I’ve had my new-to-me 1998 M3 sedan with five-speed-manual, which I’m calling Project Concord, for a little over a week now. So far, I feel like it has been a comedy of errors and mostly self-inflicted pain. But I’m learning, and despite more steps backwards than forwards, I’m fixing things and making overall improvements to this already-nice and surprisingly clean E36.

If you recall, I introduced a problem with the passenger rear door when I picked the car up in North Carolina. After using the remote key fob to lock and unlock the doors, it was stuck shut and couldn’t be opened from the inside or outside. Even pulling the lock plunger up from inside the car did nothing. I believe this is called “deadlocked.” I had managed to temporarily fix this when I arrived home.

I say “temporarily fix” because the next day I managed to deadlock both rear doors. So this four-door sedan had become less practical than my two-door E30. While trying to “un-stick” the rear doors, I encountered the familiar scenario where the sunroof automatically opens–thankfully it wasn’t raining this time. However, when I went to put the sunroof back into the closed position, it too became stuck. Joy. I really despise sunroofs.

In addition to the door and sunroof issues, I had uncovered a failing trunk wiring harness, with evidence of a previous repair, and the electric front seats’ recline functions weren’t working, which was a known issue. While I could hear the recline motor working on the passenger side, I heard nothing on the driver’s side. I really despise electric seats.

This trunk harness has seen one repair too many. There’s not much that can be done when the wires and insulation come this weak and brittle.

At this point, I decided to head back inside and do some research before I continued to break more things. Here’s what I learned:

- E36s (and presumably anything with a wiring harness that feeds into a trunk lid) have issues with the trunk harness wiring breaking at the “bend” point, which can cause problems with central locking and a number of other things.

- If lock actuators fail on a door that can’t be locked or unlocked with a key (like the rear doors), they will be stuck shut. If you’re lucky, with enough lock and unlock sequences the lock actuator will muster enough energy to unlock, allowing you to rip them out with a vengeance with open-door access.

- The electric sunroof motor has an external Allen head that can be rotated to manually operate the electric sunroof.

Armed with this new knowledge, I had hope that the lock issues were related to the failing trunk wiring harness. Thankfully BMW sells a repair harness, complete with all (most) of the necessary connectors, that can be spliced into the car’s main wiring harness in the trunk area (part number 61128391788). And on the seat-recline-functionality front, Odometer Gears sells replacements for the problematic, small, plastic seat recline gears that tend to fail. I’d replace those first and then deal with the recline motor on the driver’s side.

The first order of business was to manually close the sunroof! The trays and drains were clear, so actually fixing its normal electric operation was low on my list of priorities—I just wanted it closed so I could drive the car. With the small sunroof motor cover removed, I was able to manually rotate the motor with a ratchet and Allen-head socket, closing the sunroof. Sheesh.

The sunroof motor removed so that the power could be disconnected until a permanent fix can be made.

Meanwhile, I had reached out to a local friend and BMW expert, Marshall Lytle. Marshall is a BMW CCA member, an experienced racer, and an experienced BMW builder/maintainer. For those who have attended National Capital Chapter’s Virtual Garage Series, Marshall has previously shared his workshop and some of his cars. He has a number of cool BMWs including an S54-swapped BimmerWorld-built 1995 M3 race car (E36) and is the original owner of a Techno Violet 1997 BMW M3 sedan with five-speed-manual (also E36), so he’s very familiar with the E36 chassis. Marshall was kind enough to invite me over to inspect my new project in his workshop and assist with the trunk harness replacement.

