As I write this on the Friday evening before Oktoberfest, I stand on the precipice of either achieving jaw-dropping success in getting Bertha running well enough to drive to Pittsburgh on Tuesday and ensuring the continuation of my Hack Mechanic legend, or tucking my tail between my legs and saying that it was never an actual goal.

Me, I’d bet on the latter. (I’m warming up the slice of humble pie in the microwave as we speak). Right now, it’s all about Bertha’s head.

Decapitation is so messy.

As soon as I got Bertha home several weeks ago, I yanked her head and took it to the machine shop (Century Automotive Machine in Waltham). A few days later, Hal, the owner, told me that the head had one bad intake and one bad exhaust valve, so I needed to order those parts. The exhaust valves in 2002s are all the same size (38 mm), but two different-sized intake valves were used; all tii’s and all post-mid-1972 02s with the E12 head had the larger 46-mm intake valves, but early non-tii’s with the 121 or 121ti head had the smaller 44-mm valves. Since I knew that the engine in Bertha was from a ’72 tii with a 121 head (and I knew this because I had rebuilt and installed the motor), I was sure that the head had 46-mm intake valves.

I was so certain of this that I didn’t bother to measure—or ask Hal to.

Except that I was wrong. I ordered the valves, including a 46-mm intake valve, and was stunned when Hal called me a few days later and told me that the intake valve I’d ordered was too big. (Actually, what he said was, “Whoever you ordered the valves from screwed up.” I said, “No, the mistake was all mine.”)

“So the correct size,” I asked, “must be 44 mm, right?” He measured and confirmed. I immediately got the correct one on order.

I had to think long and hard about the discrepancy. I checked the VIN on Bertha’s block, and it did indeed start with 276, verifying that the block came from a tii (an Inka ’72 that I used as a winter beater 34 years ago). While looking at Bertha’s block, I could also see where I had blocked off the oil port that originally plumbed the Kugelfischer injection pump. But how could I have been wrong about the head?

Then I remembered that when I stripped Bertha’s head to take it to the machine shop, I noticed that it had a block-off plate for the hole for the fuel-pump rod. This surprised me, since a tii has an electric fuel pump and thus has a unique head that doesn’t have the hole for the pump rod; if Bertha’s head was from a tii, it shouldn’t have had a block-off plate. At the time, I shrugged and thought that perhaps a previous owner of the Inka tii had cracked the head at some point and a non-tii head was used to replace it.

The more I thought about it, though, the more I realized that it was more likely that Bertha’s head came not from the Inka tii but from the other major source of her DNA.

In the mid-’80s, I bought and parted out a rusty 2002ti with a bad engine. (If you don’t know, the never-commercially-imported 2002ti was the predecessor of the tii, essentially a tii but with dual sidedraft carbs instead of injection, and using the same improved braking system). This was where Bertha’s Weber 40DCOE carbs, struts, big calipers, and brake booster came from. With all the parts that came from the ti, Bertha was sort of a big-bumpered ti tribute car. In fact, decades ago, I took the “2002ti” badge off the parts car and slapped it on Bertha. The first two digits fell off some time during Ronald Reagan’s second term. To this day, on Bertha’s rump, there is a fragment of a badge that says “02ti.”

Bertha still proudly shows her genetic makeup by wearing her “02ti” badge.

After the correct 44-mm intake valve arrived at the machine shop, Hal called me and reported that there was another problem. “You have one bad valve guide,” he said. “I’m sorry that I didn’t catch this when I told you to order valves.” It was a shame, as it was sure to impart another delay in the project.

But hey, this is the advantage of living less than a hundred miles from Roundel advertiser Bavarian Autosport: When they have an item in stock, and I place an order in the morning, they usually get it to me the next afternoon. I smiled when I found that they had valve guides in stock. I filled in the address of the machine shop and submitted the order, secure in the knowledge that the guide would be at the machine shop soon.

This is the Sanden 508 compressor I’d installed in Bertha over 30 years ago, with a new O-ring head on the back.

While waiting for the head, I continued to clock through Bertha’s punch list. In addition to the necessary braking, exhaust, and fuel-delivery issues I wrote about last week, I made great strides on reviving the air-conditioning. I removed and flushed the evaporator assembly, replaced the expansion valve, installed a new parallel-flow condenser and fan, swapped the head on the back of the Sanden 508 compressor so that I could use O-ring fittings instead of flare fittings, and mounted the bracket, compressor, and belt on the engine. On Facebook, I joked that while the odds of my driving Bertha to O’Fest were still slim to none, if I drove her in the 90-plus-degree temperatures we were experiencing, I was not going to be an R75/2 guy (75 mph, two windows down).

