Two years worth of collective work between the BMW Design Department and the Massachusetts Institute of Technology’s Self-Assembly Laboratory has made liquid-printed pneumatic material a reality. Conceived as a substance that can “self-transform, adapt and morph from one state to another,” according to BMW, the new material and underlying concepts have radical potential that could allow manufactures to completely rethink their approach to vehicle interior construction and functions.

While the idea may sound like science fiction, it’s not a particularly new one for BMW; those well versed with the BMW Vision Next 100 concept might connect the dots in terms of how future developments of similar materials and manufacturing methods might play a role in upcoming mobility concepts.

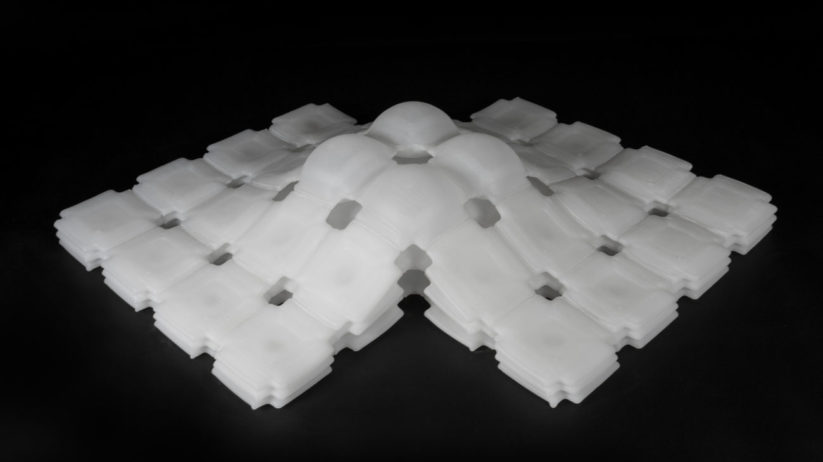

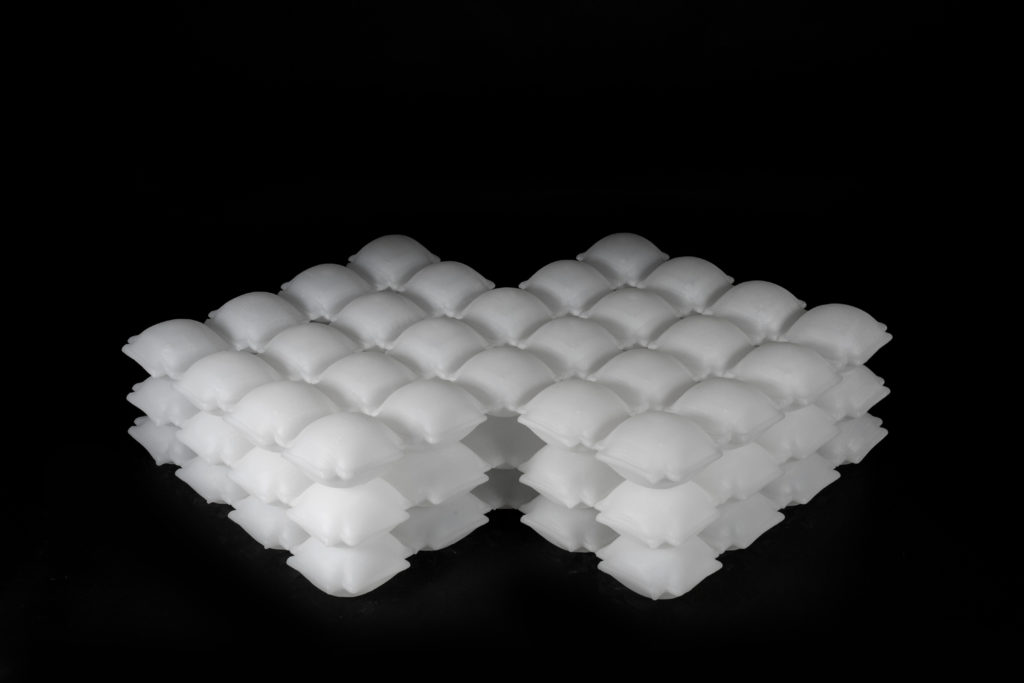

Things remain in a very rudimentary state, but the possibilities exhibited by this latest breakthrough remain impressive. Depending on the amount of air pressure in the system, the silicon-printed material—which conjures up visions of bubble wrap and other packing materials—is actually controllable. In addition to the ability to take a variety of shapes, there is also fine adjustability that applies to stiffness, as well as the overall pattern of the individual air chambers. The substance is reportedly able to be adapted to nearly any size or shape, which can of course take any number of final forms.

Constructed using a silicon-liquid process highlighted in the video below, 3D-printing methods now allow the creation of the sealed balloon-like cells that give the new material its magic properties. When it comes to applicability in the mobility realm, BMW is thinking big. The car or transportation module of the future is continuously evolving along with the changing needs of society, but adaptability seems to be an underlying current in things going forward. In addition to simple things like transformable cushioning and variable impact performance, the possibility of facilitating changes that used to require a completely different platform might also become a reality. For example, the number of seats a future BMW vehicle has might be widely variable based on what’s needed in a given circumstance, with an operator being able to select between an insulated cargo area or rows of benches.

The video below highlights some capabilities of this early form of liquid-printed pneumatic material. The level of control and variability is impressive on its own, but the future possibilities of how fully developed versions might impact our lives are even more captivating.—Alex Tock

[Photos and video courtesy of BMW Group.]