In last week’s piece, The End Game, I went full left-brain on you, detailing Bertha’s four separate driveline noise-and-vibration issues:

- Bad Getrag 245 5-speed transmission that munches fourth gear, whines when you get on the gas, and rumbles when you get off it.

- Out-of-alignment giubo with short projected life.

- Out-of-alignment driveshaft causing a light vibration.

- Differential—with seized fill plug—that rumbles lightly at low speed with the transmission in neutral.

I said that these issues didn’t sound like much individually, but collectively they were causing me to eschew a road trip until I addressed them. But after I sent in the article, I re-read it, and one word came to my mind: wimp.

Although I hadn’t mentioned it in last week’s article, the BMW CCA Vermont Chapter event, OktoberFAST, was happening up in Burlington that very weekend. I’d already talked myself into (and then out of) going, both because of Bertha’s driveline issues and because I had a gig the night before; that’d mean having to drive up Saturday morning and home Saturday night. Round-trip, it looked like close to 500 miles—a stretch, but certainly not impossible if I wasn’t, you know, a wimp.

I reconsidered.

I took Bertha for a quick spin around the block. Nope, I thought; this doesn’t feel right. This feels like something will go BANGwobblewobblewobble eighty miles south of Burlington. As I wrote in my first book, I often recall the Star Trek parable of the brave Klingon warrior who stays outside when a ferocious sandstorm is approaching. He says he is not afraid. He dies. Moral: The wind does not respect a fool.

I try not to be a fool. That sometimes means being a wimp. But an informed wimp. Totally different.

However, as a writer who fixes cars, I sometimes become fixated on the idea that I can change the ending to a story, make it right by applying the correct combination of sweat, parts, ingenuity, and risk, and change wimp to cool dude. So even though my left brain said “Don’t do it,” I badly wanted to begin this next column by saying “Well, I ignored all my own advice, and Bertha and I burned up I-93 to I-89 to Burlington, went to OktoberFAST, Bertha was awesome, and everyone loved both of us because we are so cool.”

That didn’t happen. But something pretty amazing did happen.

At the end of last week’s article, I said, “I’ll probably spend the eighty bucks, try the Swepco [gear oil], swap the differential, make another stab at aligning the giubo, and see where that puts me before sailing too far from shore.” There’s nothing like one’s own punch list to get one moving, so I winced, sighed, and ordered the $80-a-gallon Swepco 80W90 gear oil, thinking that for that price, it’d better goddamn have baby seal tears in it. And then I prepared to do the next thing on the list: swap the diff.

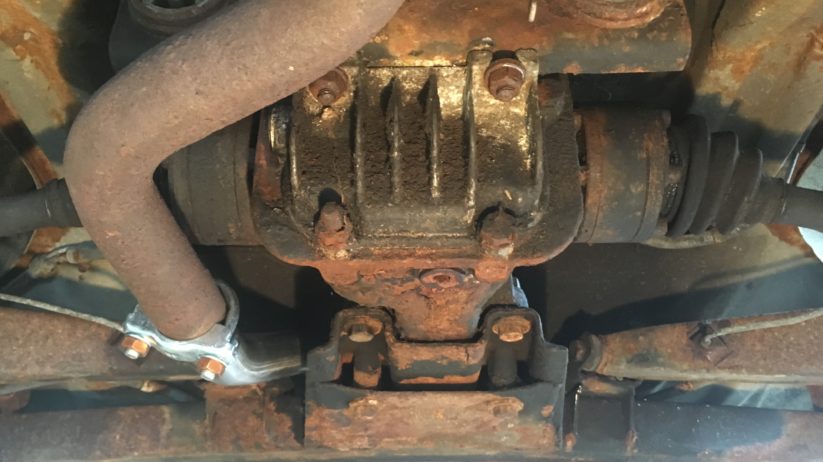

First, I performed some household archaeology and unearthed the spare differential. I believe it originally came from the same 2002ti that Bertha’s front struts and brakes came from. The spare diff had been sitting under my mother’s front porch for over 30 years before I finally moved it and some other parts over to my house in Newton a few years back. Then it sat under my porch. (I like to think of this as “seasoning.”) I spun it to verify that it was munch and rumble-free, cleaned it off, verified that it was stamped “40 11,” giving it a 3.64 ratio, then made sure that neither the fill plug nor the drain plug was seized.

Next, I put Bertha on the lift, and did some forensics to be certain that the diff really was noisy. While driving the car, it certainly sounded like there was one set of noises coming from the transmission—the whine and the rumble when on and off the gas—and a distinct light rumble coming from the rear of the car, audible when coasting at low speed in neutral. Sure enough, with the car in the air, the engine loafing at idle, and the transmission in second gear, there was a clearly audible rumble from the back of the car (you may listen to it here). Of course, rumbles are notorious for telegraphing their way through a car, and even when underneath it, it’s not easy to isolate a rumble to the differential as opposed to the half-axles or the rear wheel bearings.

