Ahead of introduction of the X5 xDrive45e and X3 xDrive30e, which are slated for production to commence in December, BMW Plant Spartanburg in South Carolina has more than doubled its battery production capacity. These two electrified SAVs are based on two of the most popular BMW models available right now, and demand for the plug-in hybrid versions is expected to be strong.

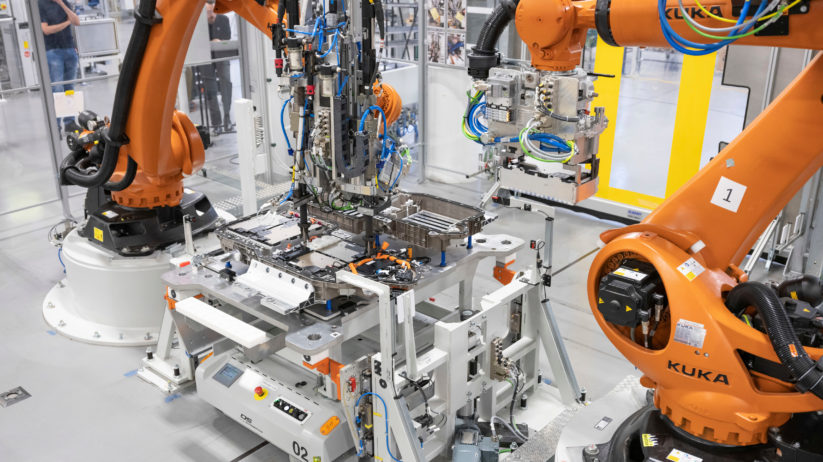

To keep up with the market, BMW invested approximately $10,000,000 into its largest manufacturing facility, adding 86,000 square-feet of battery production floor space, while another $10,000,000 was spent to support production of the new PHEV variations of the X3 and X5, the former of which is the best-selling BMW model right now. In addition to space and equipment, 120 plant workers have been specially trained to work the new battery line, while another 225 have been prepared for producing the vehicles the cells will power.

The G05 X5 xDrive45e is a followup to the F15 X5 xDrive40e, the first-generation hybrid version of the model. From 2015 until 2018, this model was produced at Spartanburg, and during this time, more then 45,000 battery units were assembled by plant staff. With the move toward electrified drivetrains only gaining momentum, BMW is now prepared to manufacture more than double that amount for the X5 xDrive45e and X3 xDrive30e.

The X3 xDrive30e will not be the only X3 version available with an electrified drivetrain though. In addition to the hybrid 30e, BMW will also soon be selling the exclusively Chinese-built and electrically-motivated iX3 globally. Production of the iX3 is scheduled to begin next year in Shenyang, China, and the fifth-generation eDrive unit solely responsible for motivation is expected to provide approximately 250 miles worth of range. Contrary to previous models from the i brand, it also uses a more conventional design, with an appearance that almost mirrors the conventional X3.

BMW brass says the investment in battery production makes the automaker a pioneer in electromobility in the U.S., following the principle of local value creation. Production at BMW Plant Spartanburg commenced more than 25 years ago, and in the quarter-century since, over 4,600,000 BMW vehicles have rolled from its doors. The latest manufacturing schedule includes the X3, X4, X5, X6, X7, and all of their individual variants. In 2018, BMW Plant Spartanburg was the largest automotive exporter by value in the U.S. for the fifth year running.—Alex Tock

[Photos courtesy BMW AG.]