Last week, I gushed over the fall foliage, posted photos of my Signal Red E9 and my Chamonix 2002 against the on-fire trees, and promised to ditch the clickbait and get back to wrenching. I have done so.

Conspicuously absent from the “Rob’s cars in the New England fall” piece were the two other fun cars here at the house—Zelda the Z3 and the FrankenThirty. I hadn’t driven Zelda much in this gloriously colorful warm fall because the left front wheel had begun making a scraping noise when I leaned on the brakes. Plus, the car needed an inspection sticker, and I thought it was about even odds they’d hear the scraping braking noise when they pulled it into the inspection bay and fail it. The brake lining warning light wasn’t lit, but even that notwithstanding, I didn’t consider thin brake pads as the likely cause of the scraping sound because a) I could see by peering through the wheel spokes that the pads weren’t down to the metal, and b) even if they were, my experience has been that that usually manifests itself with almost any level of brake pedal effort.

I had this same grinding-on-hard-braking thing happen when I first began driving the Lotus Europa five years ago, and it turned out to be due to a newly purchased two-piston caliper having a stuck piston. This allowed the working piston to push the rotor off its axis of rotation and shove it into the other side of the caliper, which sounded like metal was being cut with a lathe. Since the noise and the circumstances of the Z3 were similar, I started looking at ordering a caliper and was happy to find that(they’re pretty reasonably priced. But then I thought, no, let me confirm that’s actually the problem.

I was glad I did because I immediately saw something I should’ve remembered—Z3s like every other modern BMW I’ve owned have single-piston calipers that slide on a bracket, so there’s no way that one stuck piston would shove the rotor off its axis like it did on the Lotus’ two-piston caliper. I did, however, see that the brake pads were surprisingly thin for the brake-lining light to not be burning.

When I looked at the pads and rotors closely, I saw the problem: The rotors had worn enough that there was a ridge near the edge, and the scraping was coming from there not being enough pad thickness to prevent that ridge from hitting the metal part of the pad.

Yup, those were thin pads.

I nearly ordered rotors, but in the end, I went for the inexpensive quick in-and-out solution—leaving the rotors alone and simply replacing the pads (I know you’re shocked). I got Zelda inspected, after which she safely and quietly joined in the leaf-peeping.

Next was a belt-related issue with the FrankenThirty. The fan belt that was in the car was stretched to the point that it was a bit slack even with the alternator at the end of its adjustment track. So when I sorted out the car after its purchase, in addition to replacing the timing belt and water pump, I ordered a new fan-alternator-water pump belt and a power steering belt. To my surprise, the new 965mm fan belt didn’t fit any better, despite my verifying on E30 forums that the length was correct. Why didn’t it fit? What was the problem? Was it due to its Franken-car past? Don’t know. But to deal with the problem, I ordered a slightly shorter 960mm belt, but hadn’t gotten around to installing it yet. Now, with the first few cold fall mornings under the car’s, uh, belt, there was some squealing on starting from the fan belt, as well as some groaning from the power steering. In addition, even on a driveway that has the patina of decades of leaks on it, the nightly spotting of power steering fluid from the E30 was beginning to bother me.

Both my E39 and my Nissan Armada tow vehicle do this too, but they live at the end of the driveway.

So, belts and power steering fluid leaks it was. I pulled out the airflow meter and filter box to allow access to both systems.

The first thing I did was tangentially related—I prophylactically examined the voltage regulator. Even though the FrankThirty’s alternator appeared to be charging the battery, these things can suddenly quit working if the brushes are worn down. All it takes to pull out the regulator and inspect its brushes is undoing two Phillips-head screws. If the brushes are worn, it’s usually completely obvious, with the height of the two brushes uneven, and one worn down to the height of a pencil eraser. These looked fine.

Good to go.

