BMW is joining the likes of big automakers Volkswagen and Toyota in pursuit of next-generation solid-state batteries for hybrid and electric vehicles. The announcement from BMW arrives on the heels of similar intentions being made public at Toyota and Volkswagen, the world’s largest and second-largest automakers by volume in 2020 respectively.

According to its release, BMW plans to be implementing the use of solid-state batteries in series production by the end of the decade, while a demonstration vehicle, or concept of sorts, will likely be unveiled well before 2025. Solid-state batteries boast numerous advantages over the conventional lithium-ion batteries which currently power electric and hybrid-electric vehicles, most of which are centered around their elimination of the requirement for an electrolyte fluid between the anode and cathode, which improves safety by reducing fire risk and shortening charging time.

BMW’s efforts to develop and produce solid-state automotive batteries at industrial scale are consistent with the company’s intentions to create sustainable battery cells using materials sourced in the least impactful way possible.

“The greenest electric car in the world will be a BMW—sustainable from the initial idea to recycling after its use phase. We are developing the battery cell of the future: it will be powerful, safe, cost-effective, and recyclable—from material selection to recyclability after the use in the vehicle. All of this will be created in a European value chain,” explained Frank Weber, the BMW board member responsible for overseeing development.

The forthcoming solid-state lithium-ion battery technology will be a core technological pillar of BMW’s upcoming EV platform, Neue Klasse. Focused on technology, digitization, electrification, and being “circular” in terms of the supply and value chain, Neue Klasse will heavily rely on concepts like solid-state batteries to make its case.

“With the Neue Klasse, we will make a big leap in technology in electric drive,” said Oliver Zipse, chairman of the Board of Management of BMW AG, in Munich on Monday. “We want to significantly increase the energy density of the cells and reduce the costs of material use and production at the same time. We will also significantly reduce the use of primary material to ensure a truly “green” battery.”—Alex Tock

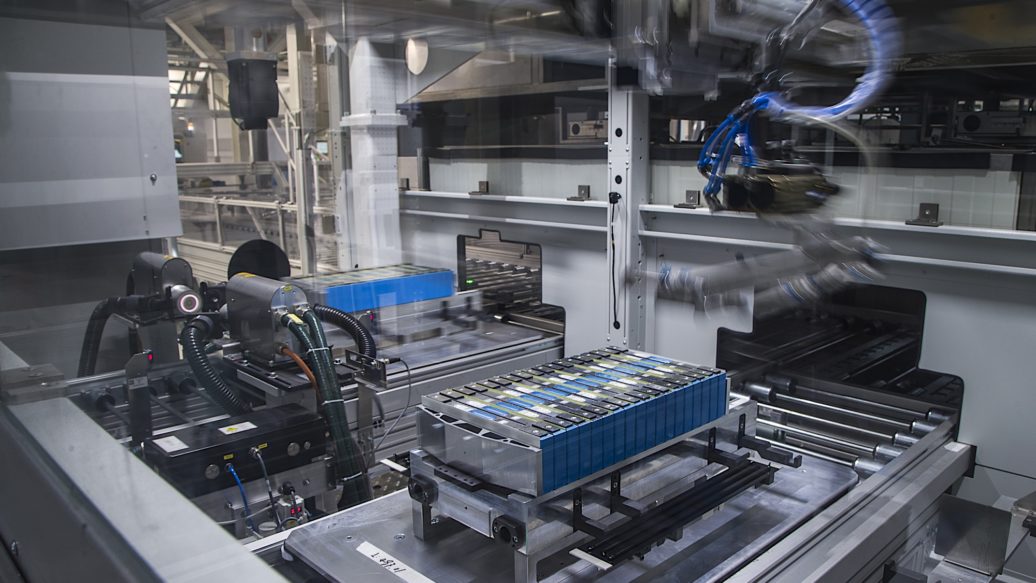

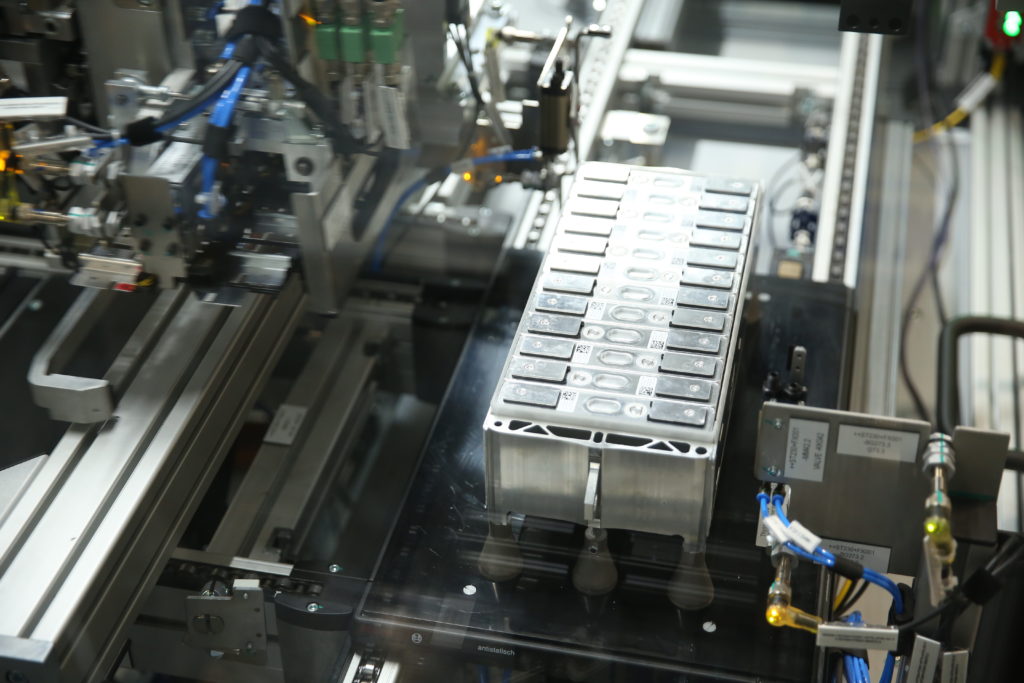

[Photos courtesy BMW AG.]