One of my steps in preparing Bertha for drives longer than around the block was dealing with the charging system. This involved re-bushing the alternator so tightening the belt wouldn’t cock it toward the radiator, and measuring the voltage it produced to be certain it and the voltage regulator were properly charging the battery. The resting voltage, as measured with a multimeter at the battery (or even with one of those inexpensive cigarette lighter plug-in voltmeters) should be about 12.6V, and the charging voltage with the engine running should be about 1 to 1.5 volts higher, often quoted as 13.5 to 14.2V. If the voltage doesn’t increase at all when the engine is running, the alternator isn’t charging the battery, and if you keep driving the car that way, the electrical drain from the ignition and other devices will cause the battery to run down and eventually will strand you.

Initially, I wasn’t getting any indication of charging at all; Bertha’s voltage with the engine running was the same as its resting voltage, 12.6V. Following the steps in an article I’d previously written, I performed the “full field” test on the alternator. I instantly heard the alternator load down the engine and saw the voltage rapidly swing up toward 17V, so the alternator itself appeared to be functioning.

I began looking at the regulator. On a 2002, E3, and E9, the voltage regulator is the old external mechanical style, with contact points that open and close rapidly in order to create an average voltage in the correct range. The regulator is mounted against the fender wall, and is connected to the alternator with a three-pronged plug. That creates nine things to go wrong (three connections at each end, and three wires running between them). Plus, there’s the regulator itself, which can stick open and cause the alternator to not charge the battery at all, or stick closed and allow the alternator to run full-field, which will boil the acid in the battery and generate that sickly Sulfur smell. My experience is that, on a car like a 2002 with its original 35 amp alternator and mechanical regulator, you very rarely see charging voltages in the ideal 13.5 to 14.2 volt range, but it should be at least in the high twelves, and when you turn on the headlights and the blower fan and rev the engine to where it would be for highway cruising, it certainly shouldn’t drop down below 12.6V. If it does, it’s discharging the battery.

I have a pile of regulators, seven of the mechanical ones by last count, and one newer solid-state one. I’m always afraid to throw any of them away, as bad connectors and bad grounds can often make you think you have a bad regulator. (I joke with my kids “Someday, all this will be yours.”) Initially, when I tested them in Bertha, none of them worked, but once I ran a ground strap from the alternator’s case to a convenient bolt on the head, I managed to find two regulators in the bunch that stepped the voltage up above resting voltage. I also found several that were clearly overcharging (voltage readings that zoomed up over 16V), and labeled those as “high.” I plugged in one of the good ones, began driving the car, and checked off “charging system” in Bertha’s punch list. Silly me.

Rob’s ancestral pile’o’regulators will be my kids’ inheritance.

Then, one day a few weeks ago, after using Bertha to run an errand, I came out, tried to start the car, and heard that dreaded click indicating that the battery had run down. I was only a few miles from my house, so I called Maire Anne. She rescued me and Bertha with a set of jumper cables (Maire Anne and both joked how it seemed like old times :^). The fact that the battery had run down meant that Bertha clearly still had a charging issue, and the fact that I had neither jumper cables nor my battery jump pack with me was an indication that I’d gotten kind of cocky about Bertha’s readiness. I resolved to address both issues.

When I got the car home, I repeated my tests, and still was seeing only weak charging, just a little above the resting voltage. Even though the alternator tested fine in the full-field test, I decided to replace both the alternator and external regulator and buy a more modern internally-regulated alternator. I have these in both my tii and my 3.0CSi, and I’ve been very happy with them. They remove the vagaries of the external mechanical regulator and its nine additional failure points. They also have the advantage that they put out considerably more amperage than the 2002’s original anemic 35 amp alternator. 35 amps may be fine for a bone-stock 02, but add in a beefy auxiliary cooling fan (as Bertha has), high-intensity driving lights, and a modern stereo with a power amp, and you’re pushing it.