In truth, even though I was downplaying expectations publicly, I thought that if I got the head back from the machine shop two weeks before my drop-dead departure day for O’Fest (Tuesday, July 12), it wasn’t completely outside the bounds of the possible that I could get the head on, get the ancillary engine components reattached, and drive the 26-year-dead car enough to find out whether a 1,200-mile round trip to Pittsburgh was smart, practical, possible, unwise, folly, madness, or suicide.

Unfortunately, a few days after ordering the guide, Hal called me and said that the guide that Bavarian had sent wouldn’t work without a fair amount of extra machining. He said that my car had standard-sized old-style valve guides, and that what I’d ordered from Bavarian was a new-style guide in the first oversize. One trivial issue was that the set of valve seals I’d given Hal were for the old-style guides; in order to use the new-style guide, I’d need to procure a new-style seal. But the larger issue, Hal said, was that he’d need to machine the head to receive the oversized guide, and this might cause concentricity issues with the valve seat, which would add to the cost of the job.

Old-style (left) versus new-style (right) 2002 valve guides.

Now, in the 2002 world, the new-style guides exist because the old-style guides and seals have a reputation, as the guides and seals wear, for allowing oil to get past the valve stems and into the engine when you let off the gas, creating a do-it-yourself James Bond-style smoke screen. The standard advice is that when you rebuild a 2002 engine, you should change to the new-style guides and seals. That’s fine advice, but I was trying to not rebuild Bertha’s engine; I was trying to get the car back up and running as cost-effectively as possible.

Back online I went. I first posted the issue on Facebook, saying that I needed either a standard-size old-style guide, or a standard-size new-style guide and matching seal. Then I searched e-commerce sites for a click-and-buy old-style guide. The only sources I found were an eBay auction in California, and RockAuto. I clicked on the latter.

RockAuto is generally very prompt with shipping, but you don’t know where they’re shipping an item from until they send you a tracking number. My heart sank when I saw that the guides were shipped via Fedex Ground from California, and that delivery wasn’t scheduled until end of day on Friday, July 6.

I called Hal at the machine shop, explained the delivery time and the deadline I was trying to make, and asked what the odds were of getting the head in time to install it over the weekend. “If the guide isn’t there at 8:00 a.m. Friday morning, there’s very little realistic chance,” he said. “And I know Fedex’s delivery schedule. It’ll likely show up mid-afternoon.”

Your Hack Mechanic was sad that events were not going his way.

Sometimes you may not like an answer, but with the answer comes clarity. The world cleaves neatly into the possible and the not possible. I found myself far more disappointed than I expected to be that the possibility of driving Bertha to O’Fest was taken away from me—if I failed, I wanted it to be my failure—but it meant that I could relax. And besides, I’d just installed a new Walloth Nesch “extra cooling” radiator in Kugel, my ’72 2002tii, replaced a leaky a/c condenser, charged it up with good-old-fashioned R12, driven the car in 93-degree heat, and experienced a cool-running engine and 35-degree vent temperatures. Driving Kugel to O’Fest would not be hardship.

I posted this idea on Facebook, preceded by the overly-dramatic heading, “Time of death of the possibility of driving Bertha to O’Fest: 4:45 p.m.”

