The next step in making Bertha the knock-around-drive-during-winter-if-there’s-no-salt-on-the-roads 2002 (which is, not coincidentally, what it already looks like anyway) is to get the heat working. This had two components—getting the heater valve to turn on from inside the car, and dealing with the dead blower fan in the heater box. I expected the first of these to be pretty easy, and the second to be a metric crap-ton of work.

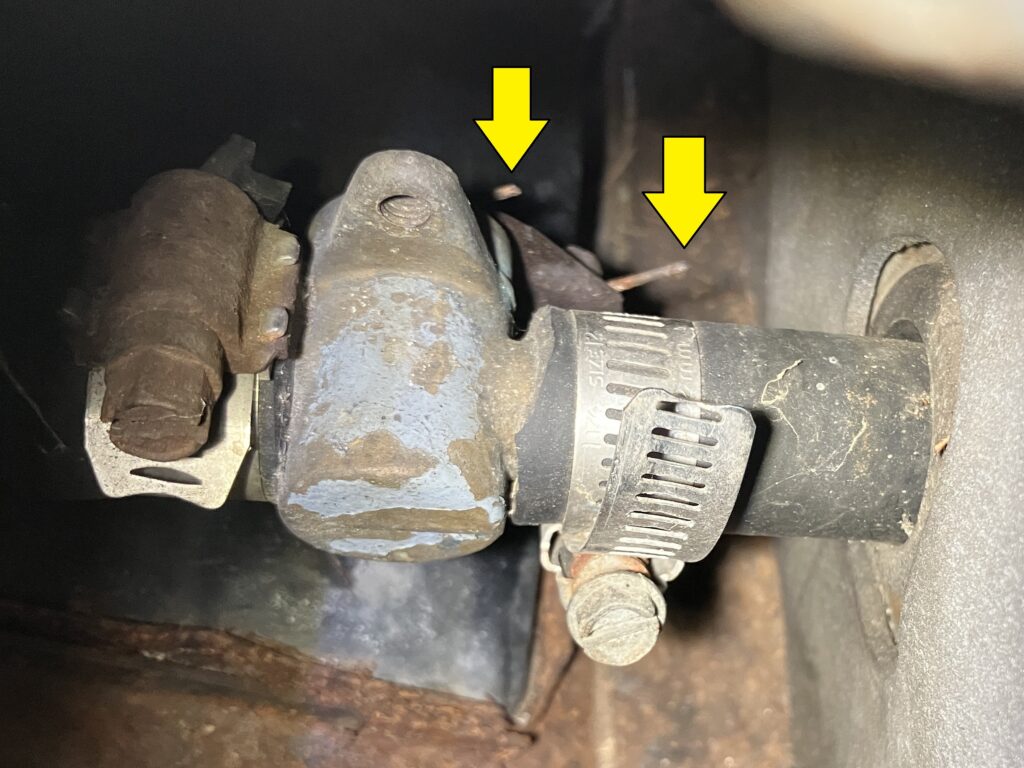

As I mentioned a few weeks ago, the issue with the heater valve was that the Bowden cable controlling it had snapped. Peering into the under-cowl area from the side, I could see the valve, the lever on the back side, and both snapped-off ends of the cable.

No mystery here.

The lever rotated freely between its off and on positions, so really all I needed to do to get heat was set it to the on position and leave it there for the duration of the winter, but we all know how heat in cars can go from “help me lord I’m freezing” to “Enough! I’m roasting! MAKE IT STOP!” Plus, having owned E9s, E3s, and E24s whose heater box is plumbed always-on, I know how heat continues to pour out of the box even when you have the flaps closed. So if there was an arthroscopic way to stitch the cable back together, I wanted to find it and employ it. I searched on Amazon and found these little barrel-shaped “wire rope clips” that had a hole in both ends and two little Allen screws to tighten down on the ends of the cable. Perfect, I thought—stick one of these between the broken ends, and Bob’s your uncle.

The right kluge for the right job?

Although it seemed trivial, I couldn’t maneuver the barrel into position on both cable ends, so it made sense to me to undo the far end of the broken-off cable, take it out of the car, stick the barrel on it, slide it over the long end, then reassemble and snug everything down. Unfortunately, the little 7mm nut on the end of the lever wouldn’t surrender its 50-year-long death grip, and I could feel its corners beginning to round off it. No problem, I thought—I’ll just undo the little bolt holding the lever onto the valve instead.