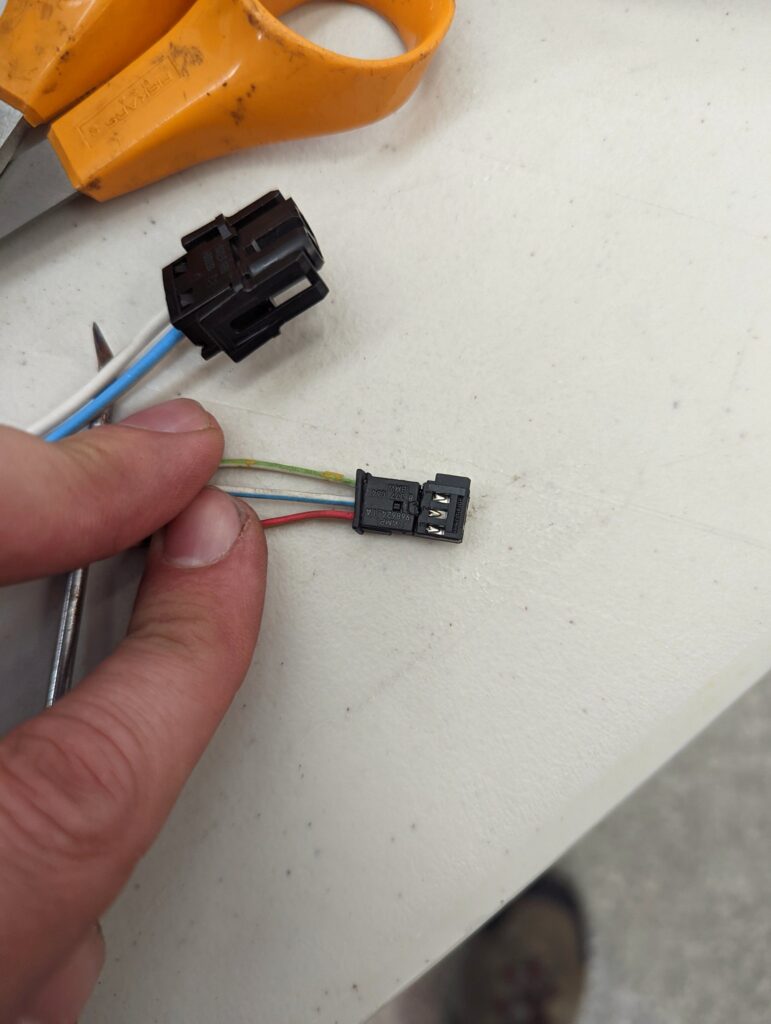

The new trunk harness arrived in the mail the night before going to Marshall’s workshop. There were seventeen wires, but only ten were to be spliced into the car’s harness. The other seven were for E36 accessories that my car didn’t have. I spent a little time with a multimeter tracing and labeling wires, determining which needed to be used and which needed to be taped aside. Five of the seventeen wires were the same brown color, so this was actually necessary.

I arrived at Marshall’s workshop early on Saturday. He put the car up on the lift and gave it a mostly clean bill of health. There was a minor leak where the lower radiator hose connected to the radiator, which was date-stamped 2011, the rear sway-bar endlinks needed replacement, the transmission mounts needed replacement, and the power steering hose should be replaced/updated as it’s a common E36 failure point.

The harness replacement went smoothly with Marshall performing the splicing work in the trunk while I snaked the other side of the harness through the trunk lid and hooked up the trunk light sensor, license plate lights, and central locking. Only one connector from the original harness needed to be de-pinned and reused for the new harness. Jim Gerock stopped by and lent a hand as well. When all was said and done, and with Marshall’s M3/4/5 used for reference when needed, the new harness was in place. Unfortunately, this did not resolve the central locking issue as the rear doors were still deadlocked. It did resolve intermittent license plate lights and the previously inoperable trunk light, so positive progress was made!

Three down, seven to go. We cut the old trunk harness short, giving plenty of extra wiring to perform the splicing outside of the trunk for easier access.

