Last week, I got slippery-sloped and rabbit-holed by the broken bolt on the corner of the FrankenThirty’s upper timing cover when I realized that it’d never be easier for me to address than before I reinstalled the condenser. So I had at it and secured the cover by drilling out the bolt enough to tap it and thread in a small 10-24 bolt that held the cover secure enough that the distributor cap wouldn’t shift around. With that done, I could install the Nissens parallel-flow condenser and the original fan that I wrote about the week before last.

Time to stuff this pair into the FrankenThirty’s nose.

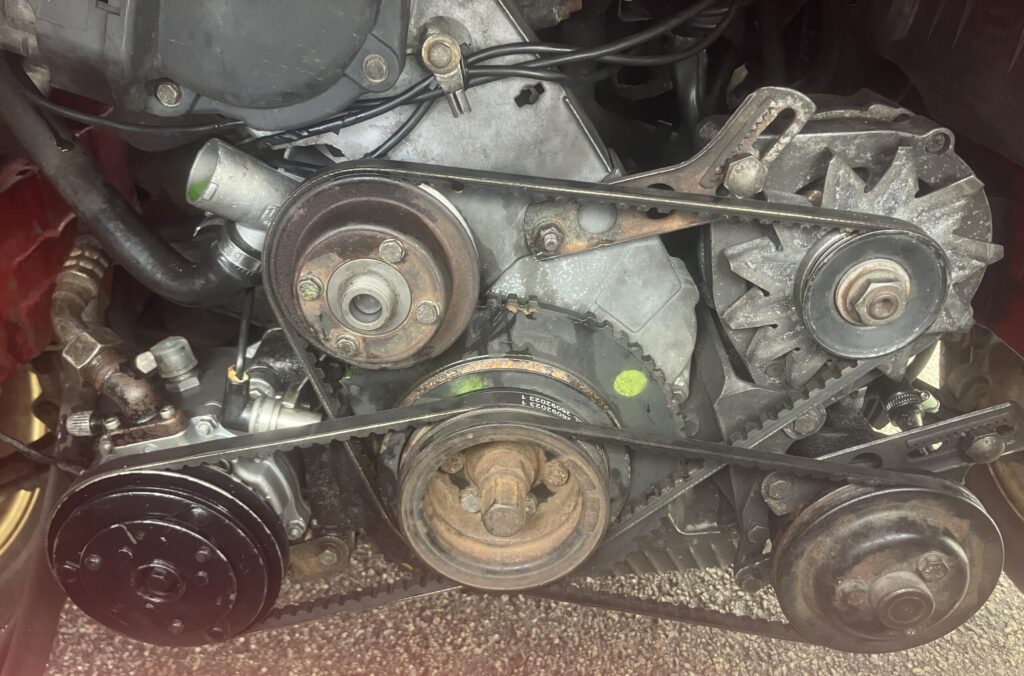

But, as Satch would say, wait a minute, pardner. With the condenser and radiator still out, the clear access to the front of the engine made it much easier to button up the unfinished compressor installation. Unfinished? Yeah, well, for starters, I’d never installed the belt, and in order to do so, the power steering belt had to come off. In doing so, I encountered the issue I’ve seen multiple times in the past on E30s—in order to get belts on and off their pulleys, slackening the adjustment track sometimes isn’t enough, and I’ve had to unbolt the accessory, tip the pulley at an angle, slip the belt on, then re-mount it. (I routinely need to do this on 2002s with retrofitted-on Sanden a/c compressors, but I’m always surprised when I need to do it on a stock E30 compressor and power steering pump.) Also, the toothed-nut-on-toothed-track belt adjustment setup is great when everything is new, but with age, teeth are missing (both yours and the adjuster’s), and it’s not the gee-whiz-I-want-to-install-one-of-these-on-the-2002 improvement that you once thought it was. But I got the system belted.

Snug as a submissive trussed up by a dominatrix. Not that I would know.