I put some torque on the little 7mm wrench, and experienced that sickening feeling you get when a fastener suddenly gives way without going through the screeeee portion of the loosening process. The bolt and the little cylindrical end of the valve it screws into had snapped clean off. D’oh! In retrospect, I clearly should’ve soaked both 7mm fasteners in Silikroil before beginning this operation. Fortunately, the lever itself remained attached to the valve (it’s probably rusted onto it), so at least for now, it can still be used for winter-on / summer-off heater core operation.

What is snapped can’t be un-snapped.

Next was the issue of the blower fan. I wanted it operational not only to keep my feet warm, but also to keep the windshield defrosted. Unfortunately, to replace the blower fan on a 2002, the heater box has to come out, which is a substantial operation. Further, this car has dealer-installed Behr air conditioning, so that would have to come out in order to pull the heater box. When I revived the car six years ago, I made the rash decision to rebuild the a/c but leave the heater box alone, essentially sticking a thumb in my own eye regarding the whole “while you’re in there you’d be an idiot not to do both” thing. So, yeah, I’m an idiot.

The first thing to do when faced with a non-functional 2002 blower fan is to make sure it’s, to quote The Wizard of Oz, not only merely dead, but really most sincerely dead. It can stick from lack of use, and sometimes, surgically-sprayed Silikroil and a nudge can free it. You can reach under the cowl and poke something like a popsicle stick through the plastic lattice and try to turn the fan blades to judge if it’s seized. I found that Bertha’s fan was completely free. So maybe there was hope.

A good view under the cowl of the fan and the plastic heater box lattice it sits behind, this one from Louie my ’72 2002tii. You can see the shiny new fan motor in it, installed when the heater box was removed and rebuilt—work I’d only do on Bertha if it was absolutely necessary.

