Yes, the neglected stepchild in the corner of the garage, the usurper of space, money, and attention needed by BMWs I like more, is finally coming back to life.

Almost exactly a year ago, I wrote about the dead 1974 Lotus Europa Twin-Cam Special I bought in a weak moment as a present to myself in June 2013 after my first book was published. I described how I knew that the car had a seized engine, but was thinking with a BMW 2002 owner’s mindset where used engines can be procured cheaply (how quickly I learned the painful lesson that there are no cheap used Lotus Twin-Cam engines!). I then set out to rebuild the original motor in a cost-contained fashion (HAHAHAHAHAHA, oh god that’s funny). At the end of that piece, I reported that the machine shop which had had the engine block for an embarrassingly long time called and told me that the block was ready. After what seemed like an eternity, I considered the rebuild project officially front-burnered.

I just didn’t realize that the burner was broken.

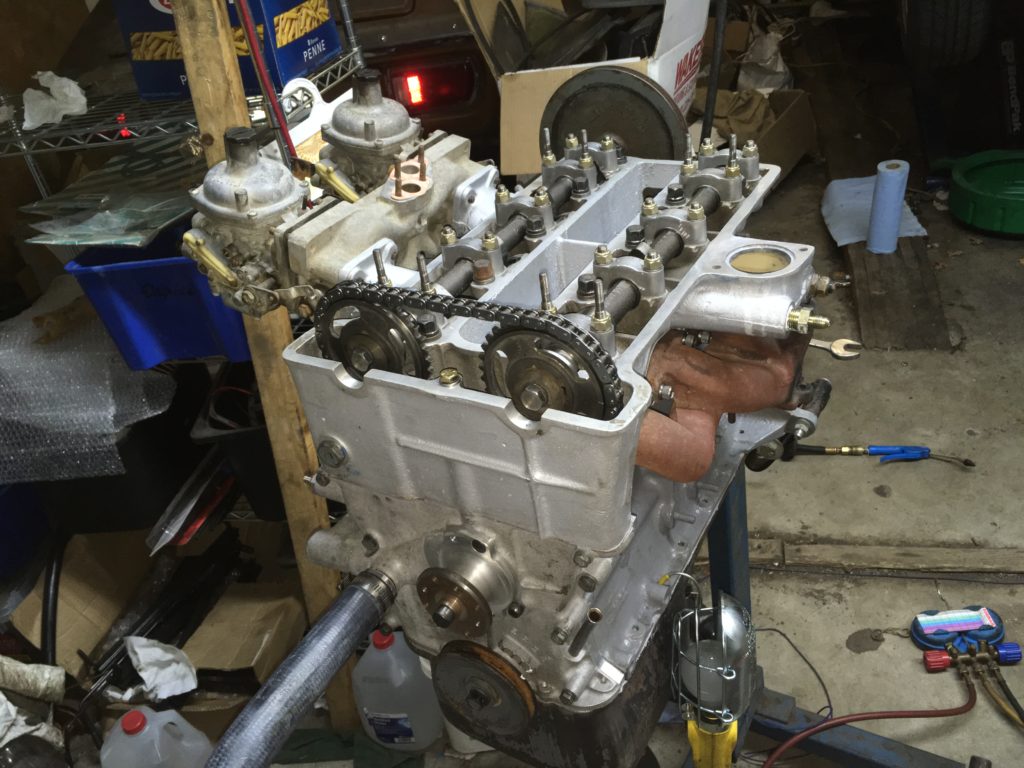

Oh, initially I made a lot of progress, to be sure. I assembled the block in short order; that part of the process was fairly conventional. The laying in of the crankshaft, the gapping of the rings, the insertion of the assembled pistons and rods through the cylinder bores, the checking of bearing clearances with Plastigauge, the measurement of crankshaft end play—all of that was little different than it was for any of the BMW engines I’ve rebuilt. I’d had the machine shop assemble the head, so one would think that I simply needed to slap on a head gasket, drop the head onto the block, torque it down, bolt on the timing covers, and be done with it. Two hours, tops, right?

Yeah… no.

Assembly of the Lotus block was straightforward. Nothing else was.