And with that, the parallel-flow condenser and finally went in. After weeks of incremental progress, it felt good to do something big and visible, even if it only took 45 seconds.

Nice, right?

The radiator was next. When I bought the FrankenThirty, I found that it had a pre-facelift cooling system, including a radiator that had glaring smush marks (and more), likely from an impact suffered by the donor car for the rebuilt salvage title (it’s a radiator for an automatic). Back in the fall, I found another used pre-facelift radiator, this one with a thicker core and without the ATF cooling ports, for $50. I dug it out of the back of the garage, rinsed it, and installed it. That was soon followed by the hoses, fan and clutch, and coolant.

Better on the left? Right!

Suddenly the FrankenThirty was mobile again. This was good. I don’t like having dead cars in either my garage or my driveway. I could return to the piecemeal a/c rejuvenation I’d been doing since early winter.

And that brings us to a/c hoses. When resurrecting a long-dead a/c system, I say in my book Just Needs a Recharge that if you think you’re going to get out of it without replacing the hoses, you’re fooling yourself. Really, there are only four of them, so if you own a bead-lock fitting crimping tool, you can make them all for about a hundred bucks. The problem, though, is that an E30 isn’t a vintage car like a 2002 where the hoses are, well, hoses—rubber end-to-end. Most of the length of the E30’s a/c plumbing is custom-bent aluminum tubing that hugs close to the curves and corners of the body. Some hoses are hybrid combinations of aluminum and rubber. Just one—the discharge hose from the bottom of the condenser to the input to the receiver-drier—is simple rubber.

Earlier in the winter, I’d done a cursory check of the pressure-tightness of the a/c system and got it to the point where I could pressurize it with nitrogen and not see the gauge move when I watched it, but it would go down overnight. Further, the discharge lines had a non-trivial amount of rust inside, probably originating with the rusty condenser, which was why I replaced it.

