I’ve embarked on a project on my 1969 Lotus Elan +2 that some of you might find interesting. Not only am I retrofitting air conditioning into it, but I’m using an electrically-driven compressor. For the last few weeks, the project has consumed me, driving out all BMW-related wrenching. So, like it or not, that’s what you’re going to hear about.

The genesis of this project was a comment from a Facebook friend who electric-converted his E30 made to me a few years ago. He said that, in addition to scavenging electric motors and battery packs from crashed Teslas, people use the electric compressor. I never thought about it, but of course these cars have electric compressors, and if someone is doing an electric conversion on a vehicle and they want air conditioning in it, they kind of have to use the electric compressor, as there’s no longer a crankshaft pulley to drive a belt-driven compressor off. But the fellow said that another advantage is that because the compressor isn’t driven off a belt, you can mount it anywhere. Intrigued, I looked into it, found that the Tesla compressor is powered by the car’s high-voltage electrical system and thus, like any other EV or hybrid compressor, isn’t applicable for retrofit into a 12-volt car. “Well,” I thought, “I’ll never do that,” and filed it in my head with other useless automotive trivia.

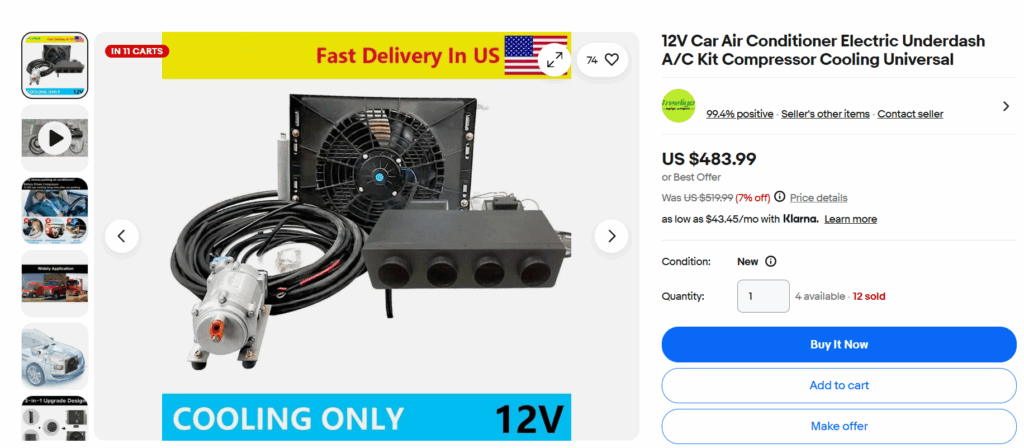

But because I often write about automotive air conditioning, the question of “can you use an electric compressor” kept coming up. I began to see 12-volt electric compressors on eBay for as low as $220, whole “universal” systems using them for less than $500, and videos on YouTube of folks installing them into vans and trucks and claiming that they were the best thing since guilt-free sex. I looked into them a bit further, and became highly skeptical. The application of Watt’s Law (P=I*V, or power equals current times voltage) means that it’s much easier for a high-voltage electric vehicle to generate a given amount of power at a low level of current. But for a conventional 12-volt electrical system, the amperage required to generate the same power skyrockets. Sure enough, the 12-volt electric compressors on eBay draw about 60 to 80 amps of current. That’s probably double the entire electrical load on a vintage car except the starter motor.

One of many cheap a/c systems powered by an electric compressor being hawked on eBay.

In addition to that, electric compressors have a triple inefficiency built into them. A conventional belt-driven compressor is efficient because it’s directly coupled to the rotation of the engine to the rotation. In contrast, with an electric compressor, the spinning engine turns an alternator, which generates current that’s used to spin a three-phase electric motor, so an inverter is required to turn the direct current (DC) into alternating current (AC). That, in turn, spins the electric motor that’s paired with a compressor. The laws of thermodynamics tell you that there’s no way for it to be as efficient as a belt-driven compressor. Lastly, a back-of-the-envelope calculation of the wattage and projected BTUs of these small electric compressors made me doubt that they’d ever be able to actually cool off a heat-soaked car.

And that was that.

