After the elation of buying the essentially rust-free running 1988 325is, followed by the crushing disappointment of finding that it it’s a Franken-car with an eta engine, I still needed to carry through with the basics of making it something that I can either live with or sell. The owner said that the timing belt had last been changed when he bought the car in 2001, so I’d ordered a timing belt kit from FCP Euro (belt, tensioner, and water pump), along with a few things like a new intake boot to replace the one that was split in several places, the three main cooling hoses, and of course new filters and plugs. Then I tore the front of the engine apart even before I knew of the car’s sullied lineage. So task one was simply to put it back together, even though much of the wind had already gone out of my sails.

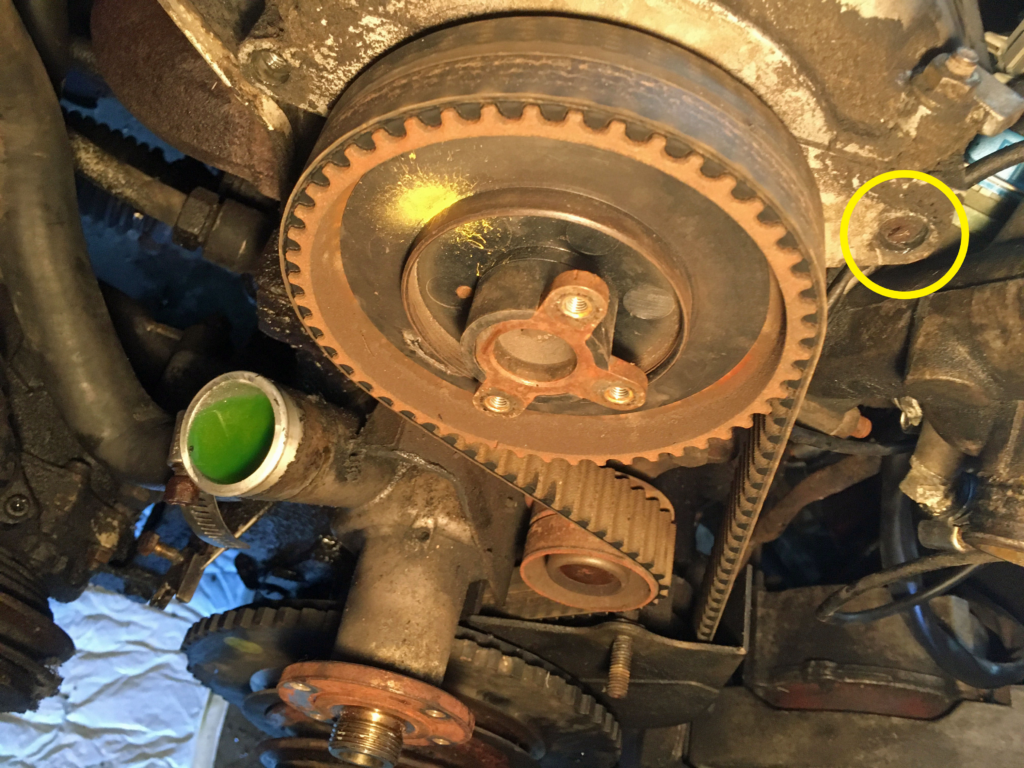

It had been nearly ten years since I last did an E30 timing belt. I’d forgotten what a persnickety job it is. Because this car has the pre-facelift cooling system (whether it’s supposed to is another matter), at least it doesn’t have the crossover pipe sitting in front of the timing cover. It all came apart easily. In fact, a little too easily—the bolt on the left side of the upper cover was missing. When I pulled the cover off, I saw that the bolt had snapped off in the hole. Once I saw it, I realized that the bracket to lift the engine with a hoist was missing. If the car wasn’t so burdened with issues, I might have tried the weld-a-tang-onto-the-bolt trick or performed the full-on drill-out-the-bolt assault.

Compared with all the car’s other issues, the snapped-off upper cover bolt is a small bump in the road. Except…

I initially thought that, on an M20 engine, the upper cover is really just a dust cover. I mean, it doesn’t create an oil seal like it does on every BMW engine with a timing chain I’ve ever worked on. But on closer examination, the upper cover provides the mechanical alignment for the distributor cap to sit in, and a close examination of the cap shows that the rotor had caused two little grooves in it, likely due to the misalignment of the cover. Nonetheless, I added the the snapped-off bolt to the lengthening list of things I’m leaving alone for now.