You can either take your alternator to a local auto electric shop and have it rebuilt with an internal regulator, or buy one that’s already been rebuilt that way, or use an internally-regulated alternator from a later model car. At various times, I’ve done all of the above.

For a non-tii 2002, you can use an internally-regulated 65 amp alternator meant for an L-Jetronic M30 engine, meaning from a late 70s/early 80s 528i, 633CSi, or 733i. (Note that, for a tii, the alternator is much wider at the pivot point is different than on a stock 2002, so you either need to have your original alternator rebuilt, or use a 2002 alternator with shims or spacers.) The Bosch part number is AL41X. Rebuilt units are available on eBay as low as $150. Be sure to buy one with a pulley on it, as the pulley isn’t the same as the one from the original 2002 alternator. But I saw the equivalent Remy part (13113) for $86 shipped at both Rockauto and CarID, minus a $16 core charge.

Now, in general, the eBay rebuilds do not have a great reputation, and my advice is that if you want a high-quality rebuilt alternator, your best bet is to take yours to a local auto electric shop that you trust and have them rebuild it, but for Bertha, here, as with many things, I based my decision on cost and bought the Remy rebuilt alternator.

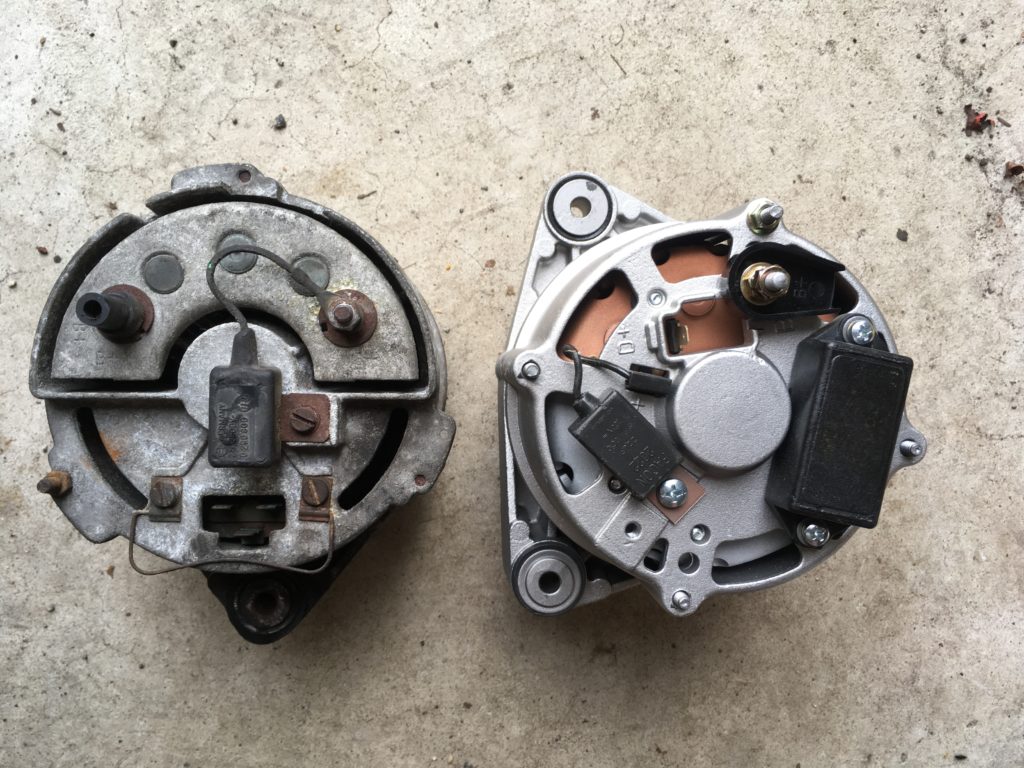

Here’s the original 2002 alternator (left) and the rebuilt internally-regulated Remy 13113 alternator (right).