Until summer ramped up and I found out how uncomfortable my Elan +2 was inside. Like many British cars of this era, the amount of engine heat that finds its way into the cabin makes it a hot drive. And unlike a 2002 or an E9 or most vintage American cars, it doesn’t have triangular vent windows you can open and use to force outside air in. As you probably know, I’m a big proponent of installing or resurrecting a/c into vintage cars, as it extends your driving season and thus your enjoyment of the car. I’ve done it multiple 2002s, my ’73 3.0CSi, and my ’79 Euro 635CSi, and the idea that anyone would ever regret doing it is laughable. So I began to look seriously at an a/c retrofit in the Elan +2.

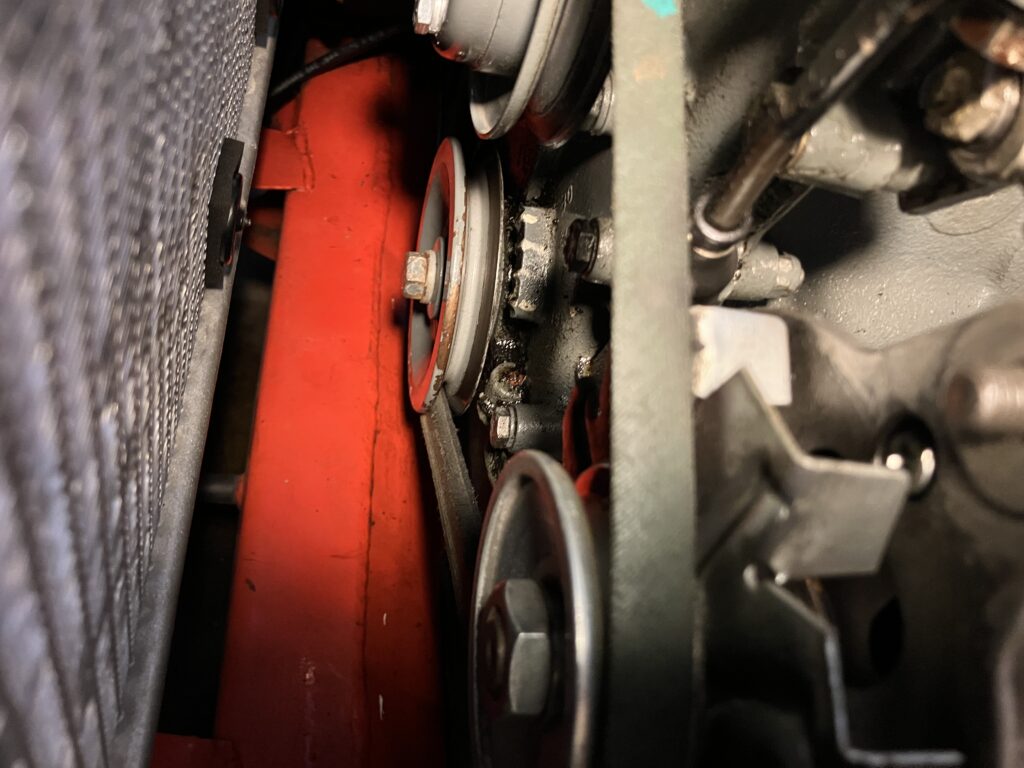

And I immediately found a couple of roadblocks. The first was that the crankshaft pulley of the car’s Lotus-Ford Twin-Cam engine has only a single groove, and despite apocryphal reports that old mk1 Escorts had a smog pump that was run off a compatible two-groove pulley, I never found one. The second was that, even if I had a two-groove pulley fabricated, there appeared to be no click-and-buy source of a compressor bracket to mount something to the engine. And the third was that the tiny engine compartment didn’t appear to have room to host a compressor. I pored over the Lotus Elan forum and found that the three examples of air-conditioned Elan +2s all used custom pulleys and brackets, and either relocated the alternator to the right side of the engine or mounted the compressor above it. Initially, none of these two roadblocks sound like showstoppers, but I’m neither a draftsman nor a machinist, machine work is expensive here in the Boston area, and without drawings for either part, it’s difficult for me to imagine getting the parts custom-fabricated and correct for less than $500 each.

One groove is all you get.

And then I thought… no pulley? No bracket? Very little room to mount it? An electric compressor would solve all three of these problems. And at only $220, the cost of being wrong is low. And, as far as the possibility that it would never be able to cool off a heat-soaked interior, I admitted to myself that none of my retrofitted a/c systems actually do that, all of them rely on the evaporator events being aimed directly at your face, and the only way to know how well a small electric compressor would work was to try one. So I internally green-lit the project.

