Last week I took the first steps to resurrect the a/c in the FrankenThirty 1988 325is. Its wing-cell compressor turned freely but had no belt on it, and due to the car’s salvage title history, it makes me wonder whether the a/c was ever even fully reconnected and recharged after the car was rebuilt in 1992 in the odd way it was with the pre-facelift nose and the non-original eta engine.

Let me take a step back. As you may know, in 2018, I wrote Just Needs a Recharge: The Hack Mechanic Guide to Vintage Air Conditioning, the only book I’m aware of that details the steps necessary to resurrect a long-dormant system that initially had R12 or to retrofit a/c into a vintage car. The point is that even though I’m not a pro, I’ve done this quite a few times before, and I like to think that I generally know what I’m doing. In the book, I say that if you’re reviving a dead-for-decades system, you’re kidding yourself if you think you’re not going to have to replace every component under the hood—the compressor, condenser, fan, every hose, and of course the receiver-drier which you replace whenever the system is opened up to atmospheric humidity. And if you convert from R12 to R134a, you’re wise to replace the old serpentine condenser in the nose with a modern parallel-flow condenser to compensate for the fact that R134a doesn’t cool as well as R12. Oh, and you need to remove the evaporator core, flush out any old oil and contaminants, and replace the expansion valve. Doing this on a vintage BMW, if you don’t need to buy an evaporator assembly, has usually cost me about five or six hundred bucks (that’s buying what’s generally Chinese-made parts from whoever has the best price and installing them myself). If you skip any of those steps, you dramatically lower the probability that when you charge the system up, it’ll be leak-free and will blow cold.

But just because I say that doesn’t mean I want to do all that on this car (shocking, I know). Even though the E30 is far closer age-wise to being a vintage car, like a 2002, than a modern one, and even though its a/c system was originally charged with R12, a/c-wise it’s more like a modern car than a vintage one in three crucial ways. The first is that the heater and evaporator cores are inside the same box, like a modern climate-control system that can blend warm and cold air. I would normally regard this as a negative due to the climate control boxes often needing the dash to be removed to access the innards, but that brings us to the second issue, which is that the E30’s evaporator core can be slid out of the heater box without removing and disassembling the box like you have to do in a 2002, E9, Bavaria, E12, E24, or E28. That’s a huge positive. The third is that many of the a/c hoses aren’t hoses at all—they’re either aluminum pipes or a blend of aluminum and a crimped-on rubber section. The thinner pre-fit aluminum allows them to run closer to the body and make tighter bends than their rubber-hose counterparts. From a resurrection standpoint, this isn’t really a positive because it means that when doing things like replacing the original compressor with a Sanden or one of its Chinese-made clones or replacing the original serpentine condenser with a modern generic parallel-flow condenser, dealing with the hoses is more involved than simply buying six feet of the three main sizes of rubber a/c hose and a bunch of crimp-on fittings and making them yourself. It also means that if one of these hybrid metal-rubber hoses is leaking, you need to source a replacement instead of just cutting and crimping one up yourself.

Note how the hose entering the receiver-drier on the left isn’t a hose at all, but an aluminum pipe.

Here’s another aluminum a/c pipe coming up from the compressor, around the shock tower, and running tight up against the right inner fender.

If you google “Rob Siegel BMW CCA E30 air conditioning,” you’ll find a series of articles where I faced a nearly identical a/c revival situation on a nearly identical car ten years ago. The ’87 325is I owned back then had a seized compressor, and when I removed it, I found some amount of black particulate matter in the fittings. Fortunately, there’s a big difference between some peppery-looking remnants of hardened black o-rings as opposed to “black death,” which is associated with the Teflon seals in the compressor of mostly Ford products forming a black slurry that gets baked onto the inside of the tubing. ]I sourced a used compressor on Craigslist, drained and refilled it with oil a few times until I was convinced it was clean inside, filled the compressor with Ester oil, which works with both R12 and R134a, pulled the evaporator core out of the heater box, flushed and reinstalled it, flushed every hose and the condenser in the nose, leak-tested the system, and charged it with good old-fashioned R12. It worked perfectly. I don’t really recommend this, as charging with R12 creates a car that almost no shop will work on anymore (well, at least not in the northeast), but it was the quickest, easiest, least-expensive path to getting a cold car, and I’m not above doing it again. And to be clear, there’s nothing illegal about using R12. It’s illegal to discharge any refrigerant into the atmosphere, but my deal with myself is that as long as I leak-test a system before I recharge it and deem it to be leak-free, I can charge it with R12 with a clear conscience.

Fortunately, I have way more to go on than my own experience ten years ago—R3VLimited (the E30 brain trust) has a 47-page “Detailed E30 R-134a Conversion DIY” thread.

But back to the compressor. Last week, I yanked it out of the car. The first task was to drain it of oil and inspect what flowed out. I caught it in a small plastic container with a paper towel in it and could see that the oil was full of small black shavings. They’re likely from the seals in the compressor itself, but I suppose it’s remotely possible that they could’ve originated elsewhere and been transported there in the oil.

Hmmm. Not good.

