If you’ve ever had to remove the heater box in a 2002 to replace the blower fan, leaky heater core, or—heaven forbid—de-mouse it, you’ve had to deal with the Bowden cables. They’re the stiff cables that connect the dashboard sliders to the heater valve and the flaps in the heater box. The good news is that the cables themselves almost never fail. Your main interaction with them is detaching the sliders from the dash (which you do by removing the faceplate covering them, then unscrewing them), photographing things from the underside, documenting what goes over and under what so you know how to reinstall them without kinking them.

I mention all this not because I was tangling with them in one of the 2002s but because I just finished de-mousing the heater box in the recently purchased 1969 Lotus Elan, during which I learned more about Bowden cables than I ever wanted to.

First things first, the name is wrong. For decades, I’ve called them “Bowden cables” because that’s what they’re called in the 2002 world, and that’s what you search for on bmw2002faq.com if you want information. However, according to Wikipedia, a Bowden cable is any control cable that runs in a housing. In contrast, the ones in the 2002 and my Lotus have two specific attributes worth understanding.

Some of you know that before I was a car guy, I was a bicycle guy, and I owe much of my Hack Mechanic gestalt to having curb-scavenged or dumpster-dived bikes, taken them apart, and rebuilt them in my pre-automotive youth. The cables on a bicycle that control the brakes and derailleurs (the components that change the gears) are made from thin, twisted strands of metal that run inside housings. This makes the cables very flexible, which allows them to be connected to the handbrake levers on the handlebars and to function when you turn. But it also means that the cables are designed to pull, not to push. You’re usually unaware of this limitation unless you’ve worked on a bike and see that there are springs in the brake calipers and the derailleurs. When you squeeze the handbrake lever, it pulls the cable through its housing, which pulls the two halves of the calipers together and squeezes the shoes against the rim. But when you let go of the lever, it simply springs back because a spring on the caliper makes separation its natural state, likewise on the derailleurs. They’re sprung, so their relaxed position is in the smaller gears. When you shift to a bigger (lower) gear on the rear wheel or a bigger (higher) gear on the crankset, the cable on the shift lever pulls against the spring. On old-school ten-speed bikes, you could feel this up versus down-shift difference. It’s less obvious on newer bikes because the shifters themselves may be counter-sprung.

All that braking and shifting on a bike only works because the fine-stranded cables move things at the other end that are returned to their resting position by springs. And yes, that’s a Getrag 245 on the left. And no, you can’t have it.

But I digress. What makes the ventilation control cables in a 2002 and other cars different is that they’re push-pull control cables. These types of cables use a single, stiff, thick metal strand instead of a multi-stranded one. The tradeoff is that they pull and push but are not as flexible as a multi-stranded cable. Push-pull control cables like these are used in just about any car that doesn’t have a climate control system (one where you set a target temperature, and the system energizes actuators to move flaps that open and close vent doors). Having trouble-shot my 2008 Nissan Armada and found that I have no hot air out the footwells or the defrost because both of these actuators have failed, I can tell you that I prefer simple cable-actuated systems. They’re also used in various small gas engine products like lawnmowers and snowblowers in the form of throttle, choke, and flap cables.