Of course, any a/c retrofit involves more than just the compressor. The other major components are the condenser mounted in front of the radiator, and the evaporator assembly inside the car. For the condenser, I was fortunate that someone on the Elan forum identified the biggest one that would fit. $50 to Amazon, relocation of the cooling fans, and fabrication of brackets later, and it was done.

The condenser is one of the easier parts of the project.

For the evaporator assembly, I read on the Elan forum that one fellow installed the exact same Vintage Air Gen II Mini system that’s become popular for the 2002, but in order to install it, the fragile wood dashboard and the Lucas rats-nest of wires has to be removed, and I didn’t have the stomach to do that. I elected to go with an under-dash unit that fits in the passenger side footwell. Vintage Air makes one that fits for $440, but I found one on Temu for the throw-it-away-if-it-doesn’t-work price of $48.

Not bad. We’ll see how well it works. And yes, the Elan +2 has a magnificent dashboard.

For the main act—the electric compressor—I did a lot of research. I found Classic Retrofit who sells electric a/c packages for vintage Porsches and other cars. They’re very pricey, but their website and videos gave the concept of an electric compressor a lot of credibility. All of these electric compressors appear to be Chinese-made, and it was difficult to determine who actually manufactures the ones flooding eBay for as low as $220, as they’re typically re-branded by the importer/vendor. I believe, though am not 100% certain, the one Classic Retrofit uses is manufactured by Guangdong Posung, and I found compressors that look just like it on eBay for as low as $400. I eventually corresponded directly on made-in-china.com with Dezhou Chuangtao, the manufacturer of one of the $220 eBay compressors, and got a quote for $185 shipped, but in the end I went with Florida vendor Qualy Air, telling them that if they sold me a unit for $200 and gave me technical support, I’d credit them in the articles I’m writing about the project for Hagerty. They agreed.

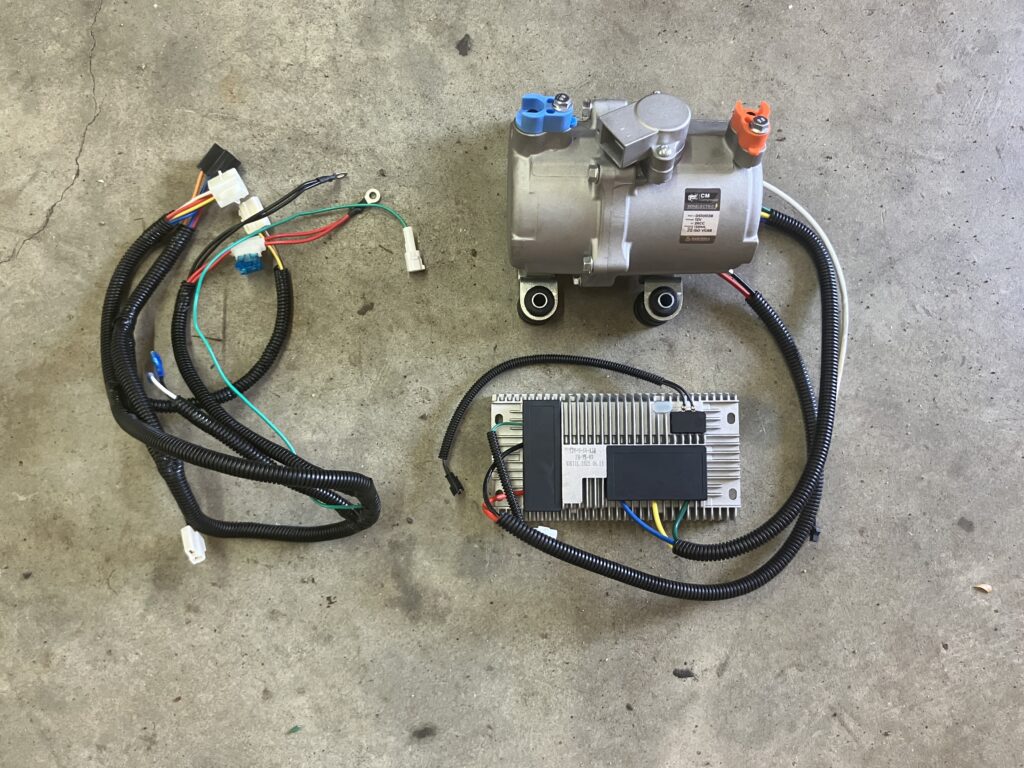

The compressor is even smaller than the Sanden 508 and its knockoffs that I use in the BMW world, but part of that is because the inverter is external. Other more expensive electric compressors like the ones from Guangdong Posung have the inverter as an internal component of the compressor, making the integrated unit larger.