If a differential is low on fluid, it will almost certainly be noisy. But I didn’t know that this diff was low on fluid; as I said last week, the diff’s fill plug was seized so badly that even heating it red-hot with a torch, applying wax to the circumference, and tapping the Allen key in with a hammer, the Allen hole stripped, so there wasn’t any way to check the fluid level or fill it with the diff in the car. Of course, I could undo the drain plug and see how much came out, but with no way to refill it, I didn’t want to touch it unless I was committed to removing the diff.

The best way to isolate rumbles is with a mechanic’s stethoscope, but the entropy in my garage swallowed mine, so I used a hose held to my ear, with the other end pointed at various components. The sound seemed to be coming from the right side of the rear end. I didn’t feel any play in the right half-axle, but to be certain it wasn’t the cause, I disconnected the right half-axle from the differential’s flange and ran the car in gear. The noise lessened substantially. I swapped the half-axle with a spare. The noise came right back. I supposed it could’ve been the right wheel bearing. I removed the half-axle entirely and spun the right wheel. Nothing. Hmm.

I theorized that the differential was behaving differently when there was a torsional load on it and when there wasn’t. It wasn’t a 100% clear-cut “Yes, this differential is bad,” but swapping a diff isn’t that big a deal, especially if you have a lift, a floor jack, a compressor, and an impact wrench, so rather than wondering about it, I just went ahead and replaced it.

I discovered, though, that I’d positioned Bertha inconveniently on the mid-rise lift. There are certain orientations where the differential is over part of the base of the lift, making it so that you can’t roll a floor jack directly beneath the diff, and this was one of them. I had to skooch the front of the floor jack up onto the angled legs of the lift. It was a little hairy, but workable.

I remembered swapping a differential as easy. As one gets older, one is thankful for mechanical aids.

Out came the old diff. Out of curiosity, I drained it. Only about a cup of fluid came out, much less than the 1.5-quart fill capacity. That explained a lot. I suppose I could’ve filled it through the drain plug and re-installed it, but I already had the other one ready to go.

I filled the replacement differential and balanced it on the jack. Installing it required a bit of care, as it was difficult to position the floor jack accurately due to the interference from the base of the lift. I marveled that I used to simply lie on a creeper, put a differential on my chest, roll beneath a car, bench-press the thing into place, and hold it there with one elbow-locked arm while threading bolts in place with my other hand. Even using the lift, the whole thing was a lot harder than I remembered. I wondered what portion of that was my fading upper body strength, and what portion was my fading memory.

But in it went. I snugged down the bolts, fired up the engine, put the car in second gear, and smiled as the low-speed rumbling noise was gone. Bliss. (See the video here.)

But that’s not the amazing part.

As I said at the beginning, I’d diagnosed four separate driveline issues with Bertha; the low-speed rumbling in neutral from the diff was only one of them. The car still had a transmission that whined badly when you got on the gas, and rumbled badly when you got off it. And munched fourth gear. My decision to blow eighty bucks on Swepco was a Hail Mary pass at trying to quiet the thing down.

The Swepco wasn’t due to arrive until the end of the week. Bertha was already on the lift. The E9 was behind it. Rain was forecast for the next few days.

The lazy part of me, and the part that likes to keep the E9 out of the rain, both thought that I should just leave Bertha on the lift so that when the Swepco arrived, I could drain the transmission, pump the Swepco in, and see what the result was. But the rational part of me thought that if I did that, I wouldn’t know what part of the problem the diff swap solved and what part was cured by the baby-seal tears in the Swepco , but it was really little more than an academic argument. I was confident that I could distinguish transmission noises that were coming from right next to me from differential noises that were coming from the rear of the car.

Laziness and E9-related moisture fear won. I decided to leave the car on the lift and wait for the Swepco.

But the next day, the rain unexpectedly cleared. I moved the E9 out of the way, took Bertha down off the lift, and drove her. To my stunned surprise and delight, with the differential swapped, the whining and rumbling when on and off the gas were completely gone. I was dead wrong about their origin; they were never coming from the transmission at all, they were coming from the rear end.

There’s still a light vibration that could be giubo or driveshaft-related, and the five-speed still munches going into fourth gear. You can ease it in on upshift, but when rowing from fifth to fourth, as one needs to do with a 2002 five-speed on the highway, if you don’t double-clutch and match revs perfectly, it offers up a loud, nasty, metallic crunch.

But at the gut level, Bertha feels ready to go somewhere. And I feel ready to let her. Anyone wanna buy a gallon of Swepco?—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.