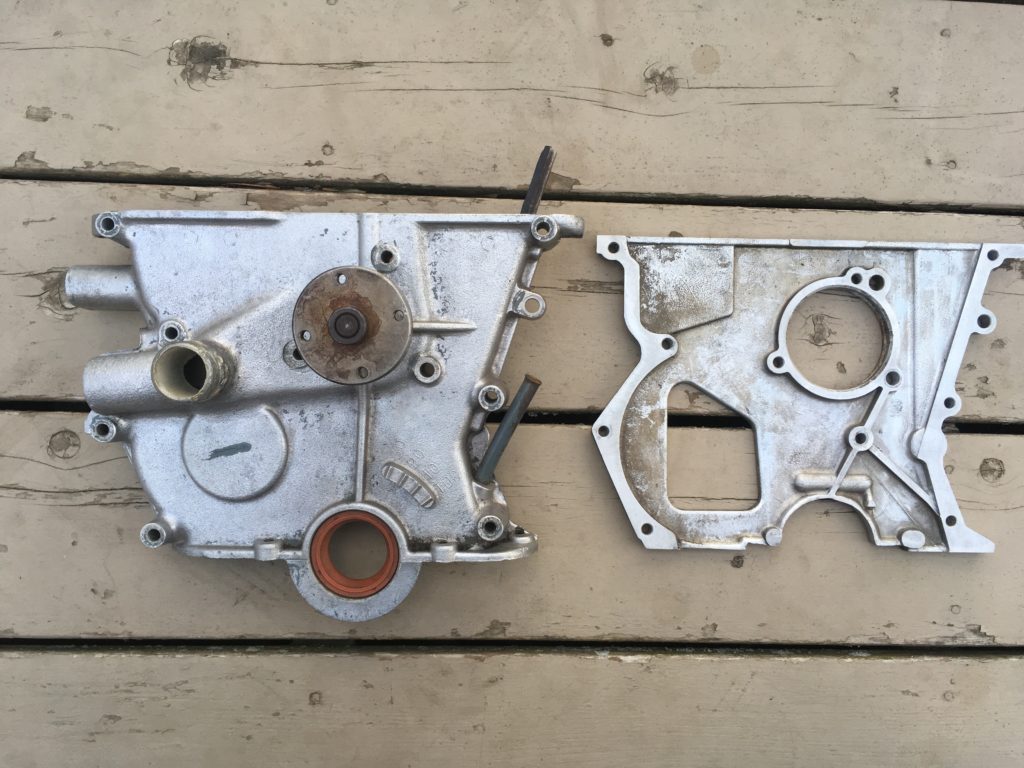

The problem is threefold. First, the Lotus twin-cam (also called “the Lotus-Ford twin-cam”) is simply a weird little engine. It’s a conventional Ford 1600 pushrod block with a low-production Lotus twin-cam head on it. The front timing cover thus has to enclose a timing chain that was never there on the original Ford cam-in-block motor, as well as allow a water pump to use the original water passage in the front of the block. It achieves this by having an inner timing cover (the “back plate”) that acts as the water seal, and an outer cover that encloses the timing chain and has an integral water pump whose seal and bearing need to be pressed into the cover.

Because the water pump isn’t a traditional bolt-on flange pump, as it is on the all-Ford version of the engine (as well as on nearly every other water-cooled engine ever built), if the pump fails, the front cover has to come off in order to replace it. And to do that, the head and pan have to come off.

And because the Europa is a mid-engine car, the engine has to come out. Yeesh, right?

The unusual outer and inner timing cover have an integrated water pump.