The compressor, its inverter, and wiring harness. You can see that the inverter is as long as the compressor.

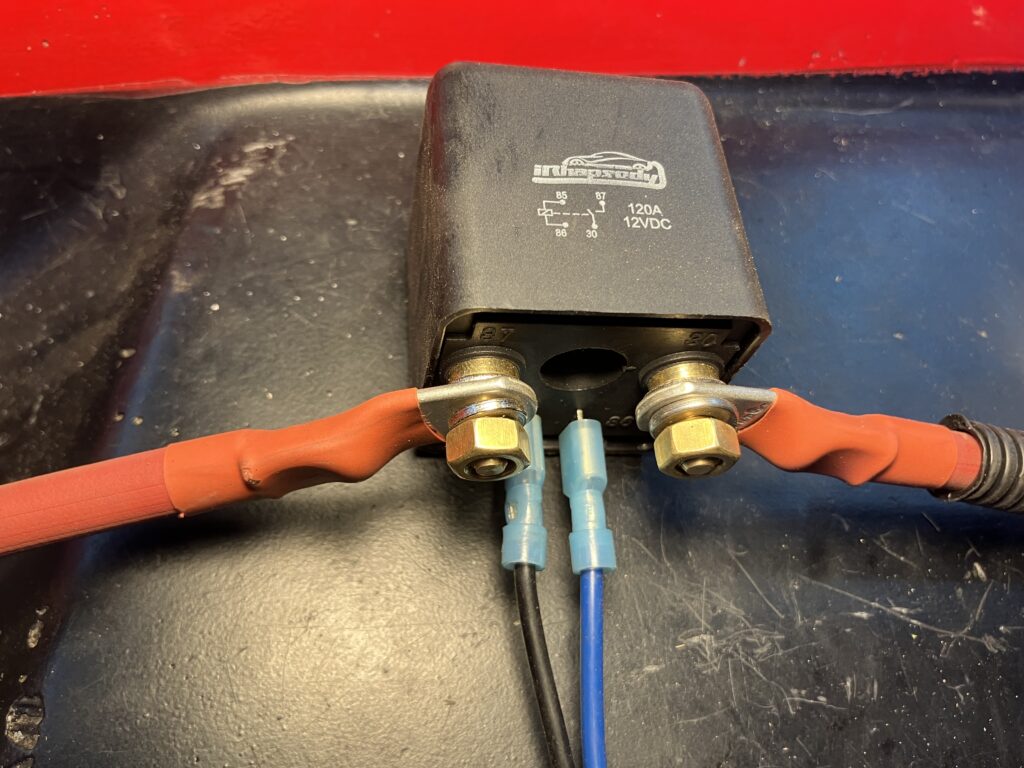

Of course, in order to generate 60 to 80 amps of current in a 55-year-old British car whose 38-amp alternator struggles to keep the lights bright and the wipers moving, a new high-output alternator needed to be installed, along with 4-gauge cables, an 80-amp Mega-fuse, and careful installation of a new circuit to keep the compressor-specific current from flowing through the ancient wiring and turning it into a toaster.

The 150-amp alternator. Be afraid. Be very afraid.

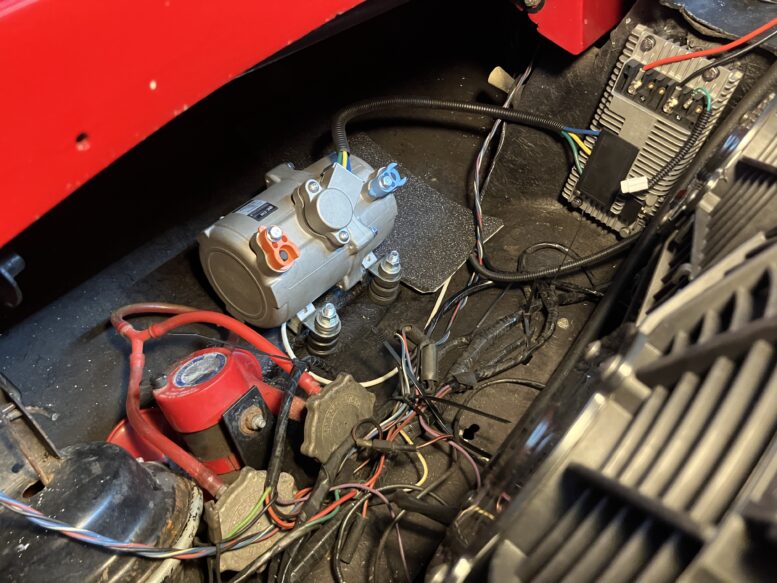

The 4-gauge wiring and relay that turn the compressor on.