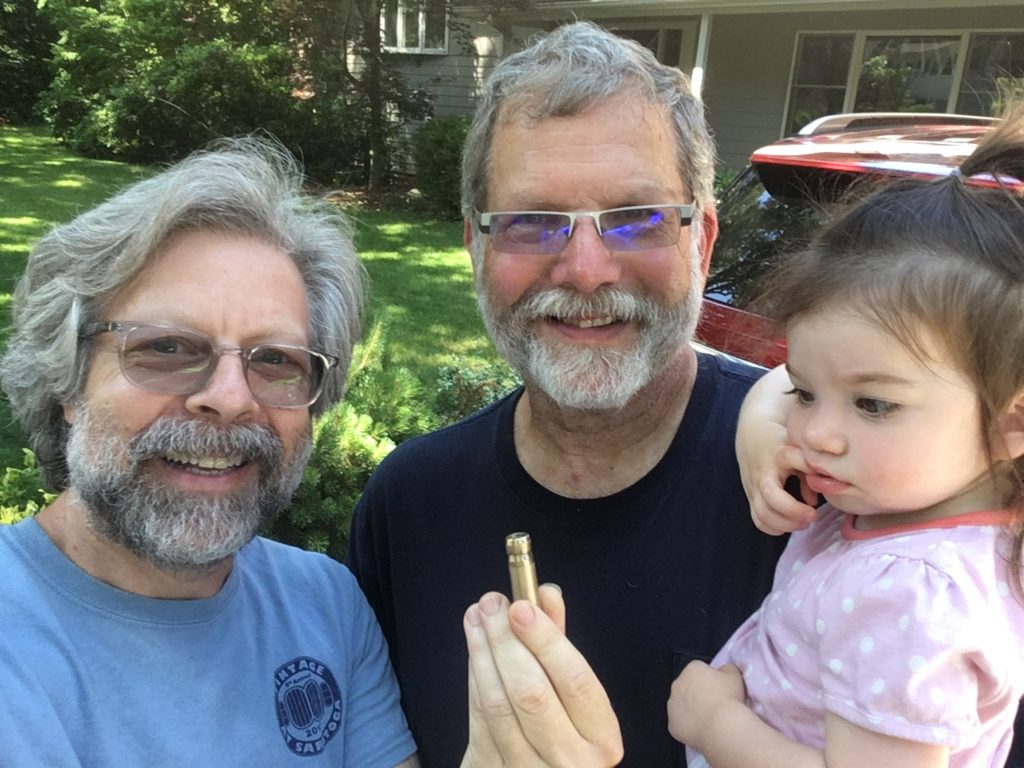

And then something most unexpected happened. On the morning of July 4, CCA member Jonathan Selig sent me a message saying, “Just saw your Facebook note regarding valve guides for Bertha. Let me know if these are the ones you’re looking for.” He attached a photo clearly showing four old-style guides removed from a box labeled “std.”

Wow.

Except, well, shipping. It was the 4th of July. Even with one-day shipping, if he got them in the mail the next day (Thursday), they’d arrive Friday, still almost certainly too late. But when I clicked on Jonathan’s Facebook profile, I was overjoyed to see that he lived in Acton, Massachusetts, about twenty miles from my house. I then remembered that I’d been to his house at least a decade ago, looking at the Ceylon 2002tii project car that he’d been thinking about selling. “Could I come over and grab one of these right now?” I asked.

In a flash, I was at Jonathan’s house. The Ceylon tii was still in the garage (“And thank you for not buying it,” he joked). He opened a cabinet stocked with engine parts for whenever he gets around to the tii, and handed me the correct valve guide. I couldn’t believe my good fortune.

Jonathan Selig and his granddaughter present me with the valve guide from heaven.

Early the morning of Thursday, July 5, I drove to the machine shop and taped the valve guide to the door with a note for Hal. I then called the shop, expecting to leave a message, but was surprised when Hal answered the phone. He said that with the guide in hand, if nothing went wrong, he could probably have the head for me Friday morning.

So, as I write this on Friday evening, that is exactly what happened about ten hours ago. I have Bertha’s head back. I tried to tip Hal twenty bucks, but he would have none of it. (He did, though, let me give him an air-conditioning book.)

Few things are as satisfying as a fresh-from-the-machine-shop head.

Since picking up the head this morning, I’ve been frantically trying to reassemble it. I knocked in the exhaust-side rocker shaft, threading the rocker arms, springs, spacers, and washers onto it, but when I tried fitting the snap-around clips, I found that the rocker for the #4 exhaust valve was bound up, presumably due to galling on the running surface. I had to knock the shaft back out and substitute another rocker arm, which, fortunately, I had as a leftover from when I rebuilt Kugel’s head (score another one for never throwing anything away). This is what happens when you rush; I’d normally have test-fit all of the rockers on the shafts to check for clearance problems.

If there are no other rocker-related issues, I expect to get the head reassembled tonight, and to begin re-fitting it to the block tomorrow. It’s going to be close; I still expect to be be driving to O’Fest in Kugel.

But hey, the fact that Jonathan Selig produced the correct valve guide out of thin air has got to mean something. At least if I fail, it’ll be my own failure.—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.