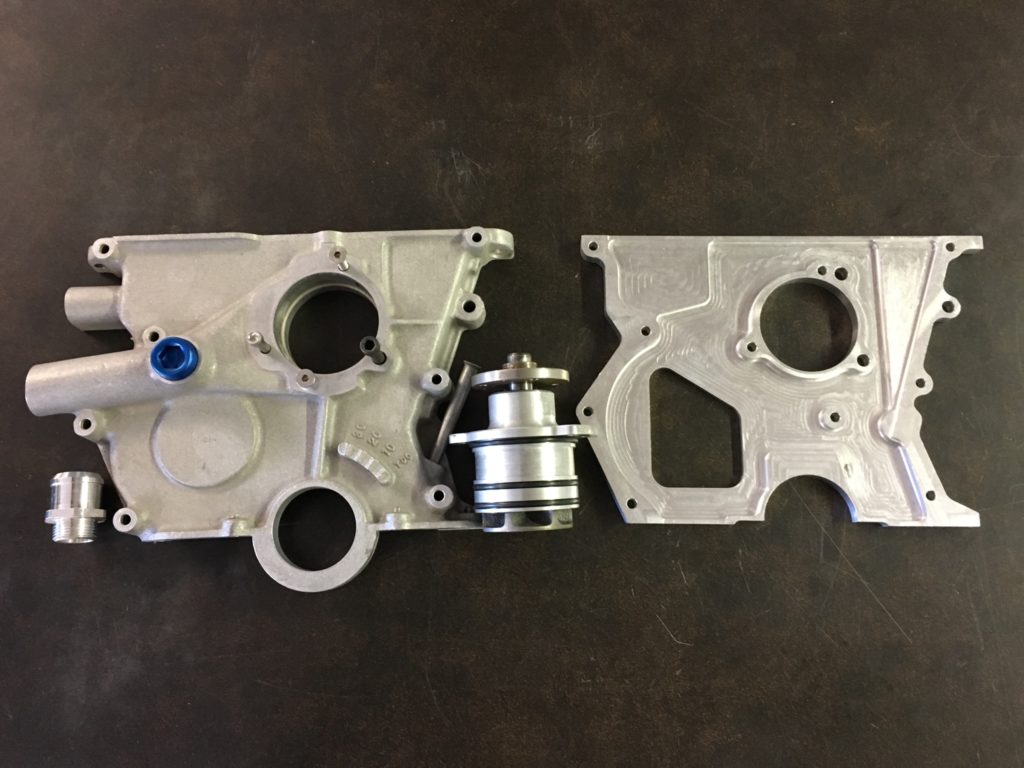

The way around this nightmare is to use an aftermarket cartridge-style water-pump kit that comes with a custom set of inner and outer timing covers. Installing such a kit allows you to easily change the water pump with the engine in the car. The problem is that only two companies make them: Burton Power in England and Dave Bean Engineering in California.

When I researched, it turns out that the Europa has a different water-routing path than other Lotuses, and that only Bean made the Europa-style kit, and that it was out of stock. But with the engine already out of the car and torn down, the cartridge-style pump seemed to be the way to go.

I waited for nine months. All work on the Lotus ground to a halt.

As it happened, it was an incredibly productive nine months. With the Lotus project stalled yet again, in late May I bought back Bertha, the ’75 2002 I’d driven off from my wedding in in 1984; the car had been sitting, dead, in my friend Alex’s garage for the past 26 years. Bertha’s resurrection occupied me all summer. Then, in September, I purchased the Lama, the E28 I bought sight-unseen on Craigslist in Tampa; unbeknownst to me, it had a broken rocker arm. Resurrecting thattook me through to December. So it’s not like, while waiting for the Lotus’ water pump kit, I had nothing to do.

Finally, in mid-December, I learned that Bean’s cartridge-style water pump was back in stock. I intentionally didn’t take on any other projects. In fact, selling the Lama when I did was partially to free up space in the garage and cash to allow me to re-engage the Lotus. The pump kit arrived literally on Christmas Eve. I dived back into the Lotus project like a maniac.

The aftermarket cartridge-style water pump and its custom front timing covers.

As soon as I began fitting the new pump kit, I discovered the second problem. Due to the weird hybrid Lotus-Ford engine design, the fitment of the pieces is decidedly un-BMW-like. There are, for example, no locating dowels or pins on the block, head, or timing covers, as there are on a BMW engine, so you don’t simply slap things on, slide dowels into holes, and tighten bolts . Even when using the stock pump and timing covers, a certain amount of, as it’s called in Brit-centric circles, fettling (trimming or cleaning to make things fit) is expected.