The first issue was that, to my surprise, the Remy alternator didn’t quite fit the bracket on the engine. This was curious; I saw no references on bmw2002faq.com to the Bosch unit having this problem. The metal dowel that the pivot bolt goes through was just slightly bigger than the space for it in the bracket. I slightly shaved the end of the dowel with a grinder, taking off less than a millimeter, and the alternator then slipped compliantly into the bracket.

The second issue was that the fan hit the portion of the alternator shaft that protrudes through the pulley. This issue was referred to on bmw2002faq.com, with some folks reporting that they spaced the fan further out from the water pump using shims, and others saying they ground down the end of the alternator shaft. I looked at it carefully. Bertha has a pretty thick radiator, and the idea of moving the fan closer toward it was a non-starter. Grinding the end of the shaft down was quite a bit more invasive than lightly shaving the dowel through the bushing, but it was what needed to be done. With that, the new alternator fit.

I then performed the minor wiring modification needed to retrofit an internally-regulated alternator, which is to make a short jumper wire with a female spade connector on one end and a male on the other, and connect it from the D+ lug on the back of the alternator to the D+ spade on the three-pronged plug. This is needed to connect D+ to the alternator warning light on the dash, which provides the excitation current to the alternator.

With the new alternator and the jumper wire in place, I started the car, verified that the alternator warning light went out, and checked the voltage. And it was… low, like just under 13 volts. My experience with newly-rebuilt internally-regulated alternators is that they generally put out the 13.5 to 14.2 volts they’re supposed to, instead of the anemic charging of the original alternator and regulator. It didn’t seem right. Further, it seemed highly coincidental that the new alternator could be having the same problem as the old one.

I posted the issue on Facebook, and three people (Paul Muskopf, Tom Jones, and Rennie Bryant) recommended that I do a voltage drop test on the positive side, and if necessary, run a strap from the B+ terminal on the alternator directly to battery positive, as that wire and its connection can become corroded in a 43-year-old car. I did the voltage drop test, and found virtually no voltage drop. I alligator-clipped a strap from B+ to battery positive, and it made no difference.

Two other people (Rob Konig and Tony Pascarella) recommended that I do the same thing on the negative side of the battery and alternator. Now, I’d just run a new strap to the head to be certain the alternator was grounded, but I’ve learned that whenever I think “It can’t be that,” that’s a big red flag that a problem might be hiding in a blind spot.

When I clipped a test strap from the alternator case to battery negative, the charging voltage instantly jumped up to 13.6V. The head, apparently, wasn’t a good ground. I moved the alligator clip on the test strap from the battery negative terminal, along the negative cable, and down to where it attaches to the starter bracket on the block. The charging voltage stayed at 13.6V. I moved the clip to the head, and the voltage dropped back down. Gotcha. On one hand, it makes sense that the block is a better ground because the battery ground strap runs directly to the block, and the head is insulated from the block by the head gasket, but the head still has lots of metal-on-metal contact with the block. Still, the results were incontrovertible. I moved the alternator’s ground strap permanently from the head to the block. Problem solved.

I realized that a bad ground had probably had been the problem with the original alternator and external regulator all along, and that, in retrospect, I probably didn’t need to buy a new alternator. But for about $75 after the core return, I now have a new (well, rebuilt) less-troublesome internally-regulated alternator whose 65 amp output is more in keeping with Bertha’s new auxiliary cooling fan, and the big Cibié Oscar driving lights, if I ever reconnect them.

So, the fact that I said that I was afraid to throw any of the regulators away because a bad ground often acts like a bad regulator was a bit more prescient than I thought. Maybe, some rainy day when I have nothing to do, I’ll put the original alternator back in, ground it correctly to the block, re-test the pile’o’regulators, and throw out the ones that are actually bad. But if I did that, what would I have to leave my children?—Rob Siegel

Rob’s new book, Just Needs a Recharge: The Hack MechanicTM Guide to Vintage Air Conditioning, is available here on Amazon. His previous book Ran When Parked is available here. Or you can order personally inscribed copies of all of his books through Rob’s website: www.robsiegel.com.