While BMW’s newest engineering marvels may not have color changing panels, they are the first Ultimate Driving Machines from BMW’s new division that is dedicated to making revered BMW classics new again.

BMW’s newly announced division, BMW NeueClassic GmbH, will focus on future-engineering BMW classic models with all the safety, functionality, performance and sustainability of today’s BMW products. Now clients can commission the re-creation of a half-dozen classic models from BMW’s long and storied history. Initial models offered include the 1938 328 Roadster, the 507 Series 2, the E30 M3 EVO, the E46 M3 CSL, with more models planned depending on client requests.

Each BMW NeueClassic model embodies the dynamics and styling of the originals, but with the benefit of meeting current safety and emission standards, level 2+ self-driving capabilities, and the latest ID9 iDrive (via a hidden heads-up display) system. Even the sound system has been reimagined with Bowers & Wilkins, making that 80s playlist sound better than ever.

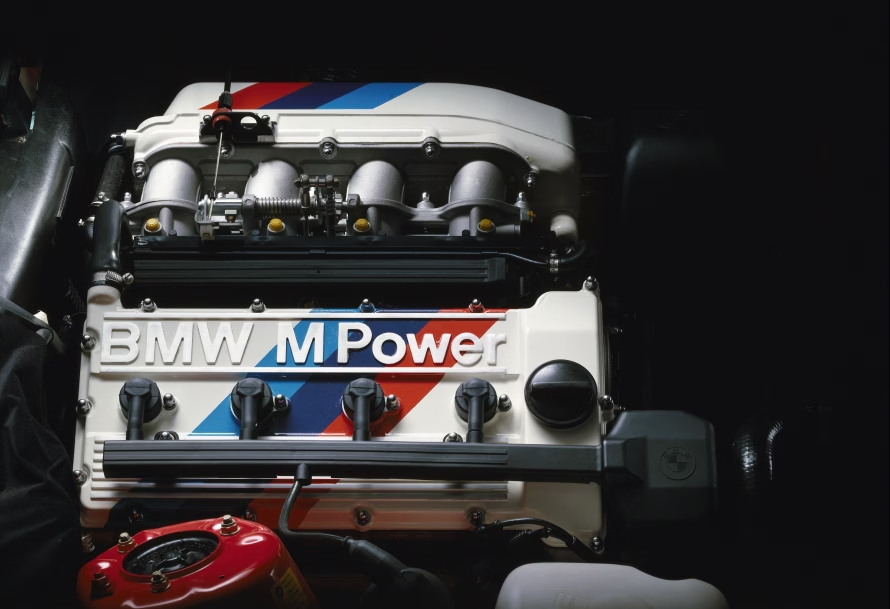

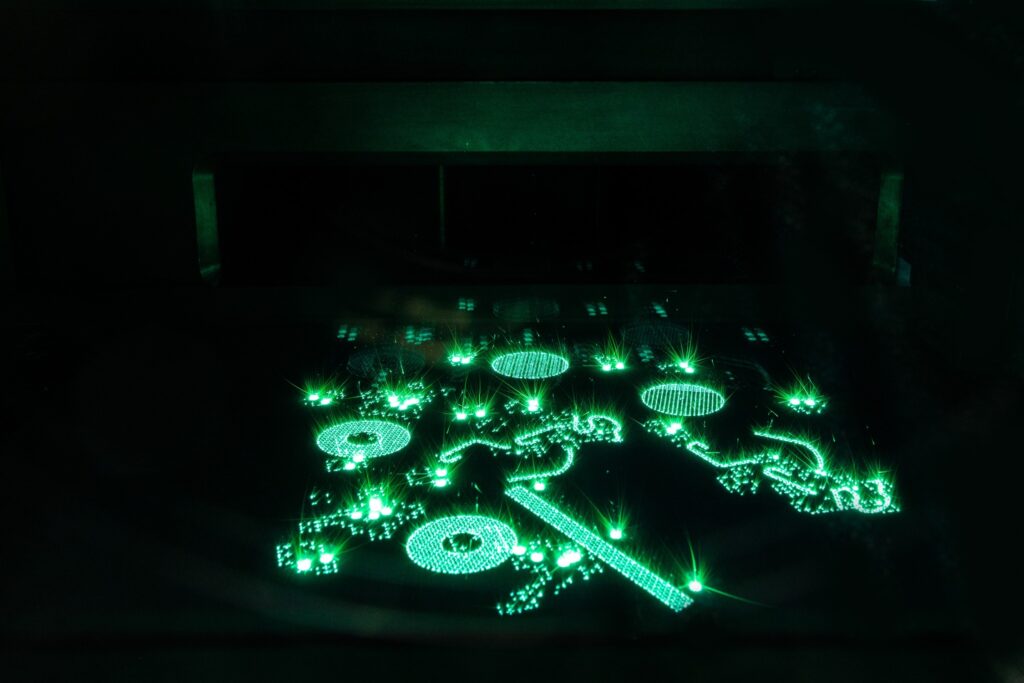

- A variety of technologies went into recreating the BMW NeueClassic E30 M3’s engine block.

- The 2025 BMW NeueClassic E30 M3 EVO was revealed as the first fully-functional showcase of BMW’s skill with advanced manufacturing.