In addition, the mesh screen on the inlet side of the compressor had a fair amount of matter, some of which looked like rusty metal.

Also, not good.

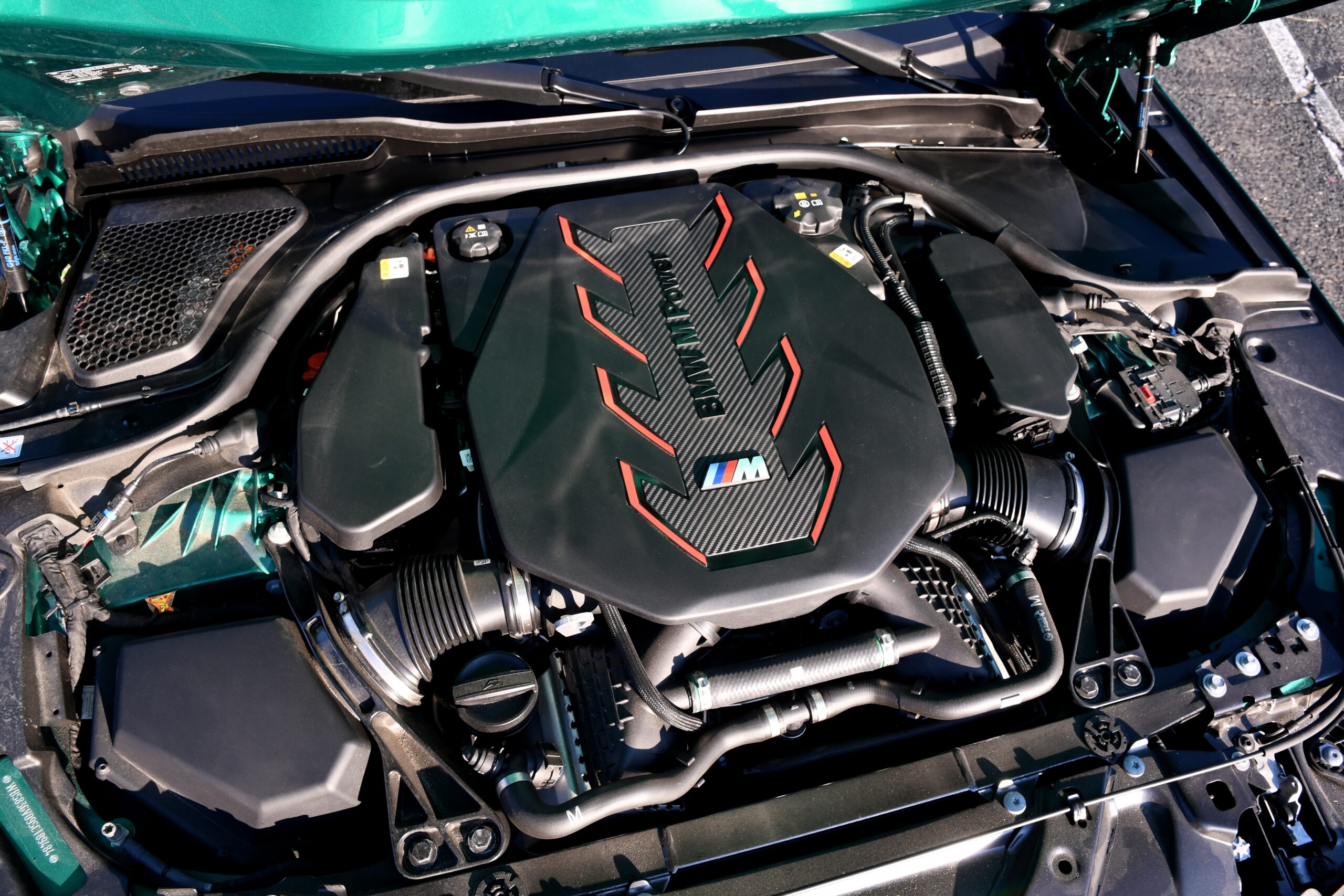

I was unable to pull the screen out of the inlet to clean it, but the inlet port bolts onto the top of the compressor. I first washed and scrubbed the outside of the compressor in my parts washer (see cover photo), then unbolted the inlet port, gently removed the sprung check valve behind it, and blew out the screen from the back.

You can see the black o-ring that seals the bolt-on inlet port up near the flange.

You can probably tell I’m nearing the point where, if someone else said they found these things in their compressor, I’d say they’re delusional in thinking it can be reused. My flinty New England Hack Mechanic sensibilities want me to give the no-or-low-cost option a bit of rope to hang itself. I found a seal kit for the compressor on eBay for $17. I think I’ll pull it apart, see what it looks like inside, re-seal it, remove the receiver drier, see what its ports and hose fittings look like, reinstall the compressor, and do a pressure test. Hey, it’s winter. I need to keep busy.

But yeah… I need to keep my eyes open for a used, known-good wing-cell compressor.

—Rob Siegel

____________________________________

All eight of Rob’s books are available on Amazon. Signed, personally inscribed copies can be ordered directly from Rob here.