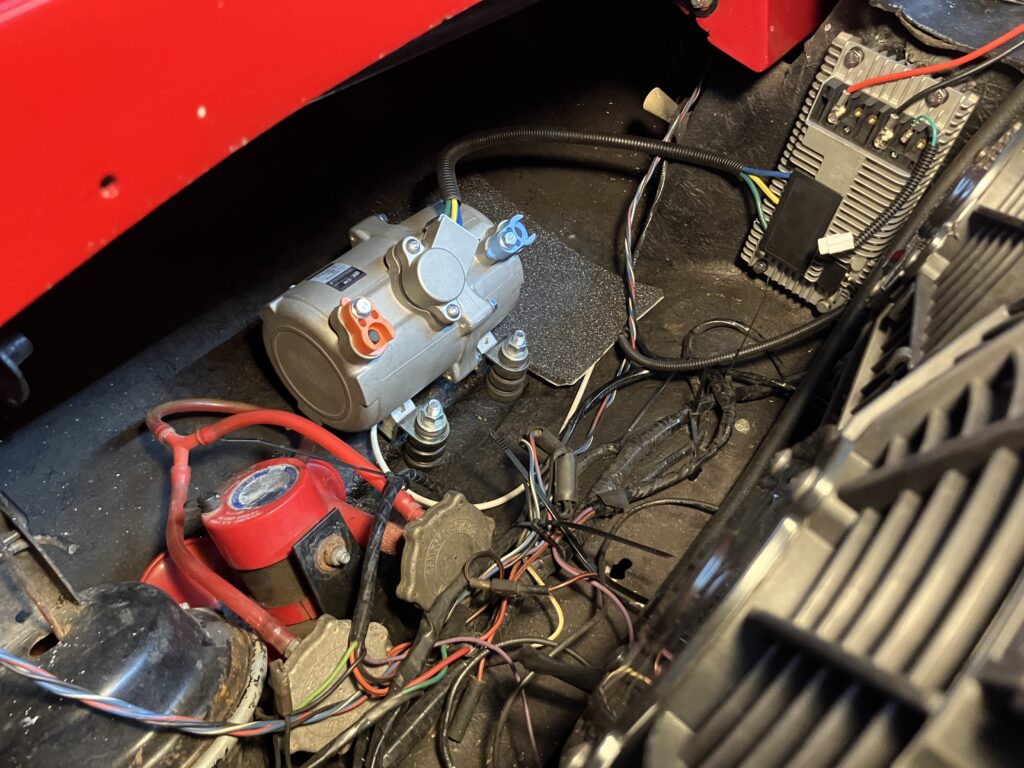

The idea that you can mount an electric compressor “anywhere” is a bit of a misnomer. It needs to be horizontal, and most engine compartments don’t have available flat spaces. YouTube videos of electric a/c installations often show folks mounting them in the trunk, and that made a certain amount of sense for the Elan +2 as the battery is there, but then you have to run the refrigerant hoses back and forth to the front. Fortunately, despite the Elan’s engine compartment being small, there was ample flat space in front of it in the nose. The inverter found a home on a vertical section of the nose wall.

This arrangement seems to work well.

So, the big components are now all installed. I’m finishing up the wiring and fabricating the hoses. If I can get it to the point where it’s buttoned up and I can drive the not-yet-air-conditioned little car through the lovely New England fall and re-engage the project in the spring, I’ll be happy. I’ll let you know how it works out.

Again, if you ask me the question “Should I do this on a 2002 or an E9,” my answer is a resounding “no.” Only the very early M10 engines don’t have a spare groove on the crank pulley, and even if yours is one of these, later pulleys are widely available (yes, a compressor-grooved pulley for a 2002tii is difficult to find). And compressor brackets for M10 and M30 engines are click-and-buy available from several sources.

But if you’ve got some small old car like my Elan +2 with zero support for a belt-driven compressor, hey, we’ve all done stupider things, right?

—Rob Siegel

____________________________________

Rob’s latest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books, including Just Needs a Recharge: The Hack Mechanic Guide to Vintage Air Conditioning. Signed copies can be ordered directly from Rob here.

Tags: air conditioning compressor retrofit