Those little grooves below the two contacts at the top of the image are more significant than I’d like them to be.

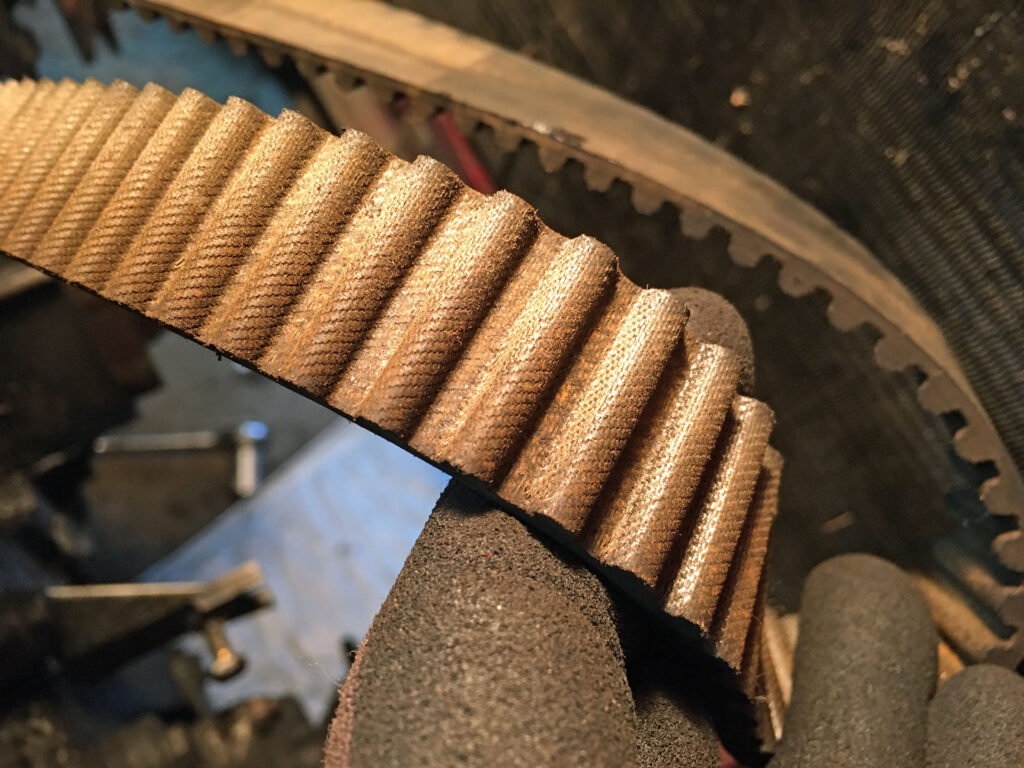

Although no one in their right mind would do anything other than immediately replace a 23-year-old timing belt and the while-you’re-in-there water pump, the belt didn’t appear cracked or dry-rotted. So the idea that I’d put the car at risk even starting it and moving it into the garage was overblown. Similarly with the water pump; it had a little bit of shaft-bearing play, but nothing alarming. The fact that I’d taken a running driving car and immobilized it before finding out that it wasn’t at all what I thought it was was weighing on me. It needed to be put back together in a cost-effective fashion while also not being so stingy with spending that I was either likely making work for myself later or putting the car at risk.

Not bad, but replacing it was still clearly the correct choice.

When I needed to pull the bottom of the timing belt off the crankshaft, I’d forgotten the bit about needing to unbolt the pulley from the crank hub in order to get enough clearance to remove one of the 10mm bolts holding on the lower part of the cover. Fortunately the pulley came off without any dent-creating persuasion.

A few days later, a big box arrived from FCP. When I opened it and opened up the not-exactly Christmas presents, I realized that there was a problem. The Graf water pump that came with the timing belt kit I’d ordered was the correct single-inlet pump for an ’88 E30, but because my Franken-car had the pre-facelift cooling system, it had the dual inlet pump. My mistake. I ordered the older-style dual-inlet Graf pump from FCP, as well as a few other items that had made their needs known.

Post-facelift single-inlet pump on left, older-style dual-inlet on right.

While I waited for water pump #2 to arrive, I pulled off the camshaft sprocket to see if it was the older failure-prone style or the stronger updated style, and was pleased to see that it was the latter. While it was off, I replaced the camshaft seal and o-ring. To my surprise, two cam seals were part of the FCP timing belt kit, but the o-ring was not. I called them hoping the water pump hadn’t shipped and they could add the $2.99 seal to the order. Unfortunately, the pump was already in the shipping queue, but they were kind enough to credit my account for the $6.99 single-item shipping for the o-ring.