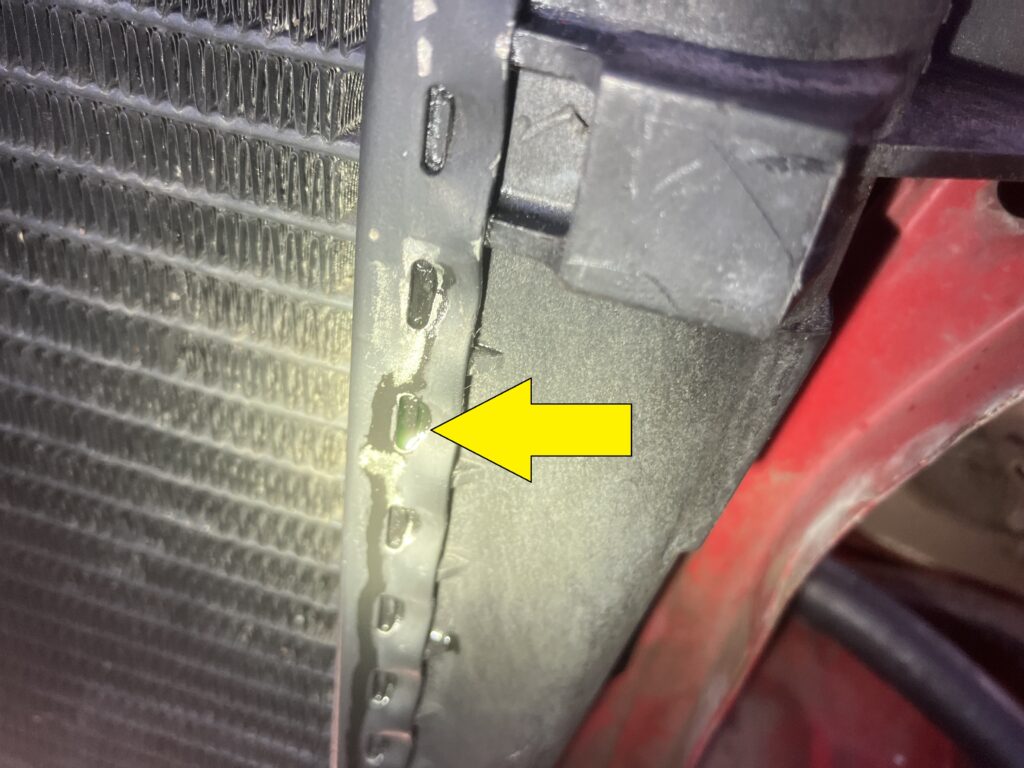

So I took this opportunity to inspect the hoses. I found that the condenser discharge hose had a small gash in it. Whether this was the source of the leak, I didn’t know, but since it was original to the car, was gashed, and was the only all-rubber hose in the system, it would’ve been silly not to fabricate a replacement.

Not good.

I dug through my stash of fittings and found that I needed to order the 45-degree one. $12 and a few days later it arrived, I hauled out the Mastercool Hydra-Krimp (one of my favorite tools in my garage), and fabricated a replacement.

I freaking love being able to do this.

The other hose that was gave me some concern was the discharge line from the compressor to the top of the condenser. This is a half-rubber half-aluminum hose, and unfortunately I could feel that the rubber section had a bulging aneurysm behind the crimped-on fitting. Like the other hose I’d fabricated, this one was clearly original to the car.

Also not good.

I looked at the path this hose took, and felt that, really, it wasn’t so tight that it needed to be hybrid bent-aluminum-and-rubber, and that I could crimp one up myself. I test-fit some 90-degree fittings, didn’t like the way the hose’s path interfered with the other components, decided I needed to order two 45-degree fittings, and then discovered that I could buy the correct form-fit metal-and-rubber hose (Four Seasons 55593) from Rockauto for about $45 shipped. Okay, so that’s as compared with buying two fittings, a few feet of hose, shipping… shrug. Sure. Fine. Rockauto yet again. Click. Buy. Done. I’m hoping I don’t need to replace the metal-and-rubber compressor suction hose, as that one’s a bit more pricey.

I probably could’ve crimped up an all-rubber replacement for this, but for an extra $20, took the easy way out.

But while I was back in waiting mode, I thought I’d take the FrankenThirty for its first spring drive. Or if not that, at least start it to make sure it was alive after reassembly. After all, I did have the cap, rotor, and sensor wiring off the front of the engine. I was relieved that the car started immediately. I let it run so it could suck coolant in, topped it off, let it run on the jack stands for about five minutes, shut it off, crawled under it to check for leaks, and…

What is this dripping coolant from the bottom right corner of the radiator?

My assumption was that it had to be coming from the hose at the top right, but its connection was tight and dry. I pulled off the fan, clutch, and shroud, wiped off all coolant, and watched it run. It was barely noticeable, but sure enough, the drip returned. I took the car for a test-drive to be certain. Careful inspection showed that the leak appears to be coming from the joint where the plastic tank on the right side is crimped to the radiator core.

Damn it!

Read it and, uh, weep.

So, the used $50 radiator I picked up last fall appears to be bad. It’s my understanding that mass-market radiators for pre-facelift E30 cooling systems are no longer made. My choices appear to be to install the one that was in the car when I bought it (smushed, thin core, ports for automatic transmission lines, but doesn’t appear to be leaking), or try my luck with another used one, or spring for one of the $100 Chinese-made ones available on eBay. I’ll likely go for the latter.

But between the a/c hoses and the radiator, this is a fine example of why it’s difficult to shut the spending off on a car. If the goal is to drive it—and I still hope to drive it down to The Vintage in May—you’re an idiot if you do so with a weeping radiator, and my strong preference is to get the a/c up and running, and these things all cost money.

As Bruce Springsteen sang, one step forward, two steps back.

—Rob Siegel

____________________________________

All eight of Rob’s books are available on Amazon. Signed, personally inscribed copies can be ordered directly from Rob here.