The expansion of BMW Brilliance Plant Dadong, part of the BMW Brilliance Automotive presence in Shenyang, China, has been completed on schedule despite the ongoing challenges of the last three years, and is ready to begin production of the China-exclusive long-wheelbase X5. Announced last month, the extended version of the X5 measures 5.1 inches longer than the conventional G05 X5, has a larger second row for seating, and is offered in xDrive30Li and xDrive40Li trim, with four- or six-cylinder engines respectively. Up until the expansion of BMW Brilliance Plant Dadong, the overwhelming majority of X5 SAVs have been produced at BMW Group Plant Spartanburg in South Carolina, BMW Group’s largest single production facility. Because of a tariff on imported vehicles, adding X5 production capacity in China has previously been summarized as having no affect on X5 production in the U.S., which supplies global markets with the model.

In addition to the X5, BMW Brilliance Plant Dadong also produces the 5 Series and the X3 for the Chinese market, along with the all-electric iX3 for the global market with the exception of the U.S. The plant in Dadong is not the only BMW Brilliance production facility in Shenyang. BMW Brilliance Plant Tiexi is located on the other side of the city, and produces the China-exclusive 1 Series sedan and the 3 Series, along with the X1 and X2. BMW now owns 75% of the BMW Brilliance Automotive joint venture in China, and together, the Dadong and Tiexi plants produced more than 700,000 vehicles in 2021, accounting for nearly one third of global output. This summer, BMW Brilliance Plant Lydia, where the new all-electric long-wheelbase 3 Series will be produced solely for the Chinese market, will also commence operations

“Plant Dadong proves the strength of our team,” said Milan Nedeljković, BMW AG board member for production. “Despite the challenges of the last three years, this complex construction project was completed fully on schedule. Our Chinese production sites are highly significant for the BMW Group. Last year almost one in every three BMW Group vehicles delivered around the world was manufactured in Shenyang.”

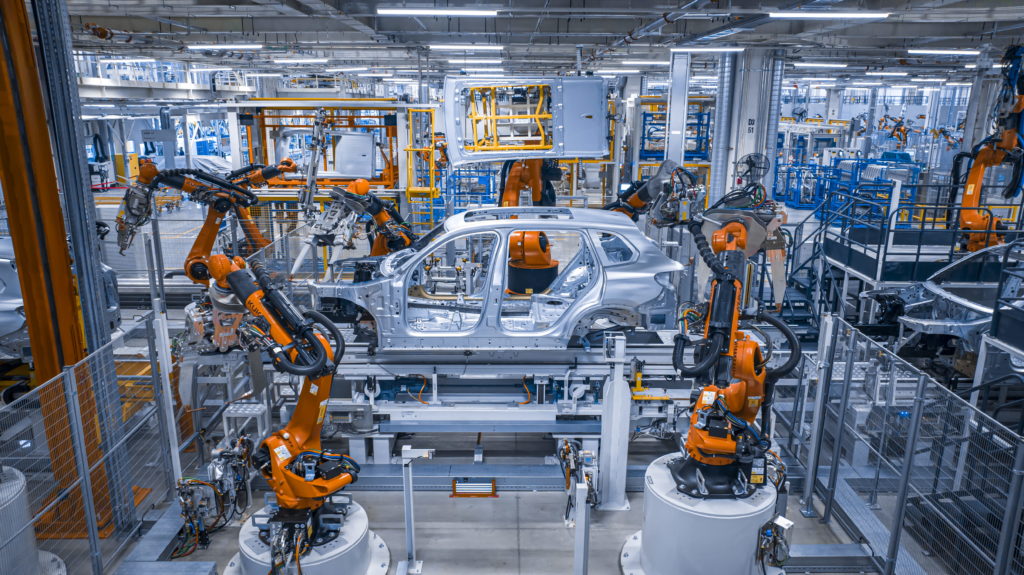

As one of the latest projects completed within the global decentralized BMW production network, the expansion of BMW Brilliance Plant Dadong represented an opportunity to champion the principles of the BMW iFactory, which means the plant is lean, green, and digital. The facility is also described as a pioneer of what’s referred to as industry 4.0, and offers full production flexibility in regard to drivetrain choices. BMW Brilliance Plant Dadong can produce vehicles with internal combustion, fully-electric, or plug-in hybrid electric drivetrains, and can allow BMW to react in near real-time to market trends and customer demands. The plant now has a footprint of 9,795,158 square-feet, and is home to the largest Kuka Titan robot, which can lift nearly 2,900 pounds. The plant also features two independent assembly lines and completed vehicles are transported away by rail on one of nine lines connected to the facility.

“In China, we are determined to lead from the forefront: green, lean, digital! Driven by technology and innovation we create more value for our customers,” said Franz Decker, president and CEO of BMW Brilliance. “Building on 100 years of BMW manufacturing experience we build-up one of China’s most advanced and intelligent production sites here in Shenyang. Plant Dadong extension will once again set benchmarks on sustainability, productivity, digitalization and agility.”

In terms of sustainability, BMW Brilliance Plant Dadong has a number of things going for it. The onsite press shop can perform clean separation of aluminum and steel, while the paint shop operates with zero fresh water input. The plant’s solar array was also significantly expanded, and its 1,926,740 square-feet of panels are forecasted to produce more than 21 megawatt-hours of energy this year. In total, BMW Brilliance Automotive has 3,121,534 square-feet of solar panels the Liaoning province, and more charging stations have been added for employees at the plant in the Dadong district.—Alex Tock

[Photos courtesy BMW AG.]