Kind of late to be putting the patient on the table as the cover photo implies, but ah, the things we do for love.

Last week, I talked about the surprising pain-in-the-butt of replacing the Bavaria’s belts, water pump, and fan. This week, with the buyers scheduled to fly in this Wednesday and drive the car home to Alabama, I was in the home stretch and putting the final touches on the car. I stress that the Bavaria has been a very reliable ride (my traveling companion Jose even drove it to The Vintage last year with the car having sat in a warehouse for nearly a year with zero prep), and that I was doing all this not because I thought the car was incapable of driving 1200 miles if I didn’t, but because the buyers are good friends who are paying fair market value for the car, and this level of preparation and care is appropriate. And, yes, I’d feel like a turd if it dies due to something I should’ve addressed.

With the belts replaced, my plan was to put a hundred miles on the car, then re-tension the belts so they’d be less likely to loosen up and start squealing during the new owner’s drive (they are a pain in the patootie to adjust). I popped a cigarette-lighter voltmeter in the socket so I could monitor charging voltage during the drive. As soon as I took off from the house, I saw that the voltage was sitting at 12.6 volts, indicating that the battery wasn’t being charged. I beat it back home and checked the voltage at the battery with a proper multimeter. Yup, no charging. I replaced the car’s voltage regulator with one I’d tested as a good spare, but found that it was putting out nearly 15 volts. I didn’t have another spare regulator, so I put the original one back in, made sure the plug was seated, and was happy though puzzled that the voltage was around 13.5. Whether it was just a loose plug or the regulator was flakey remained to be seen.

So I put my desired hundred miles on the car, driving it from my home in Newton, Massachusetts, out the Mass Pike to where it hits I-84, then turning around. In 75-80 mph traffic, the car behaved flawlessly. The a/c kept me cool, though it wasn’t quite as bone-chilling cold as remembered. This car is the last of several I owned that still were running on R12 and not R134a, and when I rebuilt its a/c, I threw every trick in the book at it, including the Freon charge. It was comfortable, but Freon should get the evaporator so cold that your hands and knees hurt, and I could hear the compressor cycling on and off more than I thought it should.

This was okay, but I remembered better.

When I got back home, having nothing to do with the a/c, I made the mistake of checking the dwell and timing (mistake because it appeared to open up a wormhole that sucked me in). I adjusted the point gap to set the dwell at about 40 degrees, then looked at the timing, which I doubt I’d checked in nearly a decade. This is a car that originally had dual Zenith Strombergs but now has dual Weber 32/36s, is de-smogged, and still has its vacuum advance/retard dual diaphragm on it with the advance side hooked up to the base of the Weber. As I’ve written before, there’s really no simple answer to how to hook up the vacuum advance on a de-smogged car. My pro-friend Paul Wegweiser says he unhooks all the vacuum lines, sets the total advance at nearly 40 degrees, and only connects vacuum advance or retard if the advance at idle is wildly off. Disconnecting the vacuum advance and using my advance timing light, I couldn’t get either the TDC mark or the timing ball to show up in the bell housing window, and I couldn’t figure out why. I tried to twist the distributor slightly, but it wouldn’t budge until I twisted it hard, and then it moved a lot, so I lost the reference of where it had been. I finally got it settled at about 30 degrees of total advance, drove it again, and all still seemed well.

I should’ve left well enough alone, but trying to take Paul’s advice (he’s a pro, I’m not), I moved the total advance closer to 35 degrees, and drove the car again. The car still seemed happy, no pinging on hard acceleration, but when I got back to the garage, I found that the idle was at around 2000 rpm. When I rechecked the timing, the distributor was barely advancing with increasing rpm. It seemed like the advance had gotten stuck. I’ve seen many long-dead vintage cars whose distributors aren’t advancing at all with rpm, but have never had one go from working to not working in one drive. I messaged Paul to get his opinion.

I thought I had a spare 6-cylinder distributor somewhere, tore the garage apart, and found it. I’d bought it many years ago to have as a spare for my E9, which has L-Jetronic injection from an E12 528i and the factory electronic ignition that went along with it, the parts for which are now unobtanium, so I wanted an old-school points-and-condenser dizzy I could throw in the trunk for a road trip. Unfortunately the thing was filthy and the shaft lobes were pretty badly corroded.

Yuck.

