Last week, I did the easiest E39 front-end repair possible—replacing the sway bar links. With less than an hour’s work, including setting the car on jack stands, this eliminated a longstanding thunk-and-clunk. Feeling insufferably pleased with myself, I set my sights on the next annoyance—a front wheel shimmy that had gradually gotten worse.

The shimmy seemed to be coming from the left front wheel, was present during braking, was most obvious at low speeds, and didn’t cause the brake pedal to pulsate. Shimmys that do cause the pedal to pulsate are almost aways due to what people often call “warped rotors,” but when I wrote for Road & Track, I was roundly slapped down for using that phrase, as rotors rarely actually warp, and instead the mechanism is almost always microdeposits on the rotors. I looked at the E39’s parts receipts and saw that the rotors were only about two years old, but hey, the car sits outside and sometimes isn’t driven for a few weeks, so anything’s possible. Shimmys can also be due to bad ball joints and/or rubber bushings in the lower and upper control arms, but I’d replaced those with Lemforder parts since I bought the car. That was eight years ago, but I doubt the car has clocked up 10,000 miles since them.

I jacked the car up, spun the wheels, grabbed them at 12 and 6 o’clock and at 3 and 9 and did the push-pull thing, and didn’t feel any steering play that would cause a shimmy. So I pulled off the wheels so I could spin the rotors by hand. I found that, on the left side, the rotor appeared to cyclically drag on the pads as I rotated it around. Was it “warped?”… I mean had micro-deposits? Maybe. Despite the lack of pedal pulsation, a less-than-true rotor fit the shimmy symptom well enough that I jumped onto Rockauto to see if I could find an inexpensive set of rotors. To my delight, there was a manufacturer closeout on a set of front rotors that got them shipped to my door for $67. I ran the part number and they appeared to be Carquest-branded rotors sold by Advance Auto Parts and manufactured by Raybestos. Good enough.

While I was waiting for the rotors to arrive, I pulled the calipers off so I could squeeze them and make sure they weren’t sticking. Then I yanked the rotors off just to make sure I wouldn’t get tripped up by the little recessed Allen-key set screw being seized. Then I reflexively spun both hubs. When I did, I was surprised to find that the one on the left side was clearly bad—dry, slightly rumbly, and with a cyclic grabbing you could plainly feel.

Giving the hex bit going into the Allen-head rotor set-screw a little tap with to make sure it’s seated before squeezing the trigger on the impact wrench.

And then I realized: It’s probably not the rotor that’s causing the wheel shimmy. It’s probably the bad wheel bearing. Never had that happen before.

If you’re like me, when something like this happens, you drop the tools, run back into the house, clean your hands just enough to be able to use the laptop, and put the part you need on order as quickly as possible. I went first to FCP Euro, as their proximity in CT means that, if I order a part in the morning, it usually arrives in a day or two. They showed genuine BMW wheel bearings at nearly $400 per side. Gulp. Their original equipment (OE) offering was a FAG wheel bearing at a still-hefty $145 per side. And it was Thursday afternoon, so delivery-wise, it was possible the part wouldn’t arrive until Monday.

So I went to Amazon. The only next-day wheel bearings they sold had brand names that likely appear and vanish like cold sores, and had a bump in one-star ratings of the form “Bloody thing began rumbling after a month.” Their decently-reviewed offering was a TRQ wheel bearing set for $100, but like the ones from FCP, it wouldn’t arrive until after the weekend.

So I looked on Rockauto. I didn’t expect them to have anything that would arrive quickly, but as was the case with the rotors, you never know what they’ll have on closeout. I saw a single front wheel bearing for $29 shipped whose part number mapped to API (Autopart International)—a brand you’d likely have installed if you took the car to a local “we repair everything” garage rather than to a specialty shop.

Now, there were a few dynamics at play here. One is that I’m usually smart enough to only buy a part of questionable quality if the repair involving it is easy (witness the $67 front rotors). But another is that being cost-conscious and practical vies with “do it once do it all.” Longtime readers may recall that about 15 years ago I had an E39 wagon, a black-on-black 1999 5-speed sport-package 528iT. When I bought it, it was the newest nicest car I’d ever owned, and I did the things you’re supposed to do. I first did a full-on cooling system replacement. Then, when the car needed one of the lower control arm bushings replaced, I did everything in the steering and front suspension, including the wheel bearings, which had absolutely nothing wrong with them, because that’s what you were supposed to do. I remembered them as being difficult, but I didn’t remember why. Nowadays, with the questionable quality of parts, I’m much more circumspect about replacing a part that’s not obviously bad, as there’s a very real possibility that you might remove a part that still has years of life in it and replace it with something inferior. And regarding automatically doing both sides, if a car needs front struts or rotors and pads, obviously I’d still do both left and right, but for other parts, I’ve dialed that back. The right wheel bearing was fine. Why spend the time or the money on it?