Next was the fan belt. The tooth-and-gear belt adjusters on the E30 are a step up from the more primitive system on the 1970s-era cars, but the alternator is mounted lower down, and the nut and bolt for the mount on which it pivots is challenging to access. This was important because the 960mm fan belt was too short to be slid onto the pulleys even with the alternator rotated as close as possible to the engine on its adjustment track. I needed to instead employ the old-school trick of unbolting the alternator, passing the belt around its pulley, then re-mounting it. This was surprisingly time-consuming because the shorter belt fit with slightly less than zero clearance, causing the alternator’s pivot hole not to line up with the holes in the bracket holding it. But I got it in. It’s my assumption that the belt will stretch and use more of the adjustment track.

This was a surprising pain.

That left the power steering fluid leaks (well, it’s really automatic transmission fluid, but po-tay-to po-tah-to). This system uses rubber hoses held onto metal fittings with Oetiker crimped-on clamps that you can’t simply tighten with a screwdriver. When they begin leaking at the ends, as long as the hose itself isn’t cracked or mushy, you can cut the clamps off and replace them with decent worm-and-screw clamps that you can actually tighten.

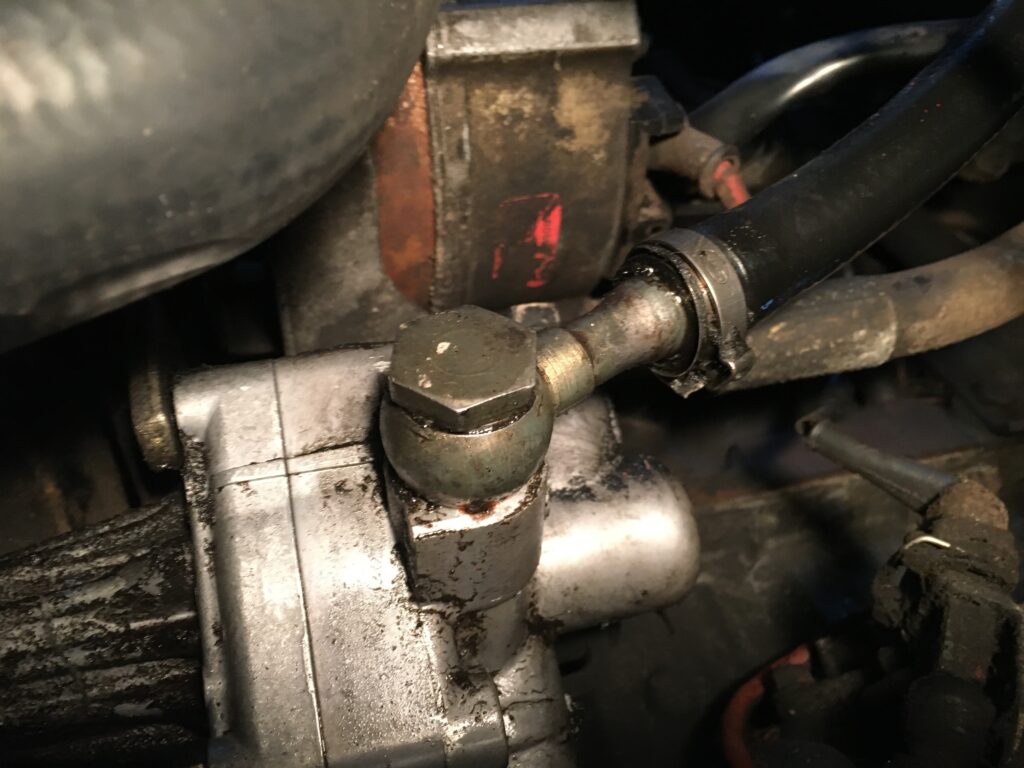

You can see how the power steering fluid had gotten everywhere.

When I saw where the fluid was leaking, I understood how the three-puddle pattern every time I moved the car was created by one set of leaks from the hose connections on the power steering pump, another from the fitting on the steering rack, and the biggest set of leaks running down from the reservoir, onto the frame rail, and dripping out a drain hole near the pedals.