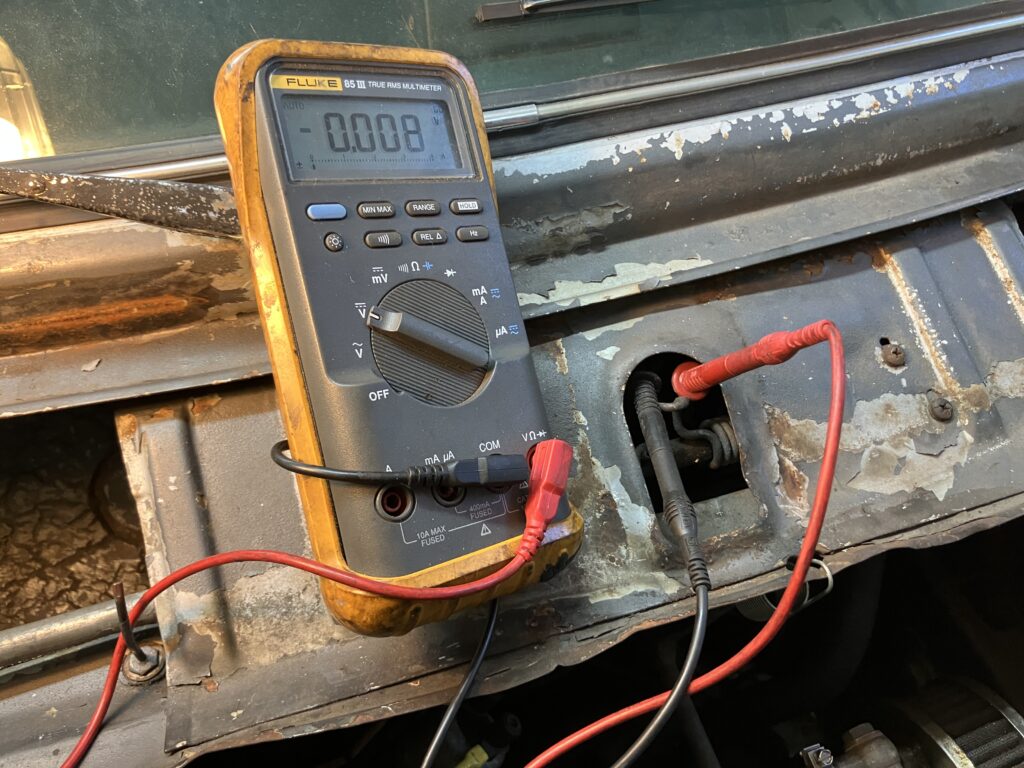

The next step was to see if the fan is getting voltage. I connected the battery, clicked the key to the ignition position, moved the blower fan slider on the dashboard to high, and carefully positioned my two multimeter probes through the hole in the middle of the cowl cover and on the terminals. I was surprised to find there was no voltage at the motor. This usually isn’t what happens. As I described here, when I was readying the Bavaria for sale this summer and wanted to address its dead blower fan, I found that the fan turned freely and there was voltage to it, but it was still clearly dead. I removed it and found that the brushes had seized up in the rectangular channels they slide in, so they weren’t making contact with the rotating armature. I was able to free them and resurrect the fan. (So it wasn’t most sincerely dead :^) Unfortunately that trick wouldn’t help me here, because the Bavaria, like the E9, E30, E24, and most other cars, has the huge advantage that the blower motor can be withdrawn from under the hood.

As the husband said in the old Kellogg’s cereal commercial, nuttin’ honey.

When the fan isn’t seized and there’s no voltage to it, there are two paths to take. One is to see if there’s an easy answer to why there’s no voltage. The other is to temporarily hot-wire the fan directly to the battery and see if it springs to life. Normally I would do the second one first (I always want to jump to the end of the mystery and know if I need to put a replacement component on order), but the lack of voltage surprised me, and would need to be fixed anyway to have a working fan.

I thought the most likely culprit would be the contacts on the slider switch on the dash, which would be a bit of a pain to deal with. I mean, there was effectively zero chance it could be something as simple as a popped or non-contacting fuse. I would’ve seen that six years ago.

Wait, I WOULD’VE seen that six years ago, right?

One of the many odd things about Bertha is that, at some point before I bought it in Austin the spring of 1984, someone had rewired the fuse box and paid little attention to the original numbering, so what circuit is on what fuse is always a mystery. I squeezed each fuse from the contacts at the ends while rotating them around to make sure that the contacts weren’t either loose or dirty. While I was doing this, I inspected each fuse. A break in the middle of the little gold-colored metal strips is usually really easy to see against the plastic of the fuses. I didn’t see anything, and mentally replayed the “You didn’t think it was gonna be that easy, did you? / You know, for a moment there, yeah, I did” scene from Kill Bill. (I guess I’m in movie mode today.)

I was about to move on when I thought “Let’s be certain.” I set the multimeter to measure resistance and to beep when there’s continuity (meaning very low resistance), and one at a time, put the probes on the ends of each fuse. Beep… beep… beep. I got to fuse #11 and… silence.

Gotcha.

You!

I looked carefully at the red 16amp fuse, and saw what looked more like a crack than the characteristic melt-through of a blown fuse.

See it? No? Neither did I.

I replaced it with a new 16amp fuse, and the blower fan squeaked somewhat reluctantly back to life. I was stunned.

Now, let’s be clear. There are usually multiple reasons to rebuild a heater box. The most acute is when the heater core is leaking, as was the case with Louie (the Ran When Parked car). Actually, I take that back—the most acute is when there’s rodent contamination, and any air flow through the box, including fresh air flow, is gag-worthy. But on a 50-year-old car, it’s certain that the foam has long since worn off the flaps, so even when the flaps are closed, gobs of air are getting past them. This means that, in the summer, hot humid outside air streams in and fights your hard-won working air conditioning, and in the winter, cold air fights the heat. So, when you remove the heater box for any reason, you clean it, re-line the flaps with new foam, and make bloody sure the fan works without squealing. So, in finding that my fan actually worked, and without any rodent stink or heater core leakage, I’d taken heater box removal and rebuilding off the table.

Louie’s heater box when I rebuilt it in 2017 due to a leaking heater core. Remarkably, it didn’t smell like rodent. I wouldn’t be in the least surprised if the inside of Bertha’s looked similar. And I’m glad that, for the moment, I don’t need to find out.

So. Bertha now has binary-under-the-hood-switched-on-and-off heat fighting for dominance against a fair amount of cold air coming through the degraded foam on the flaps, and a working though squeaky blower fan. Given where we are at the end of 2025, I’m calling it success and taking the win.

—Rob Siegel

____________________________________

Rob’s newest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.