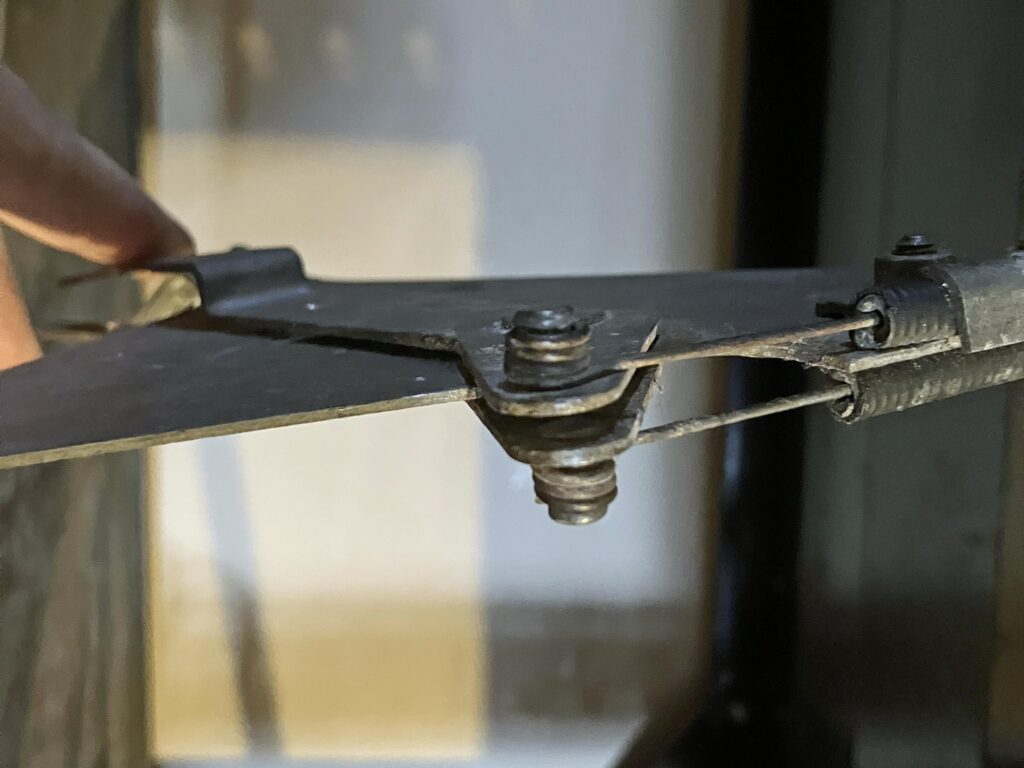

But a behind-the-scenes part of push-pull control cables is how they fasten at the ends. Bicycle or derailleur cables almost always have a small cylindrical piece of metal soldered to one end, and the other end either clamped or passing through a barrel-shaped ferrule with a hole in the middle and a screw or bolt through the top. But because push-pull control cables have to push something at the far end, and because both the near and far end usually move in an arc, the end must be able to pivot. Or rather, the thing being moved must pivot around the cable’s end.

A common adjustable pinch-type barrel ferrule on one end of a push-pull control cable.

For this reason, the ends of some push-pull control cables are coiled in a small loop that slides over a post. You usually can’t see it, but the post has a bulge near the top. The coiled loops act like a spring, expanding slightly when you push it over the bulge, snapping into place, and then being free to move.

So what I’d been calling a “Bowden cable” for decades is more accurately called a “push-pull control cable with loop end,” which doesn’t sound nearly as cool-jargony as “Bowden cable.”

In a 2002, behind these…

…are these loop-end push-pull control cables.

I learned all this because while rebuilding the Elan’s heater box, I found that the heater flap wasn’t working correctly. I examined the cables and found that while the one on the air distribution flap was a proper loop-end control cable that looked just like the ones on a 2002, the one on the heater flap was a stiff strand of wire that had been twisted into something approximating a loop and coerced into service.

This control cable had a proper multi-coil loop end.

This one was else’s hack job.

Since I already had the heater box out, I sought a replacement for the cable. I first thought I could rob a for-parts 2002 heater box I have in the basement, but found that its control cables weren’t long enough for the Lotus. After searching online for “push-pull control cable loop end,” I found that MEI / Red Dot makes a variety available at PartDeal, TruckAir, and eBay. I couldn’t find a spec on the diameter of the wire loop, but the cable was only about $30 shipped, so I bought one that was long enough. The loop end appears to be the same size as in the 2002 and the Lotus, about 0.2 inches. I cut it to length and installed it.

Kluged and proper loop-end control cables.

Below is a photo of the end that moves the heater flap. I’ve zoomed in a lot so you can see the bulge in the top of the post over which the springy loop snaps.

See the bulge near the top of the little post?

If you look closely at the photo above, you can also see a crack forming at the base of the lever. I didn’t know this when I took the picture, but I wish I had. Once the box was installed and I began working the sliders, the lever broke off.

This was not my calmest hour.

At least, for educational purposes, you can now see the bulge in the top of the post really well.

It broke because of an unlikely combination of events. The little arm is clearly made from pot metal, which is never the strongest material. It’s possible that my snapping the loop over the bulge on the post may have caused the crack. Or it might have simply weakened after 55 years of use. While installing the box, there was an error on my part that caused the other end of the shaft that this lever moves to bind up, so my testing the slider was applying torque to the shaft.

Fortunately, I was able to fix things with a visit to a well-stocked hardware store and some good old-fashioned Hack Mechanic ingenuity. It turns out that the little brackets used in adjustable kitchen cabinet shelves have a 5-mm post, which is remarkably close to the size of the post that the loop end of the wire goes on. I combined one of those with a wire-loop clamp, made some adjustments, and got it to work as a replacement heater-flap lever.

Saved by $2.10 worth of hardware.

I doubt anything like this will happen to you—I’ve never had to replace a control cable in a 2002. But if for some reason you ever need to remove or replace the not-technically-a-Bowden-cable in a 2002 and find that it won’t easily slide off the little post on the vent slider levers, or if you wonder why there’s not a circlip on the top of the post securing the end of the cable, you’re not imagining things. It’s surprisingly hard to get the tight little coil of stiff wire over that little bulge. And remember that if you go searching for a “Bowden cable” when what you really need is a “push-pull control cable with loop end,” you’re not likely to find what you need.

And, if you’re futzing with it on a Lotus, don’t force it.

—Rob Siegel

____________________________________

All eight of Rob’s books are available here on Amazon. Signed personally-inscribed copies can be ordered directly from Rob here.