My ’99 528iT was a beautiful but needy car.

All this manifested itself in my looking at Rockauto’s closeout $29 API wheel bearing and thinking “They have only one. I need only one. How bad could it be?” Again, it wouldn’t get here any quicker than any of the more conventional options, but it cost a fraction of any of them.

While I waited for it to arrive, I had at the wheel bearing. And why it was a challenging repair 15 years ago immediately came flooding back.

The front wheel bearings on an E39 aren’t like they are on a vintage BMW where the bearing races are press-fit into a hub that the rotor bolts onto and that slides onto a stub axle and is held there with a castellated nut. Instead, the bearing and hub together are a replaceable pair that bolts onto the steering knuckle. It’s held on from the back by four 18mm bolts. The problem is that access to the front two of these bolts are partially occluded by the bottom of the strut housing. And all four of the bolts are installed with Loctite at the factory, so if you simply put an impact wrench connected to a compressor pumping out 130psi, or a breaker bar with a pipe on the end, you risk snapping the bolts, and if you do, you’ll be in a world of hurt. You can reach the the two rear ones with a thick-walled 1/2-inch impact socket and see if they’ll budge, and you can reach the top front one with a 3/8-inch thin-walled socket, but to get at the bottom front one, you need to loosen the pinch collar and slide the whole knuckle assembly down the strut. You can web-search to find a handful of tricks to all this, but I used my oxy-acetylene torch to heat up the protruding ends of the bolts and the aluminum around them, as I really really didn’t want to break any bolts or round the heads off.

What a pain.

And I wound up having to press the tie rod end out and undo the bottom of the sway bar in order to get the knuckle to move enough to allow access to the bottom front bolt.

Maybe others haven’t needed to do this, but I did.

I was glad to get this off without damaging anything.

Sweet success.

While waiting for the wheel bearing, I did some R&R on the dust shield. It’s held onto the knuckle with four M8 bolts with conventional 10mm heads, but for some reason the rear-most bolt has a Torx head, and rust always seems to form between the washer behind it and the shield and cause the shield to break free and rattle. I could see where, when I’d replaced the rotors a few years ago, I’d put a rubber o-ring behind the shield to stop it from rattling.

Why they use a Torx bolt here I have no idea.

This time I removed the Torx bolt and replaced it with a conventional 10mm-head M8 bolt and a washer.

Even with heat, it didn’t come out without a fight.

Much better.

There was also a separated rivet on the part of the shield that surrounds the bearing itself. I drilled it out and replaced it with a small nut and bolt held with a dab of Loctite.

Forestalling a tinny metallic vibration.

While I was doing this work, I noticed that when the front struts were last replaced, the mechanic didn’t bother to rotate them so the little alignment pointer on the bracket was sitting in the gap in the pinch collar like it should be. I looked on the other side and saw that it was the same way, meaning that both the steering knuckles were sitting too far down on the struts. I made a note that, come reassembly, I should fix it on both sides.

That should be around the back in the crevice of the pinch collar.

When the wheel bearing arrived around lunchtime on Monday, I opened the package, spun it, and it was immediately obvious the thing was junk. It didn’t feel any better than the one I’d removed. I felt like an idiot. While I didn’t need to use the E39 for anything, it was occupying precious garage space when it should’ve been in the driveway like a daily driver is supposed to be.

I could say “you suck,” but I had no one to blame but myself.

I went back online, but to no one’s surprise, nothing that could arrive via next-day delivery suddenly appeared on Amazon that wasn’t available before the weekend.