The third problem was that this water-pump kit was part of a new batch produced by Bean, so there were some teething issues. The first of these that I discovered was that the timing chain clearly didn’t have enough room to run inside the front cover without rubbing against the aluminum boss surrounding the water pump. Bean quickly sent me another cover that had been machined for additional clearance. But many of the other issues fell into a gray area, where, when working on one of these motors and fitting a part not originally on it, a certain amount of fettling (a term that I can now use, having worn its coat of experience) is considered par for the course. Everything had to be test-fitted. I had the covers and the head on and off the engine dozens of times. The pace was glacial.

Clearly this timing chain had inadequate clearance on the left side of the water-pump bore. Other issues, though, weren’t so black and white.

Once I had the engine reassembled, I read up on the importance of pressure-testing the coolant passages. Due to the engine’s odd timing cover and water-pump arrangement, the coolant seal is provided by a thin paper gasket, a metal-to-metal interface smeared with sealant, and an O-ring , so unless you assemble everything perfectly, it’s easy for coolant and oil to intermix, resulting in the dreaded chocolate milkshake in the oil pan, the radiator, or both. It’s thus strongly advised that you pressure-test the engine prior to dropping it in the car.

The finally assembled Lotus twin-cam was ready for pressure-testing.

Because I do a lot of air-conditioning work, I’m well-versed in the mechanics of pressure-testing. The basic rhythm is that you pressurize with compressed air or nitrogen, and use a combination of techniques, including watching a pressure gauge, listening for air hissing out, and spraying with soap solution, to find leaks.

I set out to apply these techniques to pressure-testing the Lotus engine. I adapted my a/c manifold-gauge set and nitrogen bottle to be able to screw one of the hoses into a threaded port in the head. I quickly found a major leak from where some corrosion was preventing the coolant neck over the thermostat from fully sealing.

This leak was, obviously, obvious.