The stunning 2025 BMW NeueClassic E30 M3 EVO shown was built “to showcase the remarkable capabilities and flexibility of BMW’s continued advancement in manufacturing techniques… BMW has long been at the forefront of additive manufacturing. And today we showcase those advancements, as well as celebrating the 50 Years of the 3 Series, by presenting a vision of the future that honors the past. As BMW current design emboldens the future with its Neue Klasse of vehicles, we honor our past with BMW NeueClassic.”

“We have been building toward this for over 30 years,” stated Heinrich Hoffmeister, newly appointed CEO of BMW NeueClassic GmbH. “Enthusiasts no longer have to choose between driving their classic BMW or enjoying all the functionality of a modern BMW. They can now have both in the same car! I love my original E30 M3 but it is not ideal for long drives. With the BMW NeueClassic M3, I have the all the features of a modern BMW, making long drives far more enjoyable. And now, clients can get the classic design, dynamic feel, and ultimate driving experience of a classic BMW—optimized with all the modern safety, technology, and convenience features possible. It is a perfect combination!”

Over 30 Years of Additive Manufacturing

“Since 1991, BMW has worked to develop additive and related manufacturing technologies that work both to create the next generation of Ultimate Driving Machines and better enable us to re-engineer past generations,” Heinrich Hoffmeister stated. “At BMW NeueClassic, we are continuously expanding the use of production aids created through additive manufacturing.”

