flat-spotted from having sat for twenty months. Hardly the deftly-wielded carving knife that Kugel felt like, and now with a cracked head. I’ll admit that I did think, “WHAT THE HELL DID I JUST DO?”

But the more I drove it, the more I was reminded of why I’d made this choice: The tired suspension notwithstanding, Louie feels exactly the way a bone-stock ’72 tii is supposed to feel, and I love that. Both cars had wound up where they were supposed to be.

I made it to Paul’s house in Harmony, swung Louie around to park in front, rolled up the driver’s-side window, and the window regulator broke. I could not have cared less. I went inside and had a lovely evening with Paul and Wendy (to whom I privately refer using the unusual pronoun Why haven’t you married that woman?).

The next day I woke to drenching rain that was predicted to continue to Boston. I was concerned about the broken window regulator, but the window stayed up without any mechanical aids.

Pretty picture. Not-so-pretty morning drive.

I nutted up and pounded out the ten hours and 600+ miles. The first three hours were in stiff rain, but I consoled myself that if the head repair failed and began dumping oil on the exhaust, at least the rain would prevent the car from catching fire. Fortunately, by lunchtime the skies had largely cleared. I pulled into the driveway of my house in Newton just before dark.

So, yeah, that Hack Mechanic guy fixed a cracked head with J-B Weld and drove 850 miles home. In your face, Automotive Powers That Be! But before you go all fanboy on my tuchus, know that I never would’ve been able to do this without the advice and expertise from Safet Hatic and Dave Morin, and Lance White’s generosity. The tip to use the torch was likely key.

Home, home again…

I thought that I’d pull Louie into the garage, set him in the spot of honor on the lift, and immediately begin yanking his damaged head off, but I don’t yet have a replacement. And since the repair appears to be holding, I think I’ll wring every hour of autumn driving out of him first. Maybe I’ll give him a present and change those wallowy original shocks and struts for the used set of Bilstein HDs I’ve been saving for him in the back of the garage. He totally deserves that.

So Kugel’s gone, but Louie’s back, with his mojo and legend not only intact, but enhanced. Long may you run.

Now, regarding Hampton, the 48,000-mile 2002 I bought last month: Well, funny story….—Rob Siegel

Rob’s new book, Resurrecting Bertha: Buying Back Our Wedding Car After 26 Years In Storage, was just released and is available on Amazon here. His other books, including his recent Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, are available here on Amazon. Or you can order personally-inscribed copies of all of his books through Rob’s website: www.robsiegel.com.