New cam seal and o-ring ready to go back on.

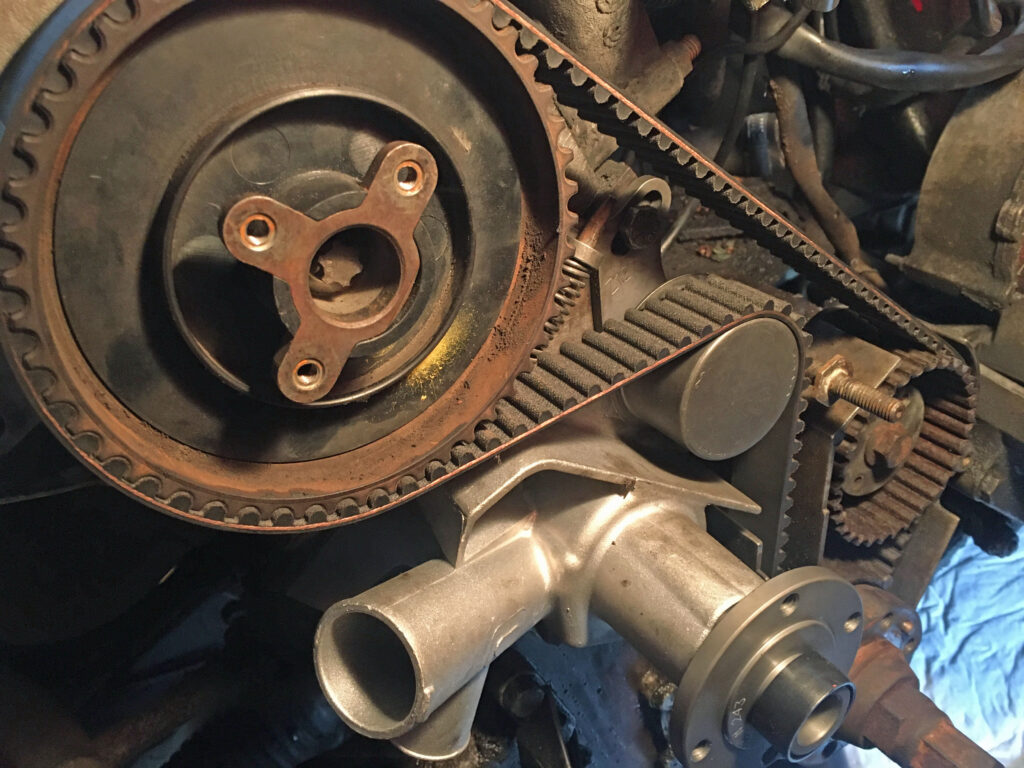

I installed the new Graf pump, then started in on the timing belt installation. It went slowly, not because of any questions of alignment of the crank and cam to their fiducials, but because I’d forgotten about the weirdness that the belt “tensioner” doesn’t supply any tension in the way that a serpentine belt tensioner does. It’s really more like an adjustable idler pully. The initial tension is supplied by a spring that slides over a metal rod, one end of which sits in a little recess in the side of the timing belt, the other in a hole in the tensioner, the whole thing looking like it was an engineering afterthought. My 66-year-old neurons apparently fire well enough to remember the trick of putting a ratchet and socket on the belt’s actual toothed idler pulley (the one beneath the tensioner that spins the oil pump) and using it to gently pull the slack out of the part of the belt between it and the crankshaft to allow you to get the ribs into the correct cogged slots on the camshaft gear to make the marks line up. Once it was together, I smiled.

Yes. But wait. No.

Then, before I began installing the timing belt covers, without even thinking, I reflexively grabbed the hub of the newly-installed water pump and gave it a shake. And it was a good thing I did, because the damned thing had more play in it than the likely-original water pump I’d removed. I’d had this happen one other time with a Graf pump. I ordered a Hepu pump from FCP, set up a return for Graf pump #2, then pulled everything back apart and waited five days for UPS to deliver pump #3. This time, I had the presence of mind to check the bearing play before I installed it in the car. And having just installed and removed the timing belt, this time its reinstallation took minutes.

Second time’s the charm.