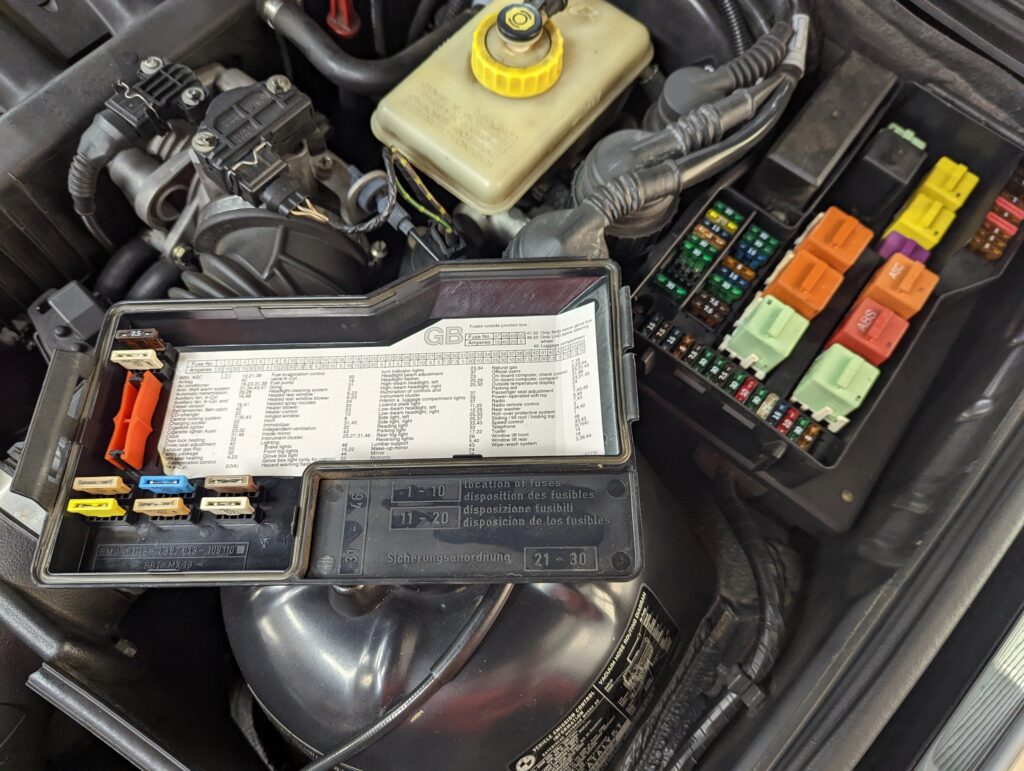

Later that day, after U9 soccer tournaments and I was back home in my garage, I decided to do something on the E36 that I had done on my E30 nearly seven years ago—replace ALL of the fuses. I did this on the E30 after realizing the majority of the fuses weren’t in the correct places and some had blown. My E36’s fuse box looked fairly tidy, but based on this style of blade fuses, it was hard (for me at least) to tell if any were bad. After replacing nearly 50, guess what happened? The driver’s seat recline motor started functioning and, most importantly, one of the rear doors finally unlocked. Coincidence? Maybe.

At this point, I went to town locking the car manually and unlocking it with the remote, hoping that I wouldn’t introduce the deadlock situation again. And after what seemed like an eternity, I heard the sound of the other rear door’s lock actuator groan. While it didn’t unlock the door, it did resolve the deadlock problem, allowing me to manually pull the lock plunger from inside the car. Four functioning doors–how about that? My son later commented that he heard me excitedly cheering the garage and asked what had happened. The E36 Gods had smiled upon me, if only for a brief moment. I realize that the issue with the rear door locks is likely failing lock actuators, which are on order. So, until the replacements arrive, I’ve removed the failing actuators and will lock/unlock the rear doors manually. I only managed to break one special-order plastic part, one door clip, and de-skin my thumb in the process.

The lock plunger pivot and self expanding rivet are made of plastic. Brilliant! (Not pictured, the one that exploded when trying to remove the plastic screw.) Yeah, I didn’t need that skin on my thumb anyway.

On a tear of small successes, I decided to have a go at fixing the driver seat’s recline functionality. This was actually the third time I had the seat out. The first time I took it apart to determine what gear I needed to order. The second time I took it apart to manually set the seat back to a position of my liking. Would the third time be the charm? Indeed it was. Having the right assortment of tools readily accessible, I was able to take the seat out, take apart the motors and gearbox, and have the seat back in the car within 30 minutes. Practice makes perfect.

Of course, it couldn’t be all rainbows and sunshine. While removing the driver’s seat, I noticed a few fluid drips on the clutch stop. Yes, there was a small leak from the clutch master cylinder. You can’t win them all, I suppose. But with four functioning doors and a driver’s seat positioned to my liking, I could take my kids out for a spin, which I did. And as it turns out, they love the Active Autowerke exhaust and Boa Boa interior as much as I do.

What’s next? A new clutch master cylinder, new radiator, new rear lock actuators, new rear window regulators, and fixing whatever else I break in the process. And driving. Lots of driving. —Mike Bevels