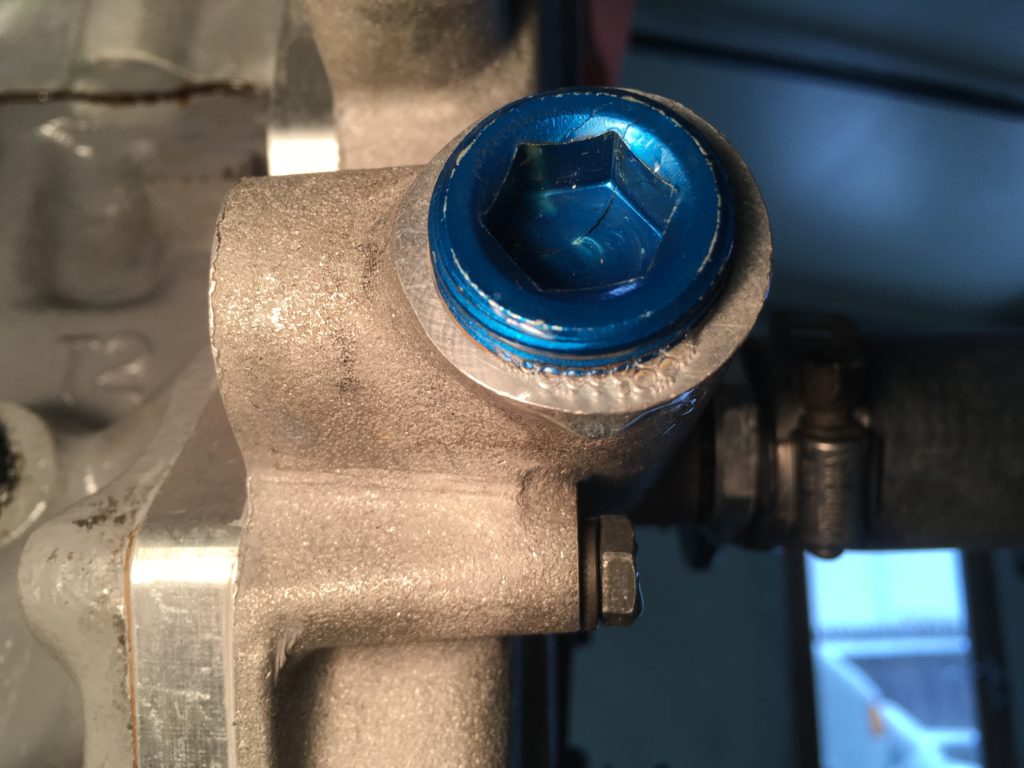

The leaks in the next layer were smaller. The Bean water-pump cover has two threaded ports, one for the water neck going to the radiator, the other for a threaded plug. It turned out that they’d been assembled at the factory with anti-seize to preserve flexibility, whereas in order to pass the kind of pressure-testing I was doing, they needed proper sealant and crush washers. Due to delays in ordering parts and waiting for thread sealant to properly cure in my garage, this part of the process alone took two weeks.

There was a small leak from one of the threaded ports on the custom timing cover.

Finally, with all the obvious visible leaks squelched, I could pressurize the system to 20 psi, spray soap solution at every seam along the head, water pump, and timing-cover interfaces, and let it sit for several hours to see if the pressure dropped and if tiny bubbles appeared along the crucial cooling system’s sealing interfaces. Initially, everything looked good, but after about half an hour, I noticed that the pressure had dropped by a few psi—and all around the block-to-head interface, I began to see the clusters of tiny bubbles that are indicative of very small leaks. When I looked carefully, I could see that the bubbles were coming from between the layers of the copper head gasket I’d used; it seemed that pressurized nitrogen was traveling through the cooling passages in the head, through the holes in the head gasket, and escaping out the layers.

Damn.

Bubbles like this indicated that nitrogen was leaking through the head gasket.

I posted the issue to a Lotus forum, and the prevailing wisdom was, basically, “calm down.” Folks advised that while the old-school layered copper head gaskets do sometimes leak a little, and that I might get a better result from a more modern head gasket, the root issue was probably that gaseous nitrogen pressured to 20 psi was more likely to leak more than liquid coolant at the system’s 7 to 10-psi pressure spec, expecting it to hold pressure and not leak at all like an a/c system would was probably unrealistic, and if it was really a problem (which it probably wasn’t), it would probably seal better after the engine was heat-cycled several times. Several friends also chimed in on Facebook offering that I’d probably never done this kind of pressure-testing on a BMW engine (I hadn’t), and if I did, I might find the same thing.

I thought about it carefully. On the one hand, it would never be easier to pull the head and install a more modern Cometic layered stainless gasket with a Viton rubber coating—but on the other hand, I didn’t know whether or not I had a real problem, and even if I did, if I found that the head gasket leaked once the engine was running in the car, it wasn’t really much more work to pull the head with the engine in the car. If, however, I was concerned about the integrity not of the head gasket but the coolant sealing of the front cover, it behooved me to do all the testing I could before I put the engine in.

I decided to do two more tests. First I flipped the engine upside down on the stand and filled it with coolant; this ensured that the coolant would gravity-feed through the holes in the head gasket, fill the passages in the head, and not expose the layers of the head gasket to gaseous nitrogen under pressure. Then I pressurized it to 20 psi and left it overnight. In the morning, to my delight, I found not a drop of coolant around the edge of the head gasket where I’d previously found the nitrogen bubbles. The pressure had dropped slightly overnight, from 20 to 17 psi, but that could’ve simply been due to the temperature falling in the garage. Dry is dry.

The inverted Lotus engine, ready to be filled with coolant.

Then I flipped the engine right-side up, let it sit while still pressurized for the rest of the day, and undid the oil drain plug that evening. No antifreeze came out of the pan.

Done. Whew!

After testing, both upside-down and right-side-up, dry as a bone.

So, although it took literally three months to do what on a BMW engine would’ve taken me two hours, the Lotus motor is ready to be mated to the transaxle and dropped into the 40-year-dormant Europa, at which point the sort-out will likely reveal that the car needs everything, as any car that hasn’t run since 1979 would.

Of course, the project is soon going to be back-burnered again, because it’s March; driving season is nearly on us, and if I’m going to drive Bertha to MidAmerica 02Fest, which I’m seriously considering doing, I’d better begin giving her some attention. After all, you need to turn on the burner under the food you actually want to eat.—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.