Normally, if I was recommissioning a car like this that’s clearly had no real maintenance in decades with the intent of driving it to The Vintage, I’d renew just about every item in the cooling system, certainly including the radiator, expansion tank, fan, and viscous clutch. But as I said above, the fact that the car isn’t what I thought it was is making me be vigilant on spending. The pre-facelift radiator has substantial smush marks from where the cooling fan clearly has been rubbing against it for some time, but rather than replace it (it’s NLA; I’d need to source a used one), I’m just going to put things back together and evaluate the situation. Even the thermostat is giving me pause. One came with the timing belt kit, but while trying to loosen the long 10mm bolts holding the thermostat housing to the head, the “DANGER UNUSUALLY HIGH TORQUE FOR SOMETHING SO SMALL” sensor in my right arm went off. If, when I begin driving the car, I find that the thermostat is stuck closed, I may give it another go, but for now I’m leaving it be.

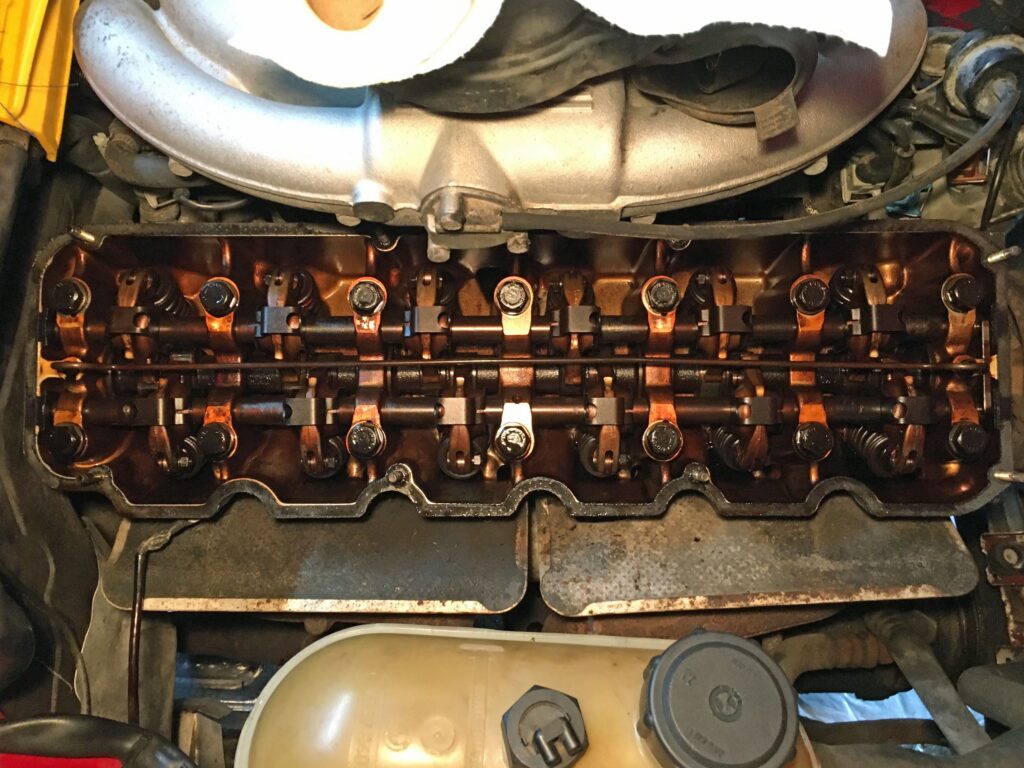

Similarly with the head bolts. I pulled off the valve cover last week, initially to adjust the valves, and then to inspect the valve train to determine if it was the “i” or the “e” head (sadly, “e”). When I posted this photo to my Facebook page, half a dozen friends noted that I have the old style of head bolts which are in danger of snapping and should be changed to the updated Torx style. While they’re reasonably priced ($27 for Reinz, $54 for Genuine BMW, whatever that means these days for E30 parts), it’s something that doesn’t need to be done right now and that there’s little barrier of entry to doing later.

Clearly no one had been in here in decades.

So, cooling system reassembly, J-B Welding the small crack in the oil pan, and replacing the filters should get me a car that can start, move, and drive. Except that the cowl and heater box are torn apart while I try to de-mouse them. I’ll leave that story for next week.

—Rob Siegel

____________________________________

Rob’s newest book, The Best of The Hack Mechanic, is available here on Amazon, as are his seven other books. Signed copies can be ordered directly from Rob here.

Tags: budget Frankencar updating parts