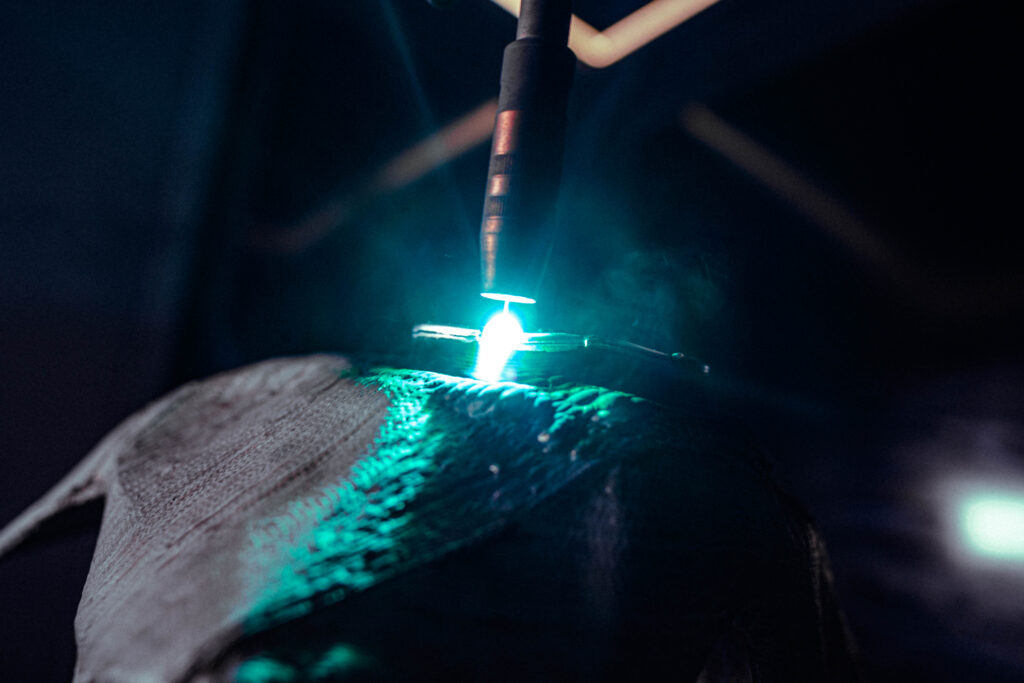

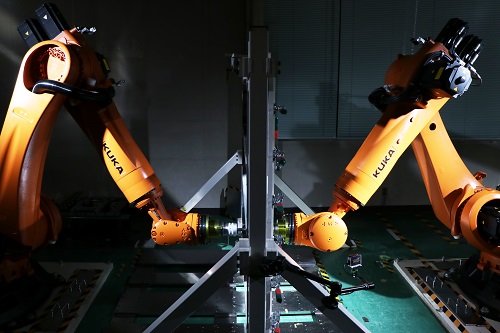

Utilizing advances in precision 3D scanning, additive manufacturing (a.k.a. industrial 3D printing), multi-axis cnc manufacturing, WAAM (wire arc additive manufacturing), and dual-sided dieless forming (a licensed Nissan technology), BMW NeueClassic is demonstrating how these new methods can make new old favorites. The Ultimate Restomod.

And this is nothing new for BMW. As an early 3D printing adopter, BMW has continued to invest heavily in its in-house additive manufacturing capabilities. Back in 2018, the BMW i8 Roadster featured the first metal 3D printed parts on a commercial vehicle, and its MINI Yours Customized campaign used polymer 3D printing to allow customers to add personalized icons and fascia to their cars.

But BMW doesn’t just utilize additive manufacturing, they’ve been one of the main global drivers to develop IDAM: the Industrialization and Digitalization of Additive Manufacturing. The goal of the project — which was led by BMW Group, and funded by the German Federal Ministry of Education and Research (BMBF) — was nothing less than “to revolutionize metal 3D printing in standard production of cars.”