The leaky frame rail caught in the act.

The dirty down-under of the steering rack.

One of the four Oetiker crimp-on clamps had already been replaced with an adjustable one. I replaced the other three. It was even possible to do this without pulling the hoses off and dumping the fluid by opening up the worm-and-gear-style clamps, wrapping them around the hoses, and re-fastening them instead of sliding them over the hose ends.

Before…

…and after

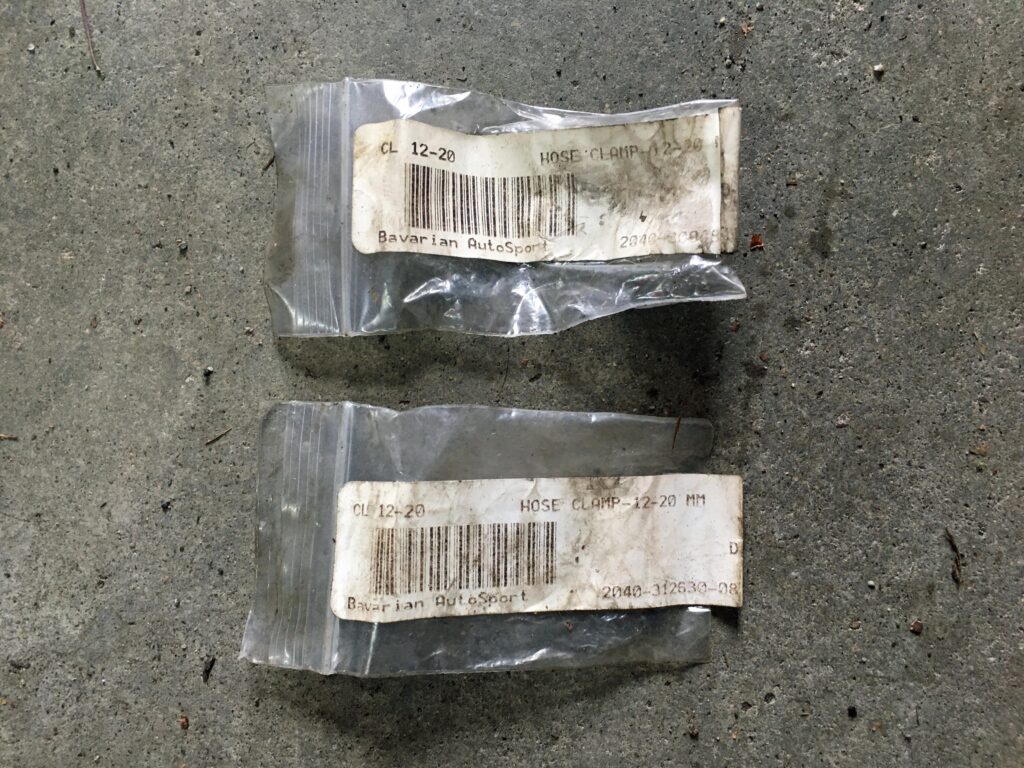

There was an unexpectedly poignant moment: When I did this, I used up the last of what once seemed like an endless supply of 12-20mm OE-style that I’d bought years ago from dearly departed Roundel advertiser Bavarian AutoSport.

Funny the things we have emotional reactions to.

With the belts tight and the car doing less of a power steering Valdez, I took the FrankenThirty out for his foliage shot.

Red on red. Yum. I suppose the red power steering fluid would’ve matched the leaves AND the car.

I really should give the 2003 E39 530i the same power-steering-fluid-leak-stanching treatment, but I suspect that it also needs to have the power steering pump replaced, as when the temperature drops, it gets very difficult to turn the steering wheel first thing in the morning. One of the advantages of working from home and good weather is that the supposed daily driver has barely been driven the past few months. This too, I’m sure, shall pass.

—Rob Siegel

____________________________________

All eight of Rob’s books are available here on Amazon. Signed personally-inscribed copies can be ordered directly from Rob here.