In addition, this style of distributor is larger than the one in the Bavaria, with a different cap, rotor, points, and condenser (the condenser mounts on the inside, and the wire comes off the points in the opposite direction to normal, so the wire on standard points doesn’t reach the condenser). But with some cleaning with a little Scotch Brite wheel on a Dremel tool, taking a file to the faces of the points that were in it, and opening old boxes of E9 parts to find a cap and rotor, I managed to make the spare dizzy, well, a spare dizzy. I dropped it in the Bavaria and was about to set the timing.

MUCH better.

Just then, Paul called me. I described the situation, and asked rhetorically “So, it sounds like the advance quit working, right?” Paul said “Yeah… or it could be that, with your high 2000-rpm idle, there just wasn’t a lot of advance left between that and 3500. You weren’t revving it from 800 rpm to 3500, right? That might have looked very different. Time it at 40 degrees total advance, but lower the idle to about 800, and see what the advance range is then.”

Damn. I hadn’t thought of that. Another case of diagnosis being like the Jackson Browne line in Fountain of Sorrow, where he says “What I was seeing wasn’t what was happening at all.”

The Bavaria’s original small-bodied vacuum-advance-and-retard dizzy (left), and the resurrected spare somewhat odd large-bodied vacuum-retard dizzy with the condenser on the inside (right).

In the morning, I pulled the spare dizzy back out and dropped the original one in. It was easy to set the total advance to 40 degrees, but dropping the idle to 800 was surprisingly difficult due some oddities of the dual Weber’s linkage configuration. In order to change it and get the throttle stops resting on the screws so I could back them off, I had to undo some of the things that synchronize the carbs, and I don’t have the adapter needed to sit a Uni-Syn on top of the Webers (I borrowed Paul’s the last time I needed to do that). I was sufficiently rattled by the whole thing that I advised the buyers that, even if I pushed through to a solution, they might want to schedule a “spa day” for the Bavaria at Wegweiser Automotive Services (which is largely on the way during their drive home).

But I got it done, nailed and wailed on the Bavaria to be certain it wasn’t pinging, and was relieved that there there was nothing that screamed “You screwed up the carb synchronization.” I messaged Paul that I had the total advance set at 40 degrees, and a roughly 15-degree advance at an 800-ish rpm idle.

“That’s exactly where it should be,” said Paul. Nice to know that I’m not all hacks and bad judgement.

Still, the “spa day” idea was good insurance. I left it to the buyers and Paul to work out.

One other thing that had been bothering me was the sediment I’d found in the float bowls, filter, and fuel pump. I’d installed a clear fuel filter so I could monitor it, and was indeed seeing a bit of sediment in there, indicating that it was coming from the gas tank (yeah, like it could’ve been coming from anywhere else). I’d intentionally run the tank down low in my test-driving. On Saturday morning I took a clean catch basin, positioned it below the fuel tank’s drain plug (why every single car doesn’t have one of these I haven’t a clue), and began to let the gas drain out. Then I stopped because I realized that I had a little hand-held screen like a cook would use to de-pump lemon juice. I put it underneath the drain and let more fuel out and through it. I figured that, if the bottom of the tank was swimming in sediment, a lot of it would flow out, but I saw very little in the screen, and only a small amount in the catch basin before I began using the screen. I decided that the problem was not acute—that there wasn’t so much sediment that it was likely to clog up the fuel filter during the drive to Alabama.

The last item was the a/c. Not unlike the timing, I hadn’t touched it since I did the major sort-out on the car between its first and second trips to The Vintage in 2014 and 2015. I was hesitant to put a manifold gauge set on it, since it was still using the old-style threaded service fittings that look like tire valves. Unlike the R134a service fittings which snap on and off without losing a puff of refrigerant, the threaded fittings cause a cringe-worthy amount of refrigerant loss while you’re unscrewing them. I played with installing R134a adapters on them, but when I rebuilt the a/c system, I let the fittings on the back of the compressor be the only service fittings on the car, a decision I now regret. There’s not enough space between the two fittings to put adapters on.

I threaded the hoses onto the charging fittings, and turned on the a/c. I could see that, with the car in the shade of my garage and the outside temperature in the low to mid 80s, the high-side pressure was about 150psi, which seemed a bit low. In addition, I could see on the gauges that the compressor was cycling frequently. Compressor cycling can be due to low refrigerant—the pressure switch on the receiver-dryer can cause the system to cycle on and off. I began to shoot a can of Freon into it, then realized that my revived system in this car has no pressure switch on the receiver-dryer. Still, the head pressure did seem low, and the extra Freon brought it up to about 200, which seemed appropriate.