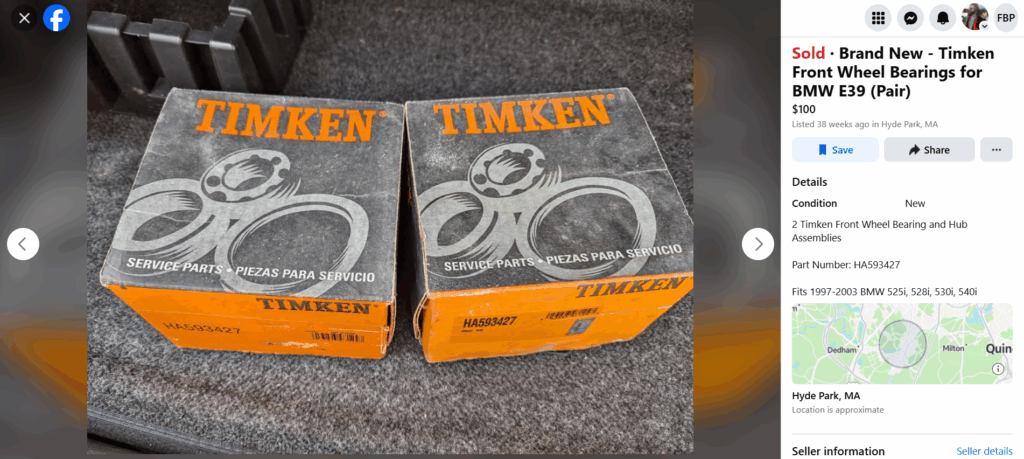

Then I threw a desperate hail-Mary pass—I checked on Facebook Marketplace. To my surprise and delight, there in Hyde Park (35 minutes from me) was an ad for a pair of Timken bearings for an E39 for a hundred bucks. I was intrigued.

Hmmmmn.

I googled the part number on the Timken box, and something unusual came up—that there was a run of Korean-made Timken E39 bearings that didn’t have the hole for the rotor set-screw countersunk. I messaged the seller and asked him a) what the story was with the bearings, b) to send me a photo of this hole, and c) to check if the bearings spun without any noise. He said that he’d bought them ten years ago from Pelican Parts for a 540i that had gotten totaled before he had the chance to install them, that he’d moved them between four apartments and houses, that he’d had them up on Facebook Marketplace for nearly a year, and that I was the first response. Regarding the bearings’ condition, he said that one of them spun flawlessly but had a small amount of corrosion on the outside of the flange face, and the other one had the smallest little hitch in the rotation.

“So… fifty bucks for both?” he said.

“Can I come look at them right now?” I asked.

40 minutes later, I was at his door. I had the removed wheel bearing with me, as well as the rotor set screw, to be certain. It all checked out.

I got the bearing home and, before I installed it, noticed something I didn’t at the seller’s house. On the inside of the flange, it clearly says “FAG.” So they’re not Timken bearings. They’re OE FAG bearings, for 1/6th the cost of what they would’ve been through FCP Euro. And the “hitch” in the rotation of the second bearing is tiny. If the bearing on the right side ever goes bad, I’d install it without hesitation.

Booya!

In a surprising bit of synergy with the wheel bearing replacement on the E39 wagon 15 years ago, I had a flashback of having a set of eight BMW bearing bolts with factory Loctite on them stashed somewhere because I ordered them not knowing that the set of bearings I’d ordered also came with the bolts. Incredibly, I’d kept it with some other E39 parts that stayed together in a box, and was able to lay my hands on them. I used three of the new bolts. The pesky bottom-front bolt whose access is occluded by the bottom of the strut had to be reused, as I was never able to drop the steering knuckle far enough to fully withdraw it. I put fresh Loctite on it and called it good enough.

Booya a second time! Who’s a good pack rat?

Once the bearing was installed, I rotated the strut to position the alignment pointer in the groove of the pinch collar, slid the collar up on the strut, and tightened it down. Then I did the same on the other side.

This was before the collar was moved back upward and the pinch bolt tightened.

And with that, Operation Unexpected Wheel Bearing Replacement was complete.

This made me feel so much better.

Part of me wanted to throw the old set of rotors back on so I’d know beyond a shadow of a doubt whether the cause of the wheel shimmy was the bearing or the rotors (or both), but just because I said that replacing rotors is easy, that doesn’t mean that I have any desire to do it if it’s not necessary. On went the new rotors and the calipers. On went the wheels. A drive around the block revealed that the shimmy was gone.

So. Front sway bar links last week to eliminate the thunk-clunk over bumps. Likely-unnecessary rotors and an unexpected front wheel bearing this week to eliminate the front-wheel shimmy. Next week I’ll hopefully address what feels like a dying power steering pump. Combined with the freshly-replaced windshield a few weeks ago, the E39 is feeling like it’s getting the attention a beloved daily driver deserves.

—Rob Siegel

____________________________________

Rob’s latest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books, including Just Needs a Recharge: The Hack Mechanic Guide to Vintage Air Conditioning. Signed copies can be ordered directly from Rob here.

Tags: shimmy wheel bearing