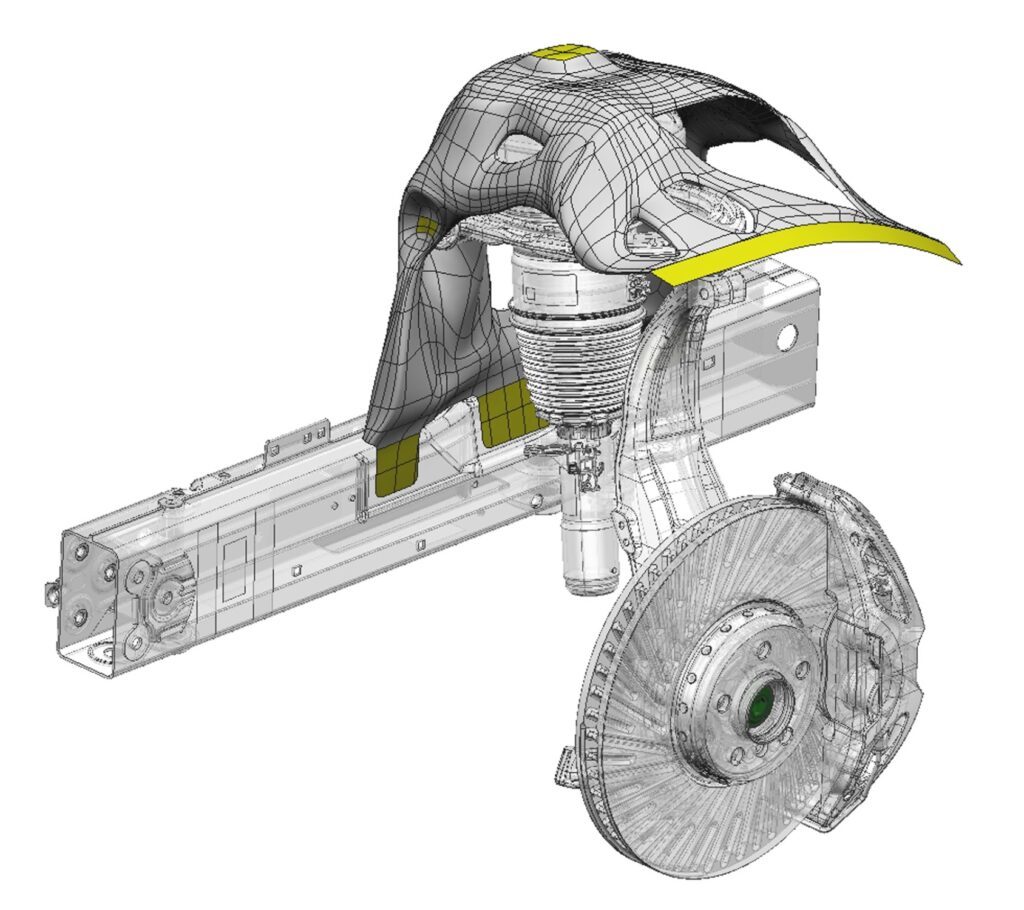

- Super high-resolution scans and 3D modeling allow for recreation or improvement of components.

- WAAM, wire arc additive manufacturing, is essentially a welding technology that builds major components.

- Robotic metal forming technology uses opposing robot arms to precisely scupt sheets of steel, meaning any body part can be perfectly reproduced.

- Laser fusion manufacturing uses high-powered lasers to form parts from metal powder.

In 2019, BMW opened its Additive Manufacturing Center and has pushed to make 3D printed components viable for mass production. Even prior to establishing the campus, BMW had produced more than a million vehicle parts via additive methods at the end of 2018. The BMW Group Additive Manufacturing Center has increased output to over 200,000 components in one year, and is taking steps to both increase the number of vehicles and parts produced.

Now, they’re focusing on scaling things up, both regarding production of parts for classic BMWs as well as the creation of fully-updated, modern versions of popular classics that can be produced through special BMW Individual orders.

Classic Parts and Full Modern Classics On Demand

Modern, super-high resolution scans and computer-assisted design are the keys to crafting the renewed classics. And thanks to new materials and quality control processes, both the parts and the full vehicles will have even better specs. “Using new materials science and techniques, we can significantly reduce weight, increase durability, and extend the service life of many essential components.”

BMW NeueClassic has worked closely with BMW’s Additive Manufacturing Campus and the BMW foundry in Landshut, Germany, utilizing ultra-precise scanning processes, model blueprints, manufacturing records, repair manuals, and testing specifications to create some of the most sophisticated digital models of any previously manufactured cars.

“3D modeling and computer assisted design isn’t just for new vehicles. Once we have every structural brace, connector, harness, and component of the vehicle scanned, we can assemble it digitally. That allows us to not only recreate the individual parts, but to integrate modern technology within the same classic chassis,” Hoffmeister stated. “And now a fully modernized BMW NeueClassic car will enjoy both a classic feel and a modern BMW warranty!”

Pricing and Availability

BMW has not announced any pricing information at this time but, let’s be honest, we know these won’t be cheap.

BMW has dabbled in the area of small production runs with the 3.0 CSL a couple of years back. Those cars reportedly retailed for $750,000, so we are likely in that ball park in this case as well. Currently, a good ground-up restoration will set you back about a half million dollars, so $750,000 to a million seems like a deal for a fully modern classic—especially when you think about the care, craft, experience, and technology that has made these engineering achievements possible. BMW Individual has long created special modifications to existing product lines. Essentially almost every car they produce is a 1-of-1.

But this takes it to another level!

“These BMW NeueClassic commissions will always be very special vehicles and as our technology and manufacturing techniques continue to evolve, the models and options available will continue to grow,” said Hoffmeister.

You can visit the BMW NeueClassic website to see what’s possible. But not quite yet. As this story is being posted on April 1. And we hope you enjoyed it.

Tags: 3d printing additive manufacturing April 1 classics e30 M3