The other thing that compressor cycling can be due to is the temperature probe in the evaporator assembly switching off the compressor to prevent evaporator icing. While you want it to do this, it may be overly conservative. I remembered reading on the E9 forum that the amount of compressor cycling on the original Behr system can be changed by tweaking a small Allen-head adjustment screw on the back of the temperature switch. I found the post on the E9 forum describing the adjustment (it’s here), and very carefully pulled the a/c faceplate out of the console and pulled the temperature switch out the back, but on mine, it wasn’t an Allen-head screw as described; it was a tiny slotted screw.

You can’t see the tiny adjustment screw; it’s above and between the two connectors.

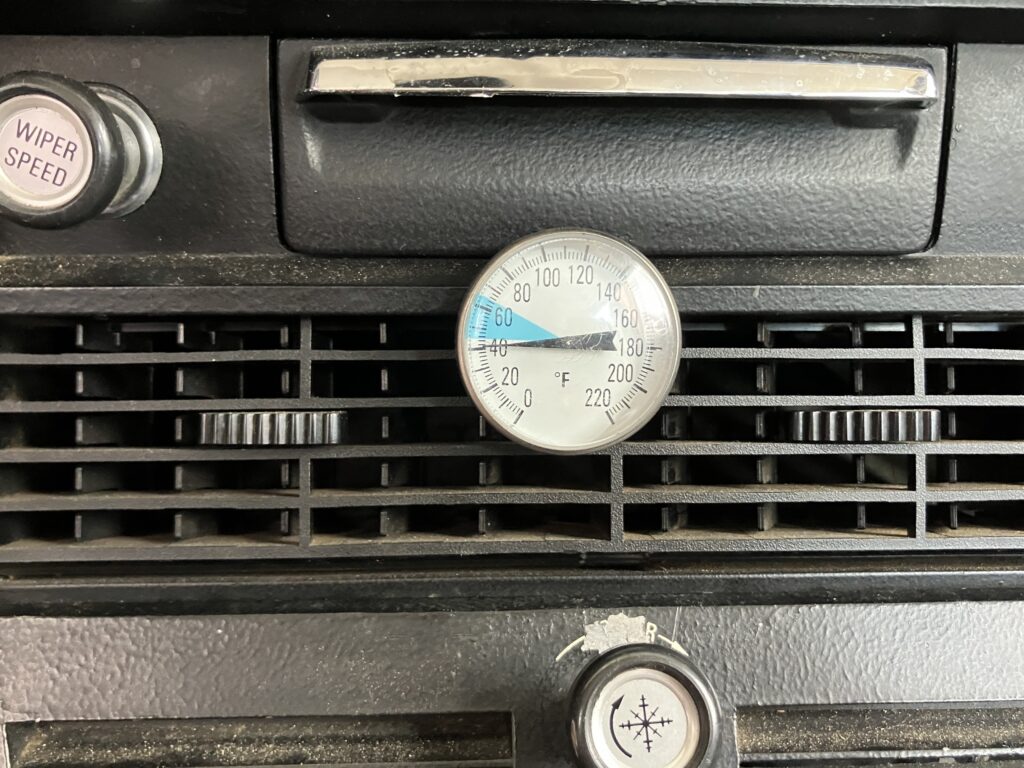

I adjusted it a quarter turn, then another, and it did seem to slightly increase the on-off-on compressor cycle time. Together with the additional Freon, the change resulted in the Bavaria now putting out 40-degree vent temperatures at idle in my garage.

This will make the new owners very happy.

There was really only one more thing on the checklist—put a torque wrench on the lug nuts. After all, think of how I’d feel if a wheel got loose on the owners (hey, it’s happened to me multiple times). So I carefully popped the hubcaps off the original E9 (and optional Bavaria) alloys, and when I got to the left rear and was ready to put the cap back on, I held it in my hand, looked at it, and burst out laughing. Most of you by know probably know the story of Paul “feathering” the Bavaria on its first trip to The Vintage (then called Vintage at the Vineyard) in Winston-Salem in 2014. I thought I’d found all the places he’d hidden feathers. I was wrong. I realized that, even though I apparently solved the odd timing issue and there were no acute carb sync issues, it did make sense for the car to have a “spa day” with Paul. After all, he had “worked on it” before.

There really IS no escape. Except selling the car.

I’ll test the car one more time early this week when above-90-degree temperatures are forecast, but I think I’ve done what’s necessary and appropriate for it and its new owners.

Whew!

—Rob Siegel

____________________________________

Rob’s latest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books, including Just Needs a Recharge: The Hack Mechanic Guide to Vintage Air Conditioning. Signed copies can be ordered directly from Rob here.

